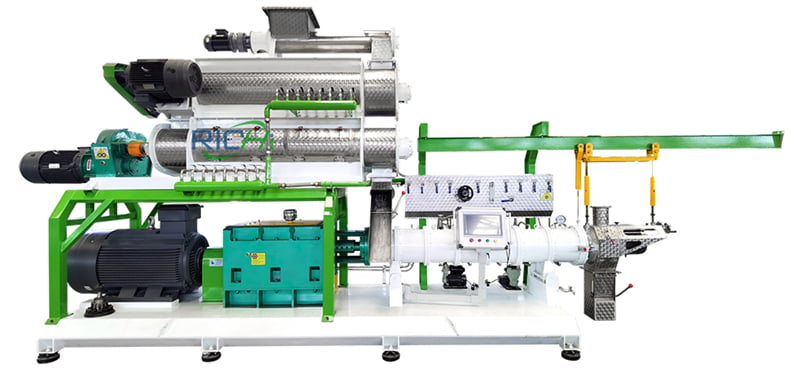

Floating fish feed extruder machine

The floating fish feed extruder machine is mainly used for the production of all kinds of aquatic feed pellets, pets, and other feed pellets such as floating fish feed pellets, shrimp feed pellets, crab feed pellets, and frog feed pellets.

- Capacity: 1-12T/H

- Power: 75-355KW

Different types of floating fish feed extruder machine

The equipment can be divided into two categories, including single screw floating fish feed extruder and twin screw floating fish feed extruder. When buying a floating fish feed extruder, we will encounter a problem – is it to buy a twin screw floating fish feed extruder or a single screw fish feed extruder? What is the difference between the two?

The principle of the twin screw fish feed extruder and single screw fish feed extruder is the same as that of the product obtained by extruding rapid expansion and cooling from the mold after high heat extrusion. The difference in function mainly depends on the size of the extrusion force, and the corresponding equipment is selected for the type of extruded feed.

A twin screw fish feed pellet making machine is generally used in the production of aquatic and pet feed pellets with high added value, such as eel, turtle, and juvenile feed.

Twin screw floating fish feed extruder machine

The raw materials are conditioned at high temperatures and then sent to the expansion mechanism. The double-screw fish feed extruder is driven by a pair of parallel screws to push the material forward. The material from the hopper into the barrel, as the screw rotates, along the direction of the groove forward transport, is gradually compacted. The material is strongly stirred, mixed, and crushed between the two screws and between the screw and the cylinder.

The material temperature rises and begins to melt until they all melt. As the chute space is further smaller, the material is further heated and boosted, and the raw starch is fully gelatinized. When the materials are instantly extruded from a certain shape of the die hole, the pressure is released quickly, the water evaporates sharply, the material expands accordingly, and the water is quickly lost from the material. The product is quickly cooled to about 80℃ so that it is solidified and maintains its expanded shape.

The floating fish feed extruder is the equipment for producing aquatic feed pellets. With the development over time, feed extrusion technology is becoming more and more mature. RICHI Machinery has a professional technician team and can provide clients with fish feed extruders of 1-12T/H capacities.

1-2T/H floating fish feed extruder

Capacity:

1-2T/H

Main Power:

75KW

3-4T/H fish feed extruder

Capacity:

3-4T/H

Main Power:

90KW

4-5T/H fish feed pellet making machine

Capacity:

4-5T/H

Main Power:

160KW

6-7T/H fish feed extruder

Capacity:

6-7T/H

Main Power:

200KW

8-10T/H floating fish feed extruder machine

Capacity:

8-10T/H

Main Power:

315KW

10-12T/H fish feed pellet making machine

Capacity:

10-12T/H

Main Power:

355KW

The parameters of the equipment are as follows:

Single screw floating fish feed extruder

A single screw floating fish extruder machine is the most basic extruder in the production of aquatic feed pellets with a simple structure and low price. Also, it is easy to manipulate and control.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The advantages of the fish feed extruder

01

Due to the convenience of opening, the wearing parts can be found at any time, so as to carry out effective maintenance or replacement. It will be discovered when there is a problem in extruding the product, resulting in unnecessary waste.

02

It has the advantages of high torque, high speed, and low energy consumption. High speed brings high productivity. Also, it has a unique advantage in processing high-viscosity and heat-sensitive materials.

03

The main motor adopts frequency conversion control. And the screw can adjust the speed, suitable for different formulations, such as sinking material, semi-floating material, and floating material.

04

The twin screw fish feed extruder adopts a PLC touchscreen control system which is simple to operate.

05

The twin-screw floating fish feed extruder machine has many advantages, such as wider adaptability of raw materials, wider adaptability of products, better internal and external quality of products, higher output under the same power, better ripening and homogenizing effect, less wear of vulnerable parts, and lower production cost. In the feed processing enterprises to build and expand special fish feed production lines such as aquatic feed and pet feed pellets, there is no doubt to choose a floating fish feed extruder.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The project case of the floating fish feed extruder

The floating fish feed extruder machine is a kind of fish feed equipment that practitioners of various fishery and aquaculture industries want to know about. The fully automatic fish feed production line produced by RICHI Machinery is professional production equipment for floating fish feed developed by our company according to market demand. The equipment has the advantages of low energy consumption, large output, labor saving, simple operation, etc. It is suitable for the investment and use of aquaculture entrepreneurs.

Iran

Floating fish feed extruder machine in Iran

- Name: floating fish feed plant in Iran

- Capacity: 1.5-2t/h floating fish feed and 5-6t/h shrimp feed

- Feed pellet size: 1-12mm

- The installed period: 90 days

- The operating worker: 4-5 person

Uzbekistan

fish feed extruder in the Fish feed production line

- Total power: 298kw

- Raw material: fish meal, peanut meal, soybean meal, premix, etc

- Feed pellet size: 1mm, 2mm pellet

- Workshop size of this project: 8m*5m*14m (L*W*H)

- Operate worker in this line: 5-6 person

Ecuador

Floating fish feed pellet making machine in the 1-2T/H fish feed production line

- Total power: 58kw

- Raw material: fish meal, bone meal, soybean meal, cotton meal

- Feed pellet size: 3mm shrimp and fish feed pellet

- Workshop size: 9m*6m*13m (L*W*H)

- Operate worker in this line: 2 person

China

Fish feed extruder machine in the fish feed production line for shrimp and prawn feed production

- Date: July 2016

- Capacity: 27-28T/H

- Feed Size: 1-4mm

- The installation period: 60 Days

- Control Mode: Automatic

The fish feed extruder applied in the fish feed production line

The fish feed production line is used to produce various pet food, floating fish feed, and sinking fish feed. It has the characteristics of simple operation and accurate parameter control. The design of granulating process and the selection of relevant floating fish feed extruder machines are important factors affecting the quality of aquatic feed. In a fish feed production line, the floating fish feed extruder plays an important role in pellet quality. The reason why the fish feed production line can produce high-quality floating feed mainly depends on the fish feed pellet making machine.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The main equipment of the fish feed production line

With the rapid development of the economy, the demand for various kinds of aquatic feed is increasing rapidly, and it is moving towards commercialization and scale. The market is extremely hot. According to this market demand and our own experience in the research and development of extrusion machinery, RICHI Machinery has developed a variety of types of aquatic feed production equipment. There are many machines and equipment used to produce floating fish feed pellets, mainly hammer mill, mixer machine, twin-screw fish feed extruder, dryer, etc.

Feed grinder machine

Capacity:

1-2T/h

Main Power:

22KW

A machine that pulverizes the raw materials for fish grain production, such as corn, sorghum, wheat, beans, crushed cake and other materials..

Feed mixer machine

Capacity:

1-2T/h

Main Power:

22KW

Add a certain proportion of water and additives to the crushed fish grain raw materials, and mix them evenly.

floating fish feed extruder machine

Capacity:

1-2T/h

Main Power:

22KW

The mixed raw materials are extruded through a feed mold under a high temperature and high-pressure environment to form feed pellets.

Dryer

Drying is one of the most important processes in extruding feed processing. The moisture content of feed pellets just extruded from the fish feed extruder is very high, reaching more than 22%. The dryer must first remove more than 10% of the moisture, and then after cooling treatment, it can ensure that it reaches the qualified product quality. Moreover, the temperature can be adjusted by itself to dry the feed particles to increase the shelf life.

Spraying machine

Capacity:

1-2T/h

Main Power:

22KW

Including an oil injector that sprays oil and food attractant, mainly sprays oil on the feed surface, and removes burrs on the surface of feed pellets to make the feed particle surface smoother.

Cooling machine

Capacity:

1-2T/h

Main Power:

22KW

Reduce dried feed pellets’ surface temperature from 80°C to slightly above room temperature for 3°C-5°C, promote oil solidification, and facilitate packaging.

Vibrating screener

Capacity:

1-2T/h

Main Power:

22KW

Screening out the surplus external materials and granular slag in grain, feed, flour, and food industries to realize material grading.

FAQ about the floating fish feed extruder machine

How to maintain the twin screw fish feed extruder?

In order to prolong the service life of the twin-screw floating fish feed extruder machine, it is necessary not only to operate strictly according to the operating procedures but also to clean and maintain it regularly. What are the specific cleaning and maintenance methods?

01 Resin cleaning method

This method is to clean the machine with resin, such as polyester resin or epoxy resin. This is generally used when the fish feed pellet making machine has been used for a period of time. When some materials remain on the screw or the screw cylinder and are gelatinized, the extrusion speed of materials becomes slow, and the color difference of the color change varieties is large, this method can be used.

02 Non-resin cleaning method

This method uses materials such as rice, corn, sawdust, and toilet paper that have certain friction and are easy to crush. When the fish feed extruder is heated to the normal extrusion temperature, the friction between these materials and the screw and the screw barrel is used to remove the residues on the surface of the screw and the screw barrel.

Experience shows that the hardness of rice husk is high and the friction force is great, compared with the effect of machine cleaning. After cleaning with this method, it is necessary to open the screw barrel to check the cleaning condition.

How to maintain the twin-screw floating fish feed extruder after knowing how to clean it?

- After using the machine for a period of time, a comprehensive inspection shall be carried out to check the tightness of all screws.

- In case of power interruption in production, the main drive and heating will stop. When the power supply is restored, all sections of the barrel must be reheated to the specified temperature and kept warm for a period of time before starting the extruder.

- After the extruder has been used for 500 hours, there will be iron chips or other impurities in the reduction gearbox. Therefore, the gears should be cleaned and the lubricating oil of the reduction gearbox should be replaced.

- The screw can only be started at low speed, and the idling time shall not exceed 3 minutes.

- No sundries are allowed in the materials, and hard objects such as metal, sand, and gravel are strictly prohibited from entering the hopper and extruder.

Do you know if a fish feed extruder machine can make floating fish food pellets?

Extrusion processing is a processing technology in that raw materials are processed by high temperature, high pressure, and instant ripening, integrating transportation, crushing, extrusion, mixing, shearing, high-temperature disinfection, and molding. And it can process viscous, high-fat, high moisture raw materials. This is incomparable to the general production process, so it is increasingly used in the production of high-grade feed and food such as aquatic feed, pet feed, special breeding, etc.

So what are the advantages of the expanded aquatic feed pellets produced by the fish feed pellet making machine?

01

Good water resistance

The structure formed in the expansion process makes the expanded aquatic feed pellets stable in water. Whether it is the sinking feed or the floating feed, it can not collapse after soaking in water for 12 hours, which can maintain the quality of aquaculture water. It not only greatly reduces the waste of feed, but also provides a good environment for the healthy growth of aquatic animals.

02

Higher digestibility

The changes in starch, protein, and other substances caused by high temperature, high pressure, and strong shearing during the processing of expanded feed have improved the digestibility of such substances. The starch gelatinization degree of expanded aquatic feed is generally above 85%, while that of ordinary hard-grain aquatic feed is only about 40%. The digestibility of starch alone is far higher than that of ordinary hard-grain aquatic feed. Strong extrusion can degrade some compact cellulose and keratin, release indigestible nutrients, and greatly improve digestibility.

03

Excellent palatability

The proper temperature and pressure during the expansion process make the finished feed granules porous and even in texture, and produce some flavor substances, which stimulate the appetite of aquatic animals and increase their intake.

04

Widen the scope of raw material utilization

The leftovers from the food industry, brewing industry, agriculture, and other industries are not easy to be processed into other forms of aquatic products due to the excessive water, oil, or cellulose content. The twin-screw fish feed pellet making machine can make full use of them and enrich the feed resources.

When building or rebuilding the fish feed production line, the selection of a twin screw floating fish feed extruder should be considered first, and the equipment should be selected according to the production capacity and investment. During the transformation of the fish feed production line, it is also necessary to consider whether the production capacity and production effect of the original feed grinder machine, cooling machine, and dryer can meet the requirements of the selected fish feed pellet making machine and whether the existing equipment can be used to reduce investment.

RICHI Machinery can provide you with a floating fish feed extruder machine of various capacities. We can help you with plan design, workshop layout, equipment production, installation, training to after-sales. If you are intending to invest in the aquatic feed pellet production industry, just contact us.

Why Choose RICHI Machinery?

RICHI Machinery owns CE/ISO/BV certifications. RICHI Machinery has its own factory and professional production equipment. It is an industrial group that mainly focuses on animal feed pellet machinery, biomass pellet machinery, wood pellet machinery, etc. RICHI pellet machine is sold in many countries and regions in the world. We also provide various solutions for clients based on their different raw materials, production capacity, the kinds of pellets, etc.

RICHI Machinery also provides a one-stop service. It has a professional system from structural design, equipment production, and installation to after-sales service.

Feed machinery structural design and equipment production

With more than 20 years of experience in the pellets equipment industry, RICHI Machinery can offer you a professional technical recommendation. On the basis of site surveys for customers, we can provide clients with a detailed project design scheme, design site foundation drawings, and so on.

Feed machinery installation and training

RICHI Machinery has a complete technology training and guiding system. Our technical workers can provide you with free training about how to operate the equipment, and how to do basic maintenance and protection of the equipment.

After-sales service

RICHI Machinery always concentrates on the production of pellet production equipment. And we have a professional and highly-skilled after-sales service team and a modern and information-based after-sales management system. From the supply of common accessories, and equipment maintenance to repair, we provide a one-stop service to release you out of trouble.

RICHI Machinery, as an equipment manufacturer, would offer you all-around service. If you want to learn more about the floating fish feed extruder machine, just contact us directly and we are always here for you.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production