Animal Feed Pellet Press

Animal feed pellet press is the core equipment in modern animal husbandry.

RICHI MACHINERY

General Production for animal feed pellet press

RICHI Machinery not only provides stable and reliable animal feed mill equipment but also customizes feed production solutions based on your raw material and production requirements, which ensures your purchase and operation are carefree.

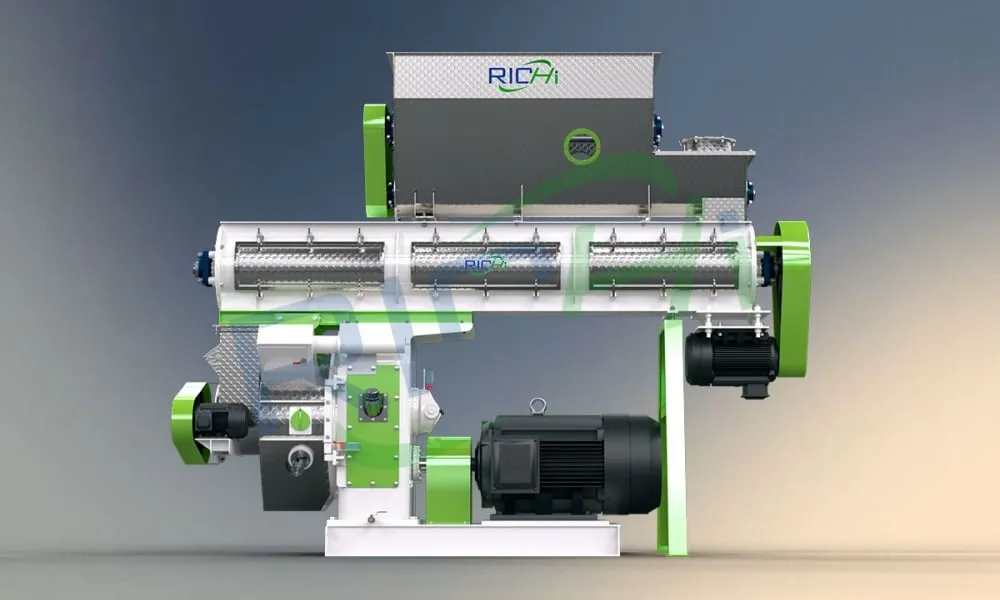

RICHI Animal feed pellet press For Sale

RICHI Animal feed pellet presses process various raw materials into palatable and nutritionally balanced feed pellets. Whether it’s common livestock and poultry feed ingredients (corn, soybean meal, rice husks, etc.) or aquatic feed (high-protein components like fish meal and shrimp meal), RICHI equipment fully meets the nutritional needs of all animals.

With the development of large-scale farming, animal feed pellet presses have become core equipment in modern animal husbandry, specifically designed to transform various powdered feed ingredients into high-density pellet feed.

This equipment employs advanced mechanical compression technology, converting powdered raw materials such as corn, soybean meal, and wheat bran into uniformly sized feed pellets through conditioning, compression, and shaping processes. This significantly enhances feed utilization value and farming profitability. Whether for large-scale farming companies or medium farms, it is always able to reduce feed costs and increase farming profitability through the use of feed pellet mill.

RICHI MACHINERY

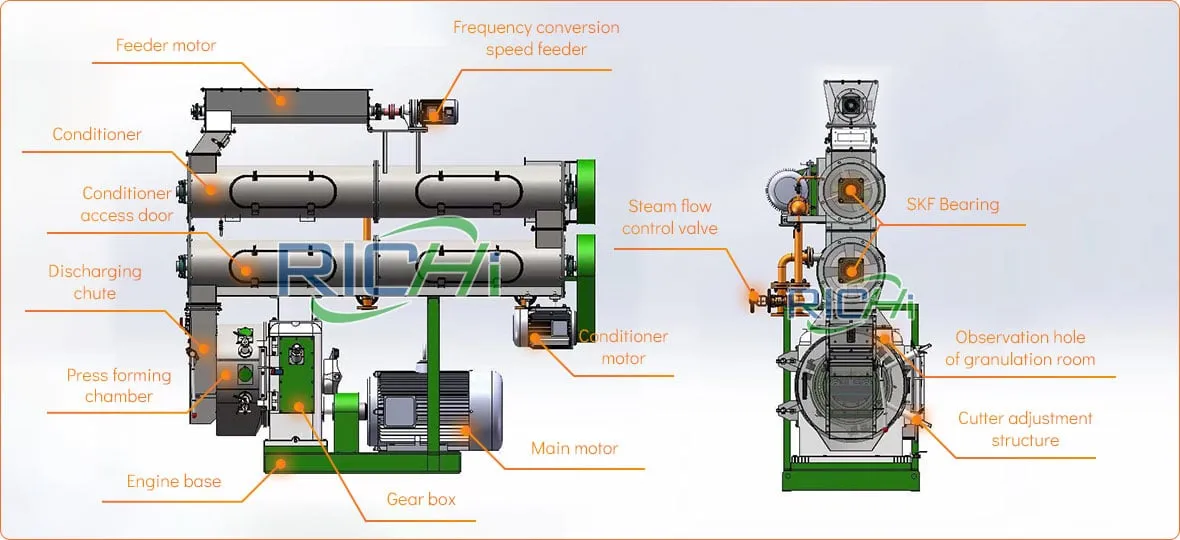

Core Components of animal feed pellet press

Next, let’s explore the core components of RICHI Machinery’s SZLH series feed pellet press. We design each unit with high quality materials, such as stainless steel construction, Siemens motors, and SKF bearings. The high quality configuration and perfect coordination of these core components ensure the efficient and stable operation of the animal feed pellet press. Selecting good core components not only boosts productivity but also reduces maintenance costs, which provides reliable support for your farming business.

Spindle Drive System

As the power core of the equipment, it employs high-quality alloy steel gears to ensure smooth and reliable transmission. Equipped with a forced lubrication system, it guarantees adequate cooling and lubrication for gears and bearings during high-speed operation, which prolongs service life.

Ring Die

The ring die is a critical component for pellet forming, which is made from high-quality alloy steel through precision machining. The die’s aperture size and open area ratio are scientifically calculated to ensure both production output and pellet density and forming efficiency. The surface undergoes special heat treatment for strong wear resistance.

Siemens Motors

We utilize Siemens motors as the power source, which provides reliable power support for animal feed pellet presses. Famous for their high efficiency and stable performance, Siemens motors ensure the feed pellet press maintains consistent productivity for a long time.

Feeding System

With frequency-controlled feeding, you can adjust feeding speed and volume according to your production needs to maximize the feed pellet press’s capacity.

Cutting Device

It is installed on the outer side of the ring die to cut the extruded strip material into pellets of the desired length. The blades are made of wear-resistant materials, and the pellet length can be controlled by adjusting the blade length.

Electronic Control System

It adopts touchscreen control to achieve automated equipment operation. It enables real-time monitoring of equipment status, displays critical parameters such as output and temperature, and features automatic fault diagnosis and alarm functions.

Animal Feed Pellet Press working Video

Animal feed pellet press operates on the principle of mechanical compression molding. Through processes of tempering, pressing, and forming, it transforms powdered feed ingredients into high-density pellet feed. Now we will demonstrate how the animal feed pellet press operates efficiently.

● RICHI MACHINERY

Animal Feed Pellet press Working Principle

The entire process comprises four critical steps, each directly impacting the quality and yield of the final product.

Feeding

Based on the formulation requirements for different animal feeds, the animal feed pellet press employs intelligent control to automatically adjust the feed rate. This ensures that various feed powders are mixed proportionally without disrupting production or causing congestion due to overfeeding.

Tempering

The addition of steam not only makes the raw materials easier to shape but also activates their nutritional components, which improves the digestibility and absorption rate of the feed. Simultaneously, it effectively eliminates harmful microorganisms, which makes the feed safer and more nutritious.

Extruded

This is the core step in pelleting. The blended raw materials are extruded through the special molds under pressure to form uniformly sized pellets.

Cutting

Pellets emerging from the mold form continuous strands that must be cut to the appropriate length. The cutting device precisely regulates pellet dimensions, which ensures uniform feed size. This facilitates packaging and transportation while enabling animals to consume the feed efficiently without waste.

RICHI MACHINERY

Model Specifications of animal feed pellet press

Animal feed pellet press can be classified based on animal species.

- Poultry and Livestock: Pigs, Chickens, Ducks, Geese, Cattle, Sheep, Rabbits

SZLH Series Feed Pellet Press is mainly suitable for the production of animal feed pellets livestock, poultry, rumination, aquatics.

- Ruminants: cattle, sheep, horses, camels

SZLH Series Grass Pellet Press is mainly suitable for the production of ruminant feed pellets with various grass powders and raw grains such as forage, alfalfa, straw, hemp, hops and so on.

- Aquatics: Fish, shrimp, crab

SZLH Series Shrimp Feed Pellet Press is mainly suitable for the production of shrimp feed pellets. According to the characteristics of shrimp material to design the speed of the ring die, which greatly improve the production capacity of the feed pellet press and the appearance and internal quality of the shrimp pellet.

All of the above animal feed pellet presses are ring die feed pellet press. This feed processing machinery features high output and low energy consumption, which is mainly suitable for processing various animal feed pellets in large and medium-sized feed mills.

Parameter Table of RlCHl SZLH animal Feed Pellet Press

Here are the specifications for feed pellet press. If you are not sure how to select the appropriate model, please contact us directly.

| 型号 | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Main Motor Power (kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Modulator Power (kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Inner Diameter of Ring Mold (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellet Diameter (mm) | 2~12 | |||||||

| Capacity (T/H) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

RICHI MACHINERY

Animal Feed Pellet Press Price

RICHI Machinery’s SZLH series animal feed pellet press range in price from $7,000 to $100,000.

Specific price quotations depend on configuration requirements and purchase volume. We recommend providing your production capacity requirements and raw material specifications so we can recommend the most suitable model for your needs.

Small-scale equipment

Production Capacity: 1-4 t/h

Power: 22-37 kW

Price Range: ¥28,000 – ¥65,000

Applications: Family farms, small-scale livestock operations, startup ventures

Medium-scale Equipment

Production Capacity: 5-25 t/h

Power: 55-250 kW

Price Range: ¥75,000 – ¥400,000

Applications: Professional farms, small feed processing plants

Large-scale Equipment

Production Capacity: 25-45 t/h

Power: 250-355 kW

Price Range: ¥400,000 – ¥800,000

Applications: Large aquaculture groups, feed production enterprises, Professional feed mills

Advantages of Animal Feed Pellet Press

We understand that selecting a animal feed pellet press is not merely choosing equipment, but selecting a long-term partner. Therefore, we pursue perfection in every detail, which reflects our deep understanding of customer value. Next, let us introduce the core advantages of our animal feed pellet press in detail.

Wide Applicability

The SZLH series animal feed pellet presses are suitable for producing feed pellets for poultry, livestock, ruminants, aquatic animals, and other animal feeds. Not only can they process a wide variety of raw materials for various animal feeds, but they also offer animal feed pellet presses with different capacities to meet your production needs.

Conducive to Storage

The pelleting process removes moisture, resulting in lower moisture content in pellet feed compared to the original material. This not only saves storage space but also prevents moisture absorption and extends shelf life. Additionally, loose feed tends to generate dust, and the reduction of dust pollution through pelleting creates a cleaner farming environment and facilitates transportation.

Enhance nutritional value and digestibility

After processing, the produced feed pellets with high hardness, smooth surface, and fully cooked interior improve the digestion and absorption of nutrients. Under high-temperature and high-pressure, harmful bacteria such as Escherichia are effectively eliminated, which makes it easier for animals to digest and absorb.

Good Appetite

Additionally, high-temperature processing provides feed with a special aroma, significantly enhancing appetite and stimulating animal appetite. This is particularly beneficial for young animals and livestock with poor appetites,which promotes healthier growth.

RICHI MACHINERY

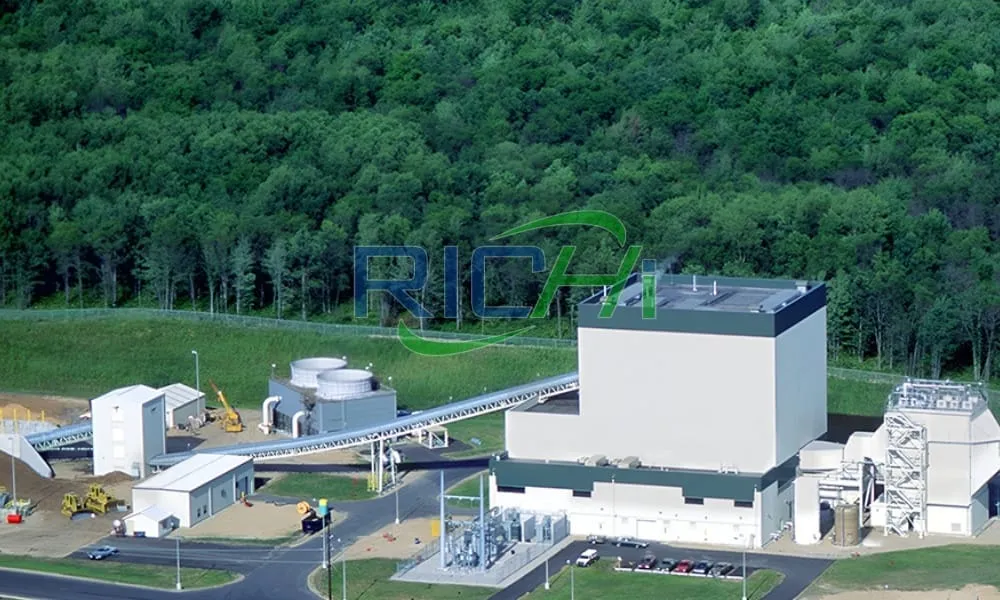

Cases For Animal Feed Pellet Press

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises. We have provided animal feed pellet production services to thousands of clients.

Below are some projects we have done. If you are interested in these projects, please contact us for more details.

10-15T/H Feed Pellet Press in Uzbekistan

3-4T/H Feed Pellet Press in Zimbabwe

3-5T/H Feed Pellet Press in Indonesia

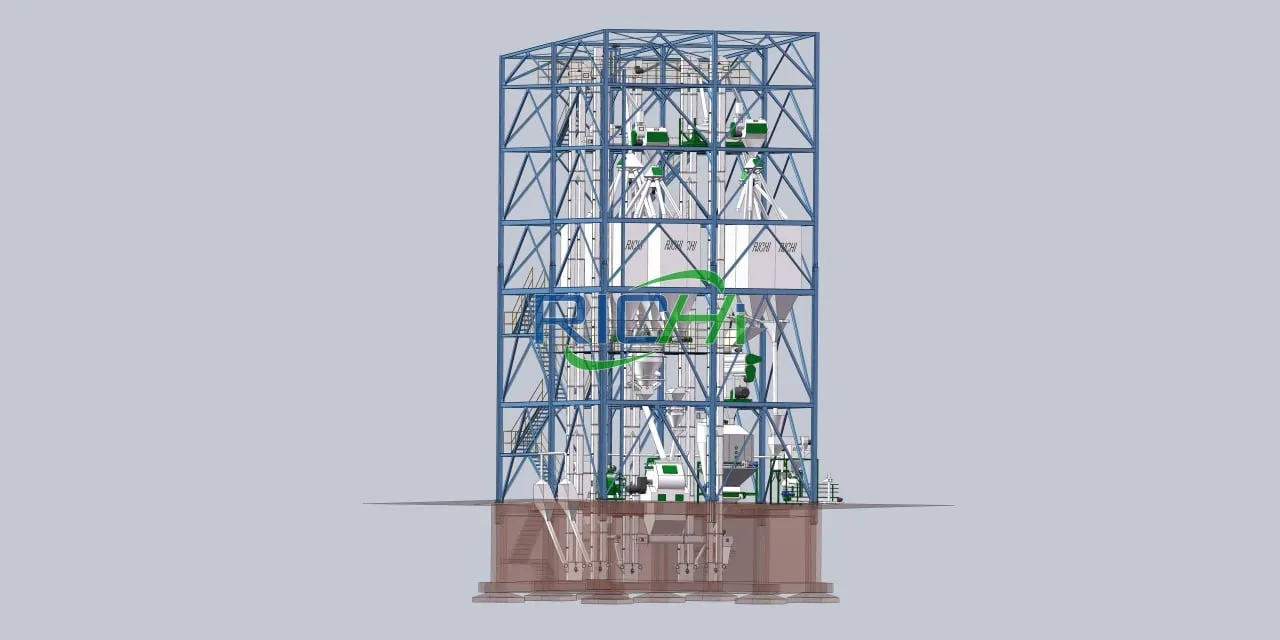

Full-Process Feed Pellet Production Line and Major Equipment

The feed pellet production line is a complete set of equipment capable of producing various animal feed pellets, which covers a wide range of farmed animals including chickens, cattle, sheep, shrimp, etc. With flexible production specifications and robust capacity, this line processes feed pellets ranging from 2 to 12 millimeters in size, and with an hourly output of 1 to 100 tons, which meets diverse production demands. It is suitable for applications of varying scales, including small, medium, and large feed processing enterprises and farms, which makes it an ideal solution for achieving efficient and standardized feed processing.

There are various kinds of feed pellet plant lines various from the production process, output, configuration, etc. Next, I will take the general animal feed pellet production line process as an example to explain to you.

1.Crushing- SFSP Series Water-drop Hammer Mill

First of all, it is necessary to crush the food materials which are prepared according to the formula. This not only can ensure the pelleting effect of the feed pellet press, but also can make the raw materials easier to digest and absorb by the animals.

2.Mixing– SLHJ or SLHY Series Paddle Mixer

After crushing, we need a feed mixer to mix the crushed raw materials evenly. It can make the made feed pellets nutritionally balanced, and promote the healthy growth of animals.

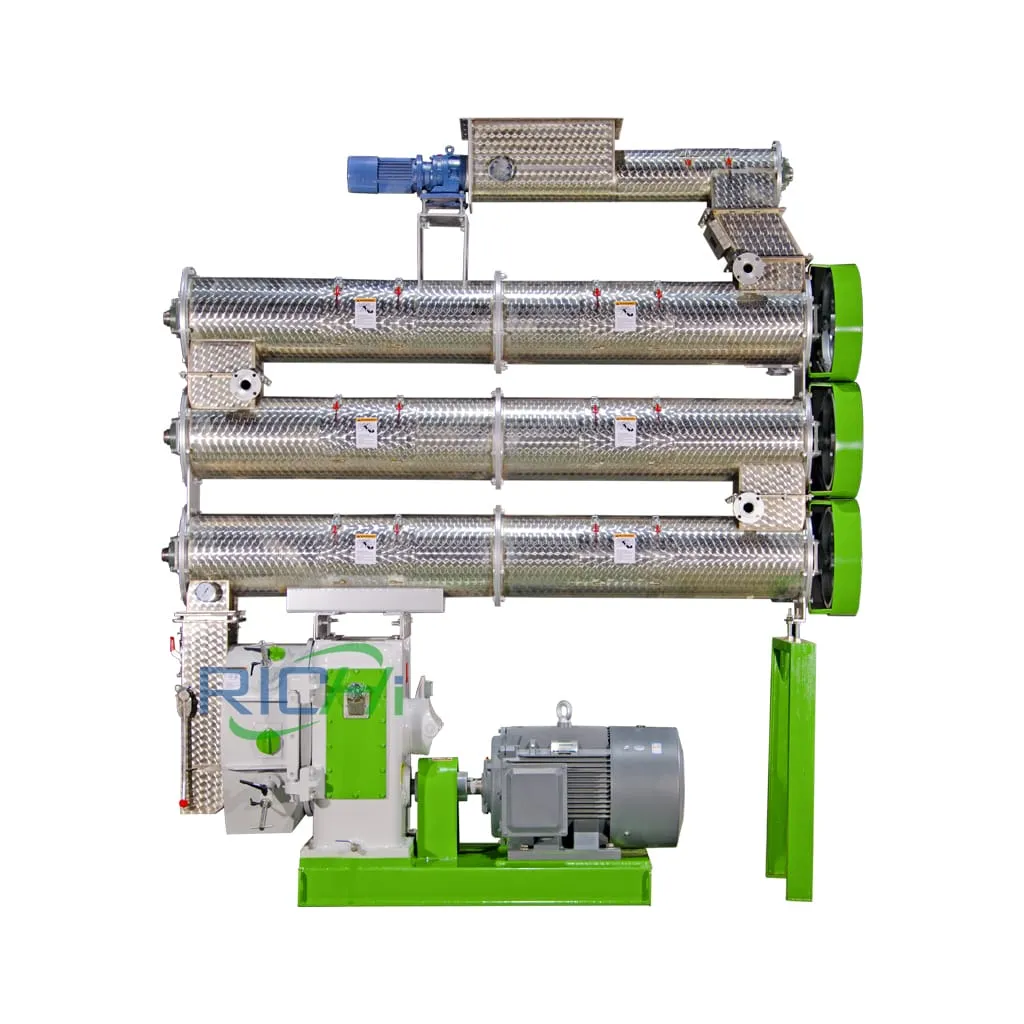

3. Pelleting– SZLH Series Animal Feed Pellet Press

After mixing, it comes to the most critical step—pelleting. Pelleting machine is the key equipment of the feed production line, which directly determines the output of the production line and the quality of the pellets. Therefore, the equipment selection and operation of this step must be emphasized.

4. Cooling– SKLN Series Counter Flow Cooler

The just-made feed pellets temperature and humidity are very high, can not be immediately bagged, easy to cause pellets cracked and easy to go bad. Therefore, it is necessary to utilize the cooling machine to cool the feed pellets to room temperature before packing.

5.Sifting- SCQZ Series Powder Cleaning Machine

After cooling, the mixed material is screened to remove clumps, which ensures the quality of the compound feed.

6. Packing– DCS Series Automatic Packing System

Customers can choose packing method according to their needs. Most customers choose to use automatic packing machine to pack the feed pellets in bags.

If you have definite production requirements, you can leave your contact information and tell us your need, then we will customize a solution for you.

Why Choose RICHI

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Frequently Asked Questions

Customized solutions can help different customers meet their unique business needs, improve efficiency, and reduce costs.

What is the purpose of an animal feed pellet press?

It compresses powdered feed into pellets for easier feeding and reduced waste, meanwhile high temperature sterilization improves feed safety.

What raw materials can be pelleting?

Common raw materials include corn, soybean meal, wheat bran, straw, cottonseed meal, rapeseed meal,sorghum, etc. Premixes such as vitamins and trace elements can also be added. However, it’s important to know that feed formulations vary by animal species and also differ for the same animal at different growth stages. Therefore, we have summarized some common animal feed formulations for your reference.

- Young laying hens (61 to 120 days) feed formula: 55% corn, 20% bran, 7% soybean cake, 5% cottonseed cake, 5% canola cake, 5% fish meal, 2% bone meal, 1% shellfish meal.

- Freshwater shrimp feed formula: Peruvian fish meal 15%, Domestic fish meal 8%, Alcohol mother meal 4%, Soybean phospholipids 4%, Soybean meal 20%, Peanut meal 7.4%, Shrimp over meal 12.5%, Secondary flour 15%, Wheat gluten meal 6%,. Vegetable oil 1.5%, Calcium lactate 0.5%, Calcium dihydrogen phosphate 2.6% , Premix 3.5%

- Cattle feed formula: Corn 60%, soybean cake 10%. Cottonseed cake 20%, bran 5.5%, bone meal 1.5%, salt 1%, baking soda 1%, flavor agent 1%

- Duck feed formula: Corn 60.7%, bran 12.8%, soybean meal 13.2%, cottonseed cake 3.5%, canola cake 3.5%, fish meal 3.5%, stone meal 0.4%, bone meal 1.6%, salt 0.3%, premix 1.0%

- Pig feed formula: corn 56.32%, soybean meal 23.61%, wheat bran 4.78%, premix 10.05%, VE, VC

- Tilapia feed formula: soybean cake 35%, bran 30%, fish meal 15%, barley flour 8.50%, corn flour 5%, acacia leaf meal 5%, bone meal 1%, salt 0.50%.

Does the operation require specialized training?

The equipment features fully automated design. Basic operations can be mastered with just 1-2 days of training, and the touchscreen interface is simple and intuitive.

What maintenance is required daily?

Clean residual material after each workday. Regularly lubricate bearings, inspect molds and rollers for wear.

What is the hourly output? Is the power consumption high?

Depending on the model, small machines (1-2 tons/hour), medium machines (2-5 tons/hour), and large machines (5-10 tons/hour). Power consumption is approximately 15-25 kWh per ton of material.

What is the payback period for investment?

Typically 6-18 months (for small-to-medium models, savings from reduced feed waste and labor costs alone can cover equipment investment).

If you have any other unanswered questions, feel free to contact our technical consultants anytime. We will provide professional solutions!