Organic Fertilizer Pellet Machine

The organic fertilizer pellet machine is a kind of granulator that is used to granulate various organic substances after fermentation. The organic fertilizer pellet making machine can adjust the ring die compression ratio for different requirements of organic fertilizer efficiency, so as to obtain pellets of different hardness. RICHI Machinery specializes in the production of organic fertilizer pellet machine, complete organic fertilizer pellet plants, and other equipment.

- Capacity: 1-12t/h

- The size of finished pellets: 6-12mm

- Raw materials: animal manure, animal and plant residues, slaughterhouse wastes, food residues, fallen leaves, agricultural wastes, etc.

- Application: organic fertilizer plant, organic fertilizer pellet production line, agricultural planting, fruit tree planting, breeding industry, etc.

Various Kinds Of Organic Fertilizer Pellet Machine

MZLH350 Chicken Manure Pellet Machine For Sale

Capacity:

3-4T/h

Main Power:

37KW

MZLH420 Horse Manure Pellet Maker

Capacity:

5-6T/h

Main Power:

90KW

MZLH520 Poultry Manure Pellet Machine

Capacity:

7-8T/h

Main Power:

132KW

MZLH768 Organic Fertilizer Pellet Machine

Capacity:

9-10T/h

Main Power:

250KW

MZLH858 Cassava Residue Pellet Machine

Capacity:

10-12T/h

Main Power:

280KW

The specific parameters of the organic fertilizer pellet machine are as follows:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The Features Of The organic fertilizer pellet making machine

- SKF bearings, Siemens motor.

- The organic fertilizer pellet machine is equipped with the Schneider electric control cabinet.

- The feeder is equipped with an anti-caking device.

- The main transmission adopts high-precision gear rotation, and the efficiency is about 15% higher than the belt transmission.

- Allocated with an overload protection device to extend the working life of the organic fertilizer pellet making machine.

The anti-caking device is avoiding the sawdust from becoming cake so as to keep the wood pellet manufacturing machine working more smoothly.

A variety of diameters of ring die can be provided. And these can be chosen according to different needs, so as to obtain the best technical benefits.

The organic fertilizer pellet machine is equipped with an overloading protection device to increase the service life of the device.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The Main Equipment Of The Organic Fertilizer Production line – An Organic Fertilizer Pellet Machine

The organic fertilizer pellet machine is the equipment used for pressing the powered animal manures, plant residue, and food residue into 6-12mm organic fertilizer pellets. It can not only be used alone but also can be applied in small, medium and large-sized organic fertilizer pellet plant and any scale of organic fertilizer pellets production enterprises.

Making organic fertilizer pellets through the organic fertilizer production line, on the one hand, can provide the nutrients needed for crop growth to improve crop quality and crop yield. On the other hand, it can improve soil physical and chemical performance and promote soil ecosystem circulation.

What’s more, the complete set of equipment for the organic fertilizer pellet plant is not a fixed mode, and it can be customized according to different customers’ needs. The capacity of the organic fertilizer pellet plant is 1-60t/h. The organic fertilizer pellet plant can be customized to your various needs.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

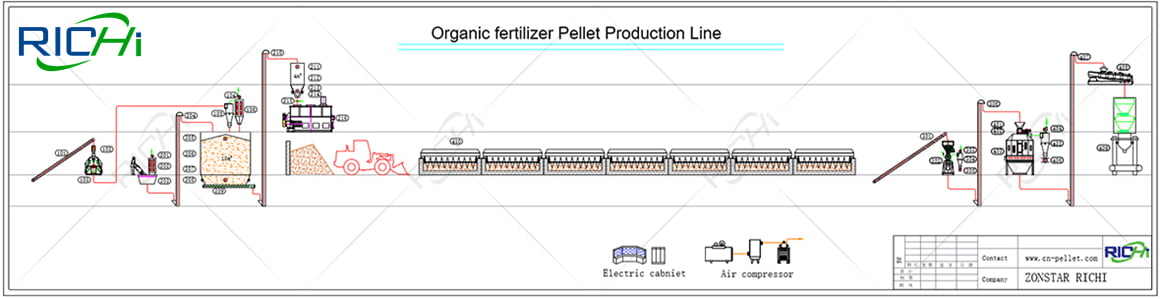

RICHI Whole Organic Fertilizer Production line Working Principle

The organic fertilizer production line is commonly used to make various organic substances into organic fertilizer. RICHI Machinery can provide organic fertilizer pellet plant with various designs. A complete organic fertilizer pellet plant contains dewatering, fermentation, crushing, mixing, pelletizing, cooling, screening and packing.

Dewatering Composting And Fermentation Section

Due to the high moisture content of the animal manures, the first step of the organic fertilizer pellet plant is dewatering. Otherwise, the high moisture content would block the following equipment. Some materials are dry and some are wet, which affects the quality of fermentation. The moisture content in 50-60% is better.

The production of any qualified and high-quality organic fertilizer must go through the process of composting and fermentation. Composting is a process in which organic matter is continuously degraded and stabilized under certain conditions through the action of microorganisms, and a product suitable for land use is produced.

The composting process is mainly carried out based on the action of microorganisms, which are the main body of composting fermentation. There are two sources of microorganisms involved in composting. One is a large number of organic microorganisms in organic wastes. The other is an artificially added microbial inoculum. After mixing the cultures with the fermentation raw materials, the pilers are used during the fermentation process.

What’s more, this section is usually equipped with a turning machine. According to the actual production needs, the turning machine plays a role in uniform fermentation, oxygenation, and cooling, until the materials are thoroughly decomposed.

Crushing Section

After fermentation and storage for a period of time, it should be crushed for convenience for the following pelletizing section. But there is no need of crushing if the compost material is fine enough.

Mixing Section

According to the different crops, nutrients and some minerals can be added so that the organic fertilizer contains the nutrients beneficial for the growth of plants.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Pelletizing Section

The raw material enters the organic fertilizer pellet machine, adding appropriate steam, and it is pressed into pellets. Pelletizing is a vital process of the organic fertilizer pellet plant. The annular mold design of the RICHI organic fertilizer pellet machine has different compression ratios. Annular molds with multiple compression ratios enable the organic fertilizer pellet making machine to process a variety of organic substances.

Cooling And Screening Section

After pelletizing, the temperature of the pellets out of the organic fertilizer pellet making machine is about 80℃. The cooling system is cooling the pellets to about room temperature through the indoor air. Also, the cooled pellets are harder and not easy to break.

The screening process is to select the unqualified pellets to go for secondary granulation through a certain diameter screen. The rotary screener is a high-efficiency material classification and screening equipment widely used in grain, feed, flour, chemical industry, food and other industries.

Packing Section

The packing system is the last process of the whole organic fertilizer pellet plant. The packing system is fully automatic design, more convenient for operation and use. It is good equipment to save manpower and reduce transportation costs.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The Cases Of The Organic Fertilizer Pellet Machine

RICHI Machinery has clients from more than 100 countries and regions all over the world, such as Europe, Asia, Oceania, North America, South America, the Middle East, and Africa. In these regions, we have undertaken the organic fertilizer pellet making machine and organic fertilizer pellet plant. Also, we have technicians to provide clients with professional guidance and maintenance recommendations.

1-2T/H Organic Fertilizer pellet making Machine

Thailand Organic Fertilizer Pellet Machine In The Organic Fertilizer Pellet Plant

Organic Fertilizer Pellet making machine For Production Line Project

15T/H Organic Fertilizer Pellet Machine In The Organic Fertilizer Pellet Plant

Why Use an organic fertilizer pellet making machine?

Agriculture is the foundation of a country and plays a very important role in economic construction. In the past, agricultural planting mainly relied on traditional fertilizers, which not only had a low curative effect but also easily polluted the soil. With the continuous development of the global economy, organic fertilizer began to appear and flourish. Why choose an organic fertilizer pellet machine for processing organic fertilizer? What are the benefits?

The organic fertilizer pellet machine is selected as an ideal product by the majority of users because of its high granulation rate, stable operation, strong and durable equipment, and long service life. The organic fertilizer pellet making machine shell is made of thick seamless steel pipe, which is durable and does not deform.

In addition, the pellets produced by the organic fertilizer pellet machine have the following benefits.

- Organic fertilizer contains a large amount of organic matter, which has an obvious effect on soil improvement and fertilization.

- The organic fertilizer contains a variety of nutrients, which are fully balanced.

- Organic fertilizer has a longer fertilizer effect time.

- Organic fertilizer comes from nature, and there is no chemical synthetic substance in the fertilizer. The long-term application can improve the quality of agricultural products.

- In the process of production, as long as the organic fertilizer is fully decomposed, it can improve the drought resistance, disease resistance, and insect resistance of crops.

- The organic fertilizer contains a large number of beneficial microorganisms, which can promote the bio-transformation process in the soil, and is conducive to the continuous improvement of soil fertility.

The pellets produced by the ring die organic fertilizer pellet making machine has higher hardness, and the relative fertilizer efficiency cycle is longer after fertilization. So using the organic fertilizer pellet machine is necessary.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Why Choose RICHI Machinery?

RICHI Machinery owns CE/ISO/BV certifications. RICHI Machinery has its own factory and professional production equipment. It is an industrial group that mainly focuses on organic fertilizer pellet machine, animal feed pellet machinery, biomass pellet machinery, wood pellet machinery, etc. RICHI pellet machine is sold in many countries and regions in the world. We also provide various solutions for clients based on their different raw materials, production capacity, the kinds of pellets, etc.

RICHI Machinery also provides one-stop service. It has a professional system from structural design, equipment production, and installation to after-sales service.

Feed machinery structural design and equipment production

With more than 20 years of experience in the pellets equipment industry, RICHI Machinery can offer you a professional technical recommendation in building an organic fertilizer pellet plant. On the basis of site surveys for customers, we can provide clients with a detailed project design scheme, design site foundation drawings, and so on.

Feed machinery installation and training

RICHI Machinery has a complete technology training and guiding system. Our technical workers can provide you with free training about how to operate the equipment, and how to do basic maintenance and protection of the equipment.

After-sales service

RICHI Machinery always concentrates on the production of pellet production equipment. And we have a professional and highly-skilled after-sales service team and a modern and information-based after-sales management system. From the supply of common accessories, and equipment maintenance to repair, we provide customers with a one-stop service to release them out of trouble.

RICHI Machinery, as an organic fertilizer pellet machine and organic fertilizer pellet plant manufacturer, would offer you all-around service. If you want to learn more about the equipment, just contact us directly and we are always here for you.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

FAQ of organic fertilizer pellet machine

How To Choose The Right Chicken Manure Pellet Making Machine?

Chicken manure is a good raw material for organic fertilizer. It is necessary to get corresponding equipment to produce organic fertilizer with chicken manure. So how can we choose a better organic fertilizer pellet machine manufacturer? This is a confusing question for many newcomers. As a large manufacturer of organic fertilizer equipment, RICHI Machinery will help you.

First of all, it depends on the production strength of the manufacturer. Organic fertilizer equipment is usually large in size and relatively expensive. The manufacturing cost and related research and development expenses are also relatively high, which cannot be realized by manufacturers without strength.

Secondly, look at the manufacturer’s production technology. The machining industry takes precision as its priority, which requires not only skilled operators but also advanced and perfect parts processing equipment.

What’s more, look at the manufacturer’s sales model. Regular large manufacturers generally adopt the factory direct selling mode. The phenomenon of hard promotion by small manufacturers occasionally appears in the market to confuse consumers.

Last, it depends on the technical level of the manufacturer and the corresponding after-sales service system. An experienced organic fertilizer equipment manufacturer will play a very important role in the process of building your factory and avoiding detours.

RICHI Machinery, with more than 20 years of experience, owns its factory and professional technical team. RICHI specializes in organic fertilizer pellet plant equipment, animal feed pellet production equipment, and biomass pellet production equipment. We can supply you with all-around service, from testing to delivery, installation, and training to after-sales service. RICHI can help you a lot in equipment selection and production technology. Welcome to inquire us!

Why Is Organic Fertilizer Production Equipment Very Important For Green Agriculture?

Agriculture is the foundation of a country and plays a very important role in economic construction. In the past, agricultural planting mainly relied on traditional fertilizers, which not only had a low curative effect but also easily polluted the soil. With the continuous development of the global economy, organic fertilizer began to appear and flourish. Many people began to use organic fertilizer in agricultural planting when they saw the use of organic fertilizer.

Organic fertilizer, commonly known as farmyard manure, comes from a wide range of sources, including various animal and plant residues or metabolites, such as human and animal manure, straw, animal residues, slaughterhouse waste, etc. It mainly uses the supply of organic matter as a means to improve the physical and chemical properties of soil and promote plant growth and the circulation of the soil ecosystem. Organic fertilizer can not only provide nutrients for crop growth and improve soil but also improve crop quality and yield.

The extensive use of chemical fertilizer has made the soil’s microecological environment relatively poor, and the return rate of chemical fertilizer has also been declining. Therefore, developing the organic fertilizer industry is an ideal means to improve the crop planting environment. The proportion of organic fertilizer used in developed countries is between 50-60%. The development of organic fertilizer is not only the need to improve food quality but also the need for sustainable agricultural development.

The following are several advantages of organic fertilizer application in crops summarized by RICHI Machinery.

Supply crops with nutrients and active substances

The organic fertilizer produced by the organic fertilizer pellet machine can supply crops with nutrients and active substances to improve the intensity of photosynthesis. During the continuous mineralization of soil, an organic fertilizer starter can continuously supply crops with various essential nutrients for a long time, and also provide a variety of active substances, such as amino acids, RNA, humic acid, and various enzymes.

Promote the increase in crop yield and income

Comprehensive nutrition promotes an increase in crop yield and income. Livestock manure organic fertilizer is rich in organic matter, which can provide crops with nitrogen, phosphorus, potassium, and other trace elements, greatly improve the quality of agricultural products, melon vegetables, and rice flavor, and can effectively improve soil physical and chemical properties, loosen the soil, enhance soil permeability, and greatly improve soil fertility. Bio-organic fertilizer consists of nitrogen-fixing bacteria, phosphorus-releasing bacteria, and potassium-releasing bacteria. After application, the nutrients in the soil can be transformed into crops and continue to provide nutrients to crops.

Improve soil fertility

Improving soil fertility is one of the main indicators to measure the level of soil fertility, the material basis of soil fertility, and the material source to supplement and renew soil organic matter. When applying organic fertilizer, it can continuously supplement the consumed organic fertilizer. Depending on chemical fertilizer alone, the soil structure will be destroyed and consolidated in a few years. Also, it can increase the content of soil organic matter. What’s more, the continuous renewal of soil organic matter. The transformation of organic fertilizer into soil organic matter accounts for about 2/3 of the annual formation of soil organic matter. It can be seen that in order to continuously renew soil organic matter, organic fertilizer must be supplemented. Obviously, it is very important to apply organic fertilizer to improve soil fertility.

The above are the advantages of organic fertilizer summarized by RICHI Machinery, and it is also that organic fertilizer can effectively improve crop yield. Compared with the quality and price of traditional fertilizer, it is deeply loved by agricultural workers. Thus, organic fertilizer production equipment is very important for green agriculture. If you are interested, just contact us.

Why Should We Reduce The Use Of Chemical Fertilizers And Adopts Organic Fertilizer Production Lines?

With the development of the global economy, environmental protection has attracted people’s attention. At present, many people use organic fertilizer pellet machine to produce organic fertilizer to replace chemical fertilizer. So what are the advantages of the organic fertilizer produced by the organic fertilizer pellet making machine?

- Organic fertilizer contains a large amount of organic matter, which has an obvious effect on soil improvement and fertilization. Chemical fertilizers can only provide inorganic nutrients for crops, and long-term application will cause adverse effects on the soil, making the soil “more greedy the more it is planted”.

- Organic fertilizer contains a variety of nutrients, which are fully balanced. However, fertilizer contains a single variety of nutrients, and long-term application is easy to cause a nutrient imbalance in soil and food.

- The organic fertilizer has a longer fertilizer effect time. While chemical fertilizer has a short and fierce fertilizer effect period, which is easy causes nutrient loss and environmental pollution.

- Organic fertilizer comes from nature, and there is no chemical synthetic substance in the fertilizer. Long-term applications can improve the quality of agricultural products. Chemical fertilizer is a kind of pure synthetic material. Improper application can reduce the quality of agricultural products.

- In the process of production and processing, as long as the organic fertilizer is fully decomposed, it can improve the drought resistance, disease resistance, and insect resistance of crops and reduce the use of pesticides. The long-term application of chemical fertilizers often requires a large number of chemical pesticides to maintain crop growth due to the reduction of plant immunity, which is easy to cause the increase of harmful substances in food.

- Organic fertilizer contains a large number of beneficial microorganisms, which can promote the biotransformation process in the soil, and is conducive to the continuous improvement of soil fertility. Long-term application of chemical fertilizers can inhibit the activities of soil microorganisms, resulting in the decline of soil self-regulation ability.

So organic fertilizer pellet plant is suitable for the planting industry. RICHI Machinery, as an organic fertilizer pellet plant manufacturer, always regards product quality as the life of the enterprise. We provide various organic fertilizer pellet manufacturing equipment for customers according to various needs, raw materials, production capacity, etc. If you are interested in an organic fertilizer pellet machine, just send an inquiry to us.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production