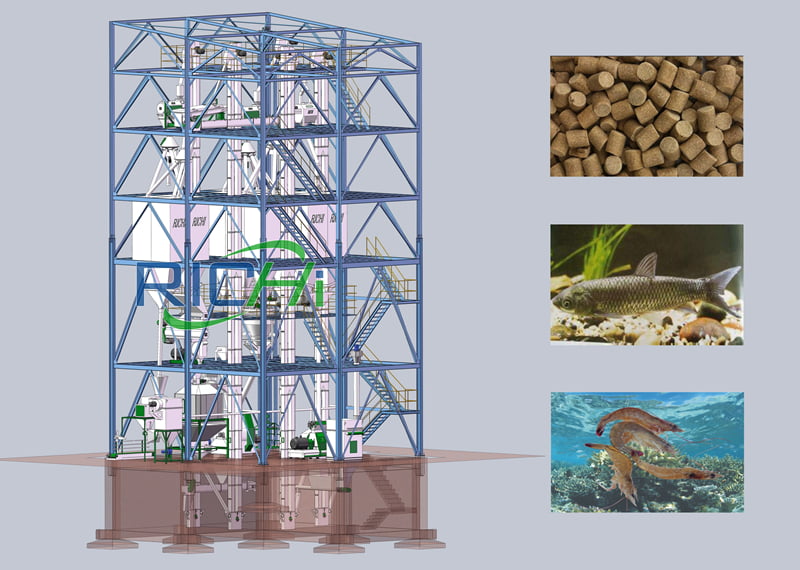

Floating fish feed plant in Iran

The floating fish feed plant is a turn-key project for Iran client contracted by RICHI Machinery. This is a compound 1.5-2T/H extruding fish feed production line and a 5-6T/H animal feed production line. It is mainly used to produce fish feed pellets and shrimp feed pellets.

- Capacity: 1.5-2t/h floating fish feed and 5-6t/h shrimp feed

- Feed pellet size: 1-12mm

- The installed period: 90 days

- The operating worker: 4-5 person

Iran aquatic feed pellet production market

Iran is close to the Caspian Sea to the north, the Persian Gulf, and the Arabian Sea to the south. In 2019, seafood accounts for nearly 10% of Iran’s annual agricultural exports. In 2021, Iran’s aquatic products exports have increased by 12%. What’s more, Iran treats supporting aquaculture as a fundamental state policy. In 2021, Iran’s seafood exports increased by 280% compared to the same season last year. So the Iran client grasps the opportunity, investing in a floating fish feed plant. How does a fish feed processing line work and what equipment is needed in the plant? Just as the video shows.

The Iran client of the fish feed processing line

Iran client runs a multinational business that can provide high-quality food and drinks as well as a variety of other van mei shrimp, sea shrimp, jellyfish, anchovy, cuttlefish, and eel. The company has been engaged in fish farming for more than 15 years, mainly exporting to Australia, Canada, Germany, Italy, England, China, etc. What’s more, it has established partnerships with many countries and is one of Iran’s best exporters.

On May 19th, 2022, Iran’s client signed a contract with RICHI Machinery for a compound 1.5-2T/H extruding fish feed processing line and a 5-6T/H animal feed production line. The entire floating fish feed plant was completed by RICHI Machinery from design, and feed equipment manufacturing to feed factory erection and commissioning. In this project, RICHI always adheres to the concept of product quality at first. RICHI strictly checks all aspects of the project construction and ensures this project can proceed orderly and efficiently.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The main equipment of the fish feed production line in Iran

Iran’s floating fish feed plant can adjust the raw materials, temperature, moisture, and other process parameters, so that the product has the characteristics of novel shape, unique taste, rich nutrition, etc., suitable for the taste of different animals.

The compound fish feed pellet production line is equipped with feed grinder machine, feed mixer machine, feed pellet machine, twin screw fish feed extruder, screening system, etc. The following is the specific equipment of the whole floating fish feed pellet plant.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The animal feed production process

Since customers use this production line to produce fish feed, they will also produce some other animal feed, and RICHI Machinery has designed a composite floating fish feed plant for the client. The fish feed production line is equipped with a feed pellet making machine and a twin screw fish feed extruder. Customers can use either device according to their needs. The following is the detailed fish feed processing line for Iran’s client.

Raw materials receiving and cleaning system

The cleaning is to remove paper, rope, clods, and iron filings in the raw material, so as to protect the equipment from damage.

Crushing system

The feeder controlled by frequency conversion speed regulation can flexibly adjust the working load of the crusher to the best to ensure the full load production of the crusher.

Batching and mixing system

The computer can control the batching and mixing section. You just need to input a few formulas into the computer. As long as the corresponding formula is selected, the computer can automatically control the unloading amount of each bin.

Pelletizing and extruding system

This is a compound production line. It is equipped with a feed pellet making machine and a twin screw fish feed extruder in the pelletizing system. The feed pellet making machine with a three-layer conditioner is used to produce shrimp feed pellets and other animal feed pellets. And the twin screw fish feed extruder is mainly used to make floating fish feed pellets.

Cooling and screening system

The cooling machine designed by RICHI Machinery has the characteristics of high output, good classification, low noise, and vibration.

Packing system

The automatic packing scale is a professional quantitative weighing and packaging equipment. Also, it can save time and labor.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The design highlights of the Iran project

When we communicated with our client about the design proposal, we also encountered some problems. But in front of our professional technical team, everything is not a problem.

01 The limited height of the client’s factory

The height of the client’s factory is only 6m, and it cannot break the roof. RICHI technicians used a crimping conveyor instead of a wind transport system to successfully control the overall height of the production line below 6m.

02 A compound floating fish feed and shrimp feed pellet production line

The Iran client wants to produce floating fish feed pellets and shrimp feed pellets. So in the pelletizing process, our technicians design the plant equipped with a feed pellet making machine and a twin screw fish feed extruder. This meets the needs of the Iran client.

03 The drying system

After extruding, the floating fish feed plant is equipped with a belt drying machine. The drying process is to reduce the moisture of the material to about 10-11% so that it can reduce the break up of the pellets.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The installation and layout of the fish feed production line in Iran

After the production of the equipment, we contacted the customer for the first time and carried out the trial operation of the equipment. The customer is very satisfied with this, not only for the production capacity of the floating fish feed pellet plant but also for the service of RICHI.

The installation of the whole floating fish feed plant lasts 90 days, and our technical engineers help with the equipment installation successfully online. Moreover, RICHI also provides online training for Iran clients.

The relative location of the raw material warehouse, production workshop, and finished product warehouse is reasonable. The raw materials workshop is located next to the feed production workshop, so the efficiency of receiving raw materials and the finished product delivery is improved, and the logistics cost and loading and unloading costs will be reduced. The floor area and height of the production workshop are reasonably designed, and the investment in buildings and equipment of the enterprise will be reduced, and the operating cost of the equipment will be reduced.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The safety production of the floating fish feed plant in Iran

Safe operation

The floating fish feed pellet plant is equipped with a safety interlock device to protect personal safety. This avoids the problem of personal safety accidents caused by workers’ operational errors.

Dust explosion

A large amount of dust may be generated during feed production. But don’t worry. The Iran floating fish feed pellet plant is equipped with a pulse dust removal system with a dust collection efficiency of up to 99%.

Electrical safety

The electrical control cabinets provided for the floating fish feed plant all meet the requirements of relevant national standards.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The effect on the environment of the project and the solutions provided by RICHI Machinery

The atmospheric pollutants emitted by this project are mainly dust, and the pollution factors are carbon dioxide and TSP, all of which are conventional pollutants, which meet the emission standards and have low pollutant emission concentrations.

The floating fish feed plant is equipped with low-noise equipment. Also, the clients take some measures of sound insulation, and shock absorption to deal with the noise. The noise will not affect the environment after treatment.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The best pellet equipment manufacturer – RICHI Machinery

With 27 years of experience, RICHI provides Iran client with a full range of turnkey services, including flow chart, quotation, stocking list, steel structure list, wires, and cables list, factory layout, installation diagram, shipment, installation, training, and after-sales services.

Complete Iran floating fish feed plant equipment provided by RICHI Machinery have many advantages, attracting customers from Nigeria, Bolivia, Uzbekistan, Ecuador, Nigeria, Botswana, United Kingdom, Ukraine, Cote d’Ivoire, and other countries. For any questions about the cost of equipment for the floating fish feed plant in Iran, please contact RICHI Machinery. Just tell us your requirements, and we will offer you the best service.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production