Animal Feed Production Line

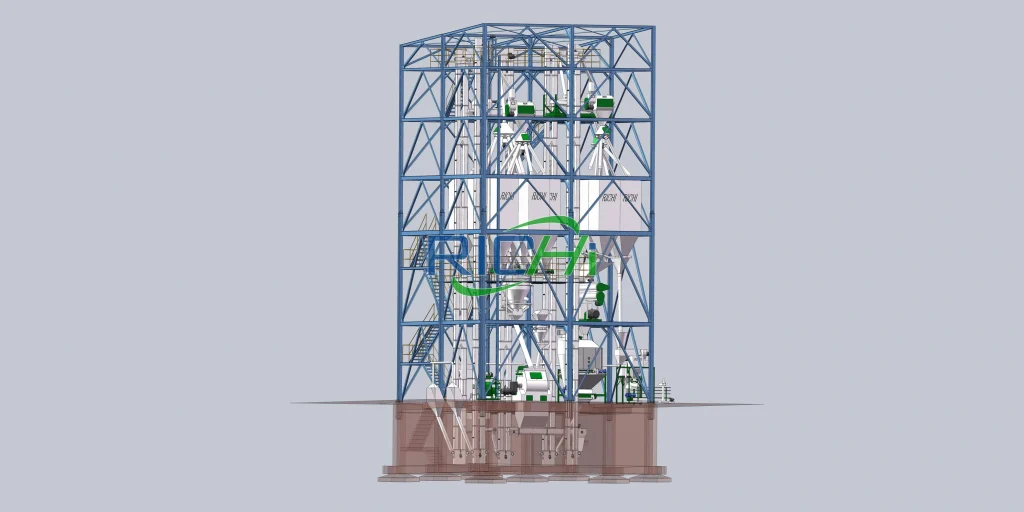

RICHI animal feed production line is a complete set of equipment that processes various powdered raw materials (such as grains, soybean meal, minerals, etc.) into high-quality pellet feed through multiple stages, which is widely used in the animal husbandry industry (poultry, livestock, aquaculture, ruminants) to achieve automated and large-scale feed production.

General Introduction For Feed Production Line

RICHI tailor-made feed production solutions make the difference for the feed

Over the past 30 years, we have constructed over 1,000 large and small pellet mill projects worldwide. Its essence lies in the synergistic processing of machinery operation across various production stages and the precise nutritional formulation of raw materials. This converts loose, dusty, and unpalatable ingredients into dense, easily stored, digestible, and nutritionally balanced pellet feed. Meanwhile, high temperature and pressure can eliminate certain harmful microorganisms in raw materials, which improves feed safety. Fully automated production from ingredient feeding to finished product packaging helps farmers increase feed utilization and reduce farming costs.

Animal feed production lines are based on the physiological characteristics, nutritional requirements, and feeding scenarios of different farmed animals. Different animal categories exhibit significant variations in their demands for pellet hardness, particle size, and nutritional ratios. We will customize feed pellet production lines for you to manufacture suitable feed pellets, ultimately covering mainstream farming sectors such as poultry, livestock, aquaculture, and ruminants. Simultaneously, we extend our reach to specialty farming and emerging agricultural applications, and promote the standardized and efficient development of modern animal husbandry.

RICHI MACHINERY

animal feed production line video

The animal feed factory project is a complete set of machinery that processes raw materials such as corn, soybean meal, and straw into standardized pellet feed through a series of continuous operations including grinding, mixing, tempering, pelleting, cooling, and screening. It is suitable for all types of farmed animals.

RICHI MACHINERY

feed Production Line Process

There are various kinds of feed pellet lines various from the production process, output, configuration, etc. Next, I will take the general animal feed production line process as an example to explain to you.

1.Cleaning

The initial cleaning of powdered raw materials separates agglomerates, straw, hemp rope, paper scraps, stones, and other large impurities mixed within the powdered material to ensure the normal operation of subsequent equipment.

2.Crushing

It is necessary to crush the food materials which are prepared according to the formula. This not only can ensure the pelleting effect of the pellet machine, but also can make the raw materials easier to digest and absorb by the animals.

3.Mixing

After crushing, we need a feed mixer to mix the crushed raw materials evenly. It can make the made feed pellets nutritionally balanced, and promote the healthy growth of animals.

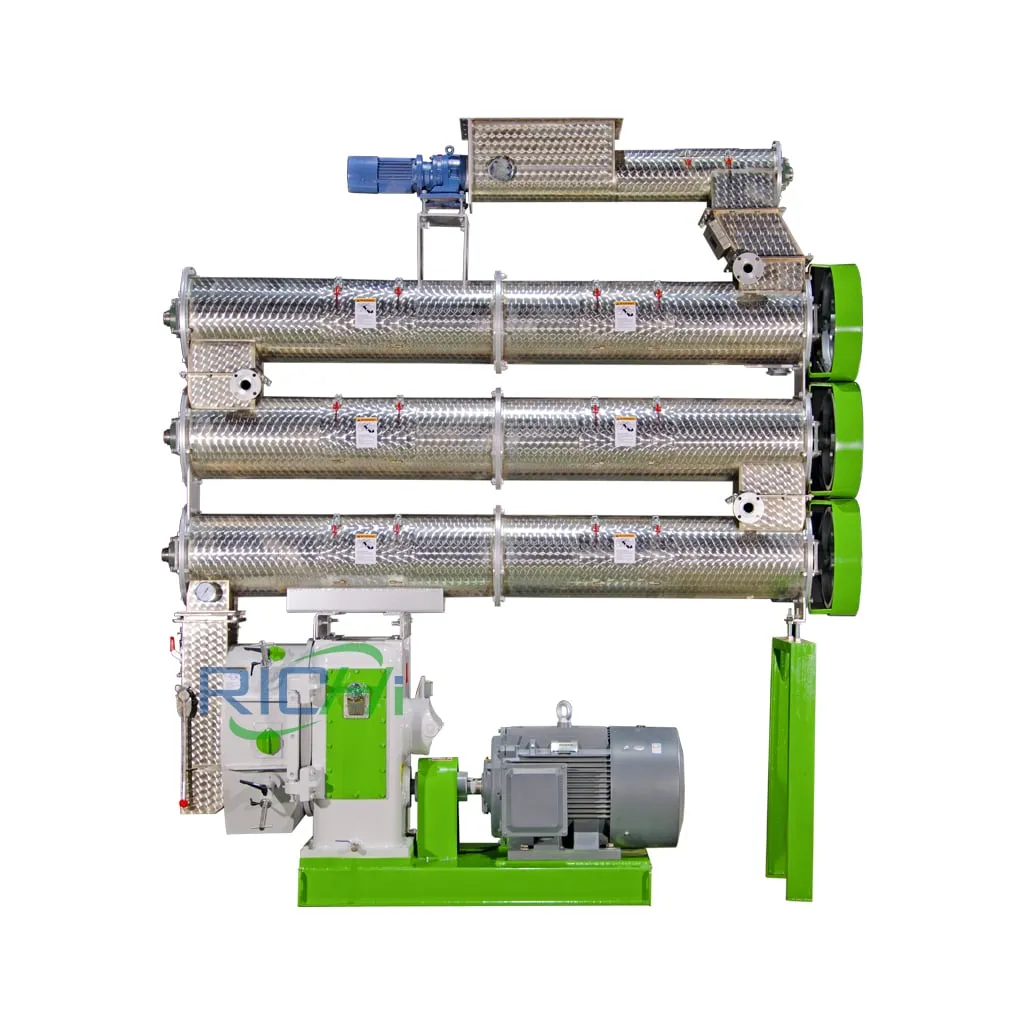

4. Pelleting

After mixing, it comes to the most critical step—pelleting. Pelleting machine is the key equipment of the animal feed production line, which directly determines the output of the feed pellet line and the quality of the pellets. Therefore, the equipment selection and operation of this step must be emphasized.

5. Cooling

The just-made feed pellets temperature and humidity are very high, can not be immediately bagged, easy to cause pellets cracked and easy to go bad. Therefore, it is necessary to utilize the cooling machine to cool the feed pellets to room temperature before packing.

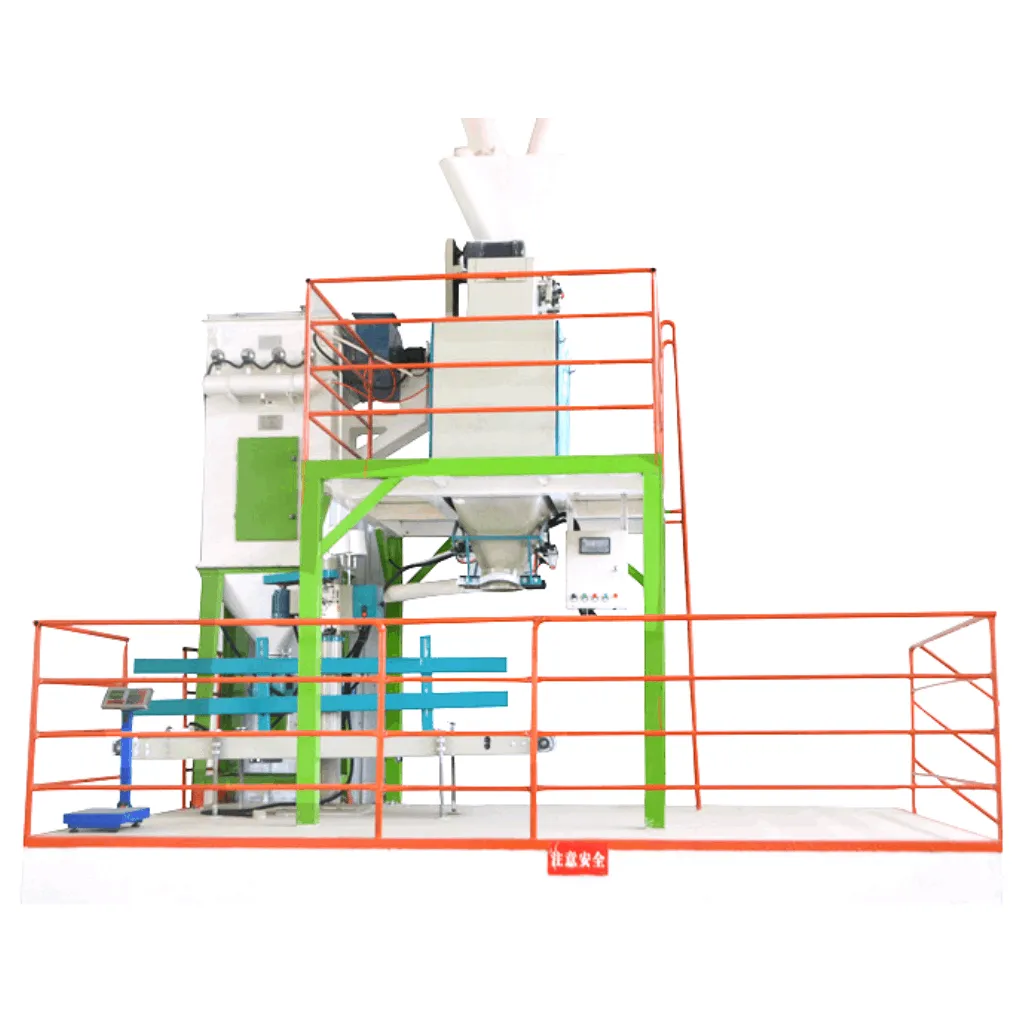

6.Sifting and Packing

After cooling, the mixed material is screened to remove clumps, which ensures the quality of the compound feed. Customers can choose packing method according to their needs. Most customers choose to use automatic packing machine to pack the feed pellets in bags.

MAIN EQUIPMENT IN ANIMAL FEED PRODUCTION LINE

Next, let’s explore the core components of RICHI Machinery’s main animal feed production line equipment.

Powder Cleaning Machine

RICHI SCQZ series powder cleaning machine is mainly used for the initial cleaning of powder raw materials in feed mils, which can effectively crush the agglomerates in the powder raw materials, separate the straw mixed ,Hemp rope, paper pieces, stones, etc. in the powder raw materials, which ensures the normal operation of subsequent equipment. The machine can also be used for sifting the mixed materials, clearing the clumps, and ensuring the quality of compound feed.

Water-drop Hammer Mill

RICHI SFSP Series Water-drop Hammer Mill is used by large and medium-sized livestock, poultry and aquatic feed enterprises to crush raw material. It is also suitable for fine crushing in the pharmaceutical industry. It can crush all kinds of granular materials, such as corn, sorghum, wheat, beans, crushed cake and other materials. This high efficiency hammer mill is more suitable for fine crushing of raw materials.

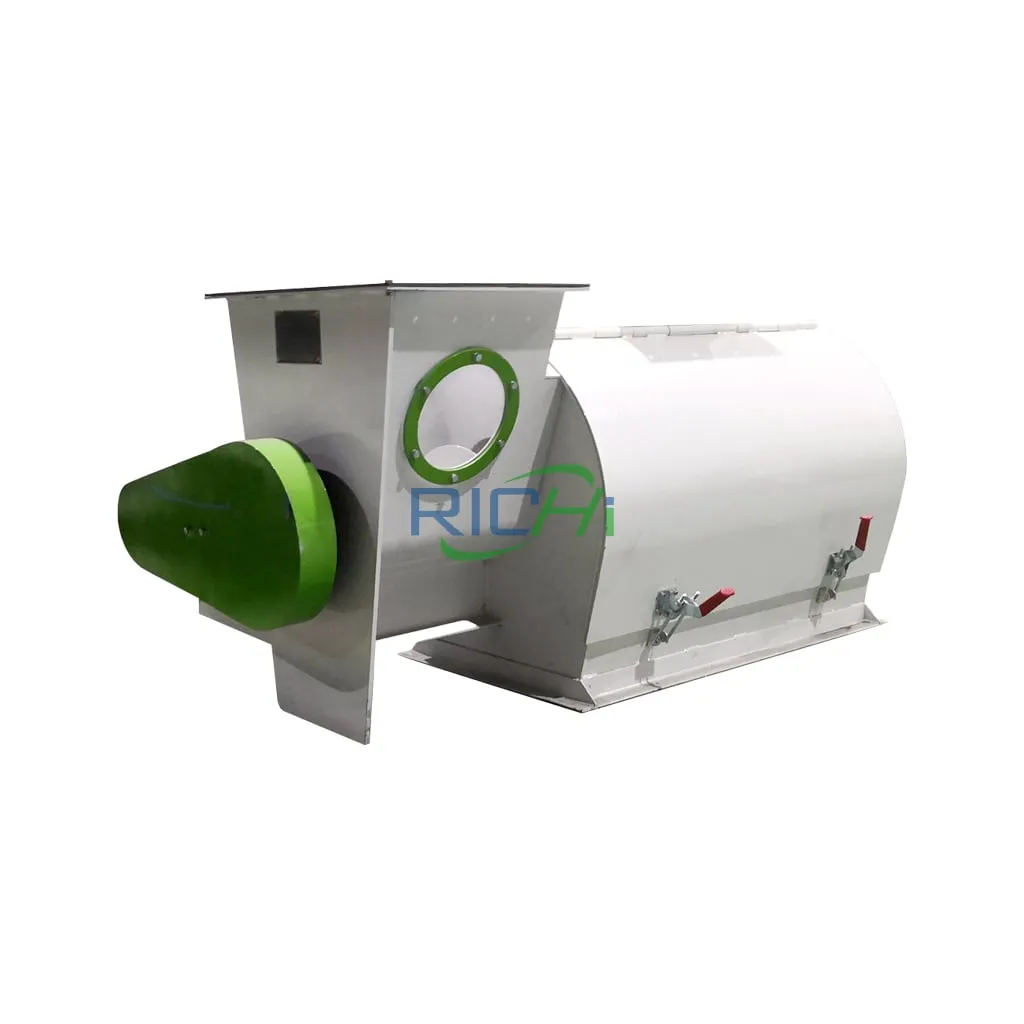

Feed Pellet Mixer

RICHI SLHY series feed pellet mixer widely used in small and medium-sized feed mils. It is used to mix powdered materials to make the components of the mixture evenly distributed and ensure the quality of compound feed.

Feed Pellet Machine

RICHI Machinery SZLH series feed pellet machine is mainly suitable for the production of animal feed pellets livestock, poultry, rumination, aquatics.

Grass Feed Pellet Machine

RICHI Machinery SZLH Series Grass Pellet Machine is mainly suitable for the production of ruminant feed pellets with various grass powders and raw grains such as forage, alfalfa, straw, hemp, hops and so on.

Shrimp Feed Pellet Machine

RICHI SZLH series shrimp feed pellet machine is mainly suitable for the production of shrimp feed pellets. According to the characteristics of shrimp material to design the speed of the ring die, which greatly improve the production capacity of the pellet machine and the appearance and internal quality of the shrimp pellet.

Counter-flow Cooler

RICHI SKLN Series Counter-flow Cooler employs a counter-flow cooling principle to ensure sufficient and uniform cooling of particles. It adopts a unique slide valve discharge mechanism for smooth and reliable operation with consistent material flow. The temperature of the cooled pellets does not exceed room temperature by more than 3–5°C.

Automatic Packing System

RICHI DCS Series Automatic Packing System is suitable for quantitative weighing on packing pellets and powder materials. It is a professional quantitative weighing and packaging equipment. This machine has fast packaging speed, high efficiency, stable and reliable operation, which is easy to operate.

different ANIMAL PELLET PRODUCTION LINES PRICE

RICHI can design the animal feed production lines with different production capacities for various animals. We provide practical solutions based on customers’ raw materials, production requirements, pellet size specifications, plant scale, and budget. Below are the production capacities of animal feed production lines we have designed for your reference.

chicken feed pellet production line

- Raw materials: Soybeans, corn, wheat, other grains, etc.

- Chicken types: Broilers, breeding chickens, laying hens, bantams, etc.

- Type: Manual batching, PLC batching

- Pellet size: 1.5-4mm for chickens

- Capacity: 1-2T/H

- Price: $30,000-$60,000

cattle feed pellet production line

- Raw materials: Corn, soybean meal, cottonseed meal, bran, bone meal, etc.

- Cattle types: Dairy cows, beef cattle, water buffalo, etc.

- Type: Manual Batching, PLC Batching, Fully Automatic Batching

- Pellet Size: 4-6mm for cattle

- Capacity: 5-6T/H

- Price: $80,000-$250,000

fish feed production line

- Raw materials: Bran, fish meal, barley flour, corn flour, bone meal, etc.

- Fish species: Grass carp, crucian carp, common carp, tilapia, sea bass, etc.

- Type: PLC Batching, Fully Automatic Batching

- Pellet Size: Typically 1-5mm for fish

- Capacity: 10T/H

- Price: $170,000–$320,000

Advantages of Animal Feed Production Lines

Feed pellet production lines not only improve feed quality but also deliver significant benefits to the livestock industry. Below are their primary advantages.

Improve Feed Utilization

Through high-temperature and high-pressure processing, starch in feed becomes matured, which makes it easier for animals to digest and absorb. This improves feed conversion efficiency by 15%-20%, which directly reduces feed costs.

Sterilization and Disinfection

High-temperature processing can effectively kill harmful microorganisms, which reduces the incidence of animal diseases and improves breeding survival rates.

Convenient Storage and Transportation

Loose and scattered raw materials are compressed into compact and uniform pellets. This not only saves storage space but also prevents moisture absorption and extends shelf life. Transportation is also more convenient, and the pellets are not easy to spill.

High Degree of Automation

The entire process from raw material handling to finished product packaging is fully automated, which only requires 1-2 operators. This greatly reduces labor costs and enhances productivity.

Flexible and Adjustable Formulations

We provide customized feed formulations according to the specific needs of different animals and growth stages, so that you can flexibly adjust feed recipes and achieve multi-purpose use with a single machine.

Fast Return on Investment

Typically, the investment cost can be recovered within 6-18 months. Each ton of pellet feed generates 20% more profit than powdered feed.

Animal Feed Production Lines Cases

Below are some projects we have done. If you are interested in these animal feed production lines, please contact us for more details.

1-1.5T/H Cattle Feed Production Line in Kenya

- Background: An integrated family farm raising dairy cattle, laying hens, and meat sheep. With the aim of utilizing abundant local resources of corn, soybean meal, and alfalfa to produce self-sufficient feed, which reduces reliance on purchased feed.

- Date: 2024

- Total Power: 90KW

- Price: $70,000-$90,000

2-3T/H Fish Feed Production Line in Vietnam

- Background: An aquaculture feed company in Vietnam’s Mekong Delta region, specializing in the production of high-quality extruded sinking and floating feeds for tilapia fish. These feeds are supplied to large-scale local aquaculture farms.

- Date: 2025

- Total Power: 350kw

- Price:$450,000-550,000

5-6T/H Pig Feed Production Line in Germany

- Background: A modern livestock enterprise in Germany with an annual output of 50,000 hogs. To reduce feed costs and ensure feed quality and safety, the company decided to establish its own feed mill. This initiative not only meets its own needs but also enables contract manufacturing for nearby livestock farmers.

- Date:2023

- Total Power: 280KW

- Price: $180,000-$220,000

What Can RICHI Do For You?

RICHI Machinery is a professional team with over 20 years of experience.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Certificates Obtained

All products have obtained international certifications including ISO, CE, SGS, and BV.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each machine for you.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the machines are finished, we’ll pack them up and work with a professional logistic company to deliver them safely and punctually to your appointed place.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond and will try to resolve it remotely by phone or video.

FAQ About Animal Feed Production Line

1

Is there significant noise and dust during production?

Modern animal feed production lines adopt enclosed and low-noise designs, equipped with pulse dust collectors. Workshop dust concentration can be controlled below 10mg/m³, which meets environmental standards. Noise primarily originates from crushers, but is controlled through soundproof enclosures, with overall noise levels maintained below 85 decibels.

2

How many operators are required?

Labor requirements depend on automation levels. Basic animal feed production lines need 3-5 operators (for operation, feeding, and packaging). Fully automated animal feed production lines require one operator in the central control room plus 1-2 support staff.

3

Why are the final pellets so soft and prone to crumbling?

The failure of feed pellets to form properly is most likely due to the following reasons:

1.Insufficient temper: Poor steam quality (high moisture content, low temperature) prevents starch from fully gelatinizing.

2.Formulation issues: Excessive fiber content, excessive oil or moisture, low protein content.

3.Ring die issues: Insufficient extrusion time due to an excessively short effective die bore length or an overly thin ring die.

4

Why do pellets have high temperature and moisture after cooling?

Possible reasons include:

1.Insufficient cooling time, with material staying too briefly in the cooler.

2.Inadequate airflow, either due to the fan damper not fully open or air duct blockage.

3.Excessively high environmental humidity, where the incoming cooling air itself carries high moisture, impairing cooling efficiency.

We recommend promptly inspecting and adjusting the cooler to ensure sufficient cooling time, typically 15-20 minutes. Regularly clean the air filter and check the fan’s operating status to maintain maximum airflow. In extremely humid environments, you may also consider dehumidifying the cooling air.