Alfalfa Pellet Mill For Sale

The RICHI alfalfa pellet mill for sale is specifically designed to process crushed alfalfa grass into pellets for animal feed and biomass fuel.

Product Overview Of Alfalfa Pellet Mill For Sale

The key equipment for achieving a significant increase in alfalfa’s value

The alfalfa pellet mill for sale is a specialized agricultural machine that processes crushed and dry alfalfa hay into high-density, uniformly sized cylindrical feed pellets through a physical process of high temperature and pressure. This processing method completely resolves numerous challenges related to alfalfa storage, transportation, and feeding.

The pelleting process ensures alfalfa is uniformly blended, which maintains consistent nutritional content in every pellet and significantly improves feed utilization. At the same time, the high temperatures generated during compression can eliminate some pathogens. The final pellets have low moisture content, which makes them less prone to mold growth, thereby extending shelf life and enhancing feeding safety. Alfalfa pellet machines produce pellets with excellent flowability and minimal dust, which are ideal for mechanized and automated feeding systems. This significantly reduces labor costs for modern large-scale farms and enhances livestock production efficiency. In addition, materials such as alfalfa and wood chips can be crushed and compressed into pellets by alfalfa pellet mills. These pellets can be used as fuel, which will not produce sulfur dioxide during combustion and will not cause any pollution, so it is a green energy source.

Working Principle

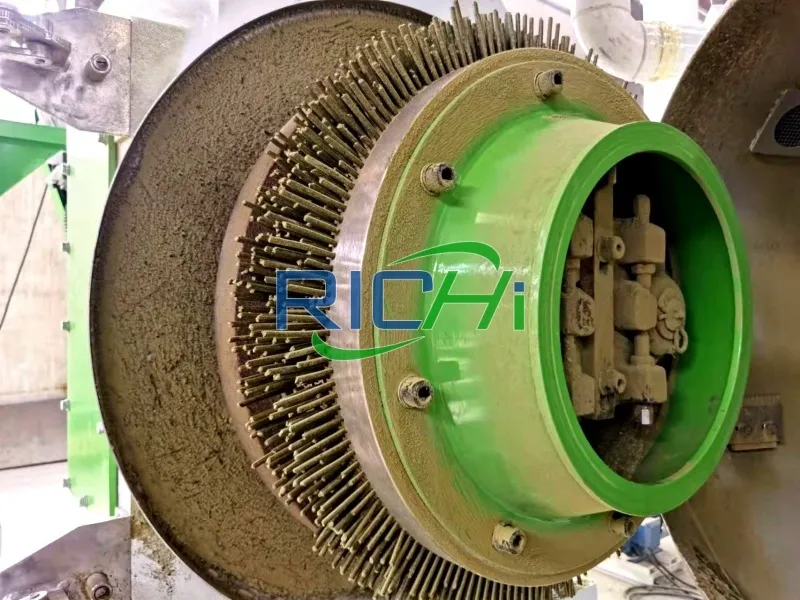

The working principle of the alfalfa pellet mill for sale involves the physical process of compressing loose alfalfa powder through mechanical pressure, friction-generated heat, and the material’s inherent physical changes. This process forces the material through a specific die, which converts it into high-density pellets. The entire process includes four distinct stages.

- Compression: The crushed alfalfa powder is continuously and evenly fed between the ring die and the press rollers. As the main shaft drives the ring die to rotate at high speed, the immense centrifugal force and the material’s own friction cause the press rollers to rotate in the opposite direction. During this process, the material undergoes dramatically increased compression.

- Conditioning: Continuous steam injection generates high temperatures, and intense friction rapidly increases the material’s temperature. This heat softens the lignin in alfalfa meal, which melts at high temperatures and acts as a natural binder.

- Forming: Under immense pressure, the softened and initially bonded material is forcibly extruded through the die holes in the ring die, which forms dense cylindrical strands.

- Cutting: Fixed blades installed externally on the ring die cut the continuously extruded alfalfa strips into pellets of a predetermined length.

Test Run Video And Components Display Video

RICHI Alfalfa pellet mills for sale transform low-value roughage into high-value commodities that are easy to trade and store, which brings significant economic benefits to alfalfa growers.

RICHI MACHINERY

Parameters and Models of Alfalfa Pellet Mills For Sale

RICHI alfalfa pellet mills for sale have various models. Below are the most common models and their specifications. Additionally, we can customize alfalfa pellet making machines to meet individual customer requirements.

RICHI MACHINERY

Core Components

RICHI Machinery’s CZLH Series Alfalfa Pellet Machine for sale is specifically designed for the characteristics of alfalfa grass and can be customized to meet different customer requirements.

- The entire machine’s transmission system utilizes premium SKF bearings, ensuring stable construction and extended service life.

- The main cabinet adopts high-quality cast steel components with uniform thickness and a compact structure, which provides enhanced support for normal operation.

- Equipped with a safety pin that provides overload protection by breaking if the main motor overloads.

- Features a Siemens motor to ensure that the alfalfa pelletizer maintains stable production efficiency over a long period.

- The main drive system utilizes gear transmission for high efficiency, with an output 15% higher than belt-driven models.

Applications of Alfalfa Pellet Mills For Sale

The grass pellet mill successfully integrates alfalfa into three distinct markets of feed, fuel and fertilizer, which realizes comprehensive resource utilization from energy to ecology and significantly expands the value of alfalfa.

Application in Large-Scale Livestock Farms

The fluffy alfalfa hay is compressed into high-density pellets, which perfectly solves transportation and storage challenges and achieves standardized nutritional feeding.

- Dairy Cattle Farming: This is the largest application market for alfalfa pellets. High-yielding dairy cows require high-quality roughage, and alfalfa pellets provide balanced digestible fiber and protein.

- Ruminant Farming: Used during fattening and breeding periods to provide high-quality nutrition, promote growth and enhance reproductive capacity.

- Livestock and Aquaculture: Alfalfa pellets provide essential fiber and protein. High-quality alfalfa pellets can also be incorporated into feed at appropriate ratios to improve gut health and supply natural vitamins.

Application in Biomass Fuels

Converting alfalfa into solid fuel pellets with stable calorific value provides a renewable, low-carbon, and environmentally friendly alternative to fossil fuels for industrial boilers or residential heating.

High-quality alfalfa hay contains inherent energy. When compressed into pellets, its density increases significantly, which increases the calorific value per unit volume, thereby meeting the fundamental requirements for use as fuel. Alfalfa also contains cellulose and lignin. During the pelleting process, lignin softens under high temperature and pressure, and acts as a natural binder. After cooling, it hardens the pellets, which is easy to burn. Alfalfa absorbs carbon dioxide through photosynthesis during its growth process. The carbon dioxide released when it is burned has a significantly smaller impact on the atmospheric carbon cycle than that from fossil fuels.

Applications in Soil Improvement

By producing alfalfa pellet fertilizer that is rich in organic matter, it improves soil quality and provides comprehensive nutrients for crops.

Alfalfa is rich in nitrogen, phosphorus, potassium, and various trace elements. The pellets require time to decompose in the soil, thereby releasing nutrients slowly. This makes them a long-lasting, natural slow-release fertilizer that prevents rapid nutrient loss. Its nitrogen, phosphorus, and potassium content is much lower than that of chemical fertilizers, so it cannot be expected to produce very rapid results like chemical fertilizers. It focuses more on building soil health. In organic farming, it is an excellent alternative to chemical fertilizers.

What are the advantages of biomass pellets making machines?

The alfalfa pellet mill for sale is characterized by its ability to physically reshape alfalfa’s form and value. It is not merely a processing device but a key tool for enhancing alfalfa’s value and advancing modern animal husbandry.

Extended Storage Duration

It can compress fluffy alfalfa hay into high-density pellets. The volume is reduced by 3-4 times, which greatly lowers storage space requirements and long-distance transportation costs.

Stable and Efficient Operation

This is the core feature of RICHI alfalfa pellet mill for sale. Key components are crafted from high-strength alloy steel and undergo specialized heat treatment processes, which are durable and wear-resistant. The equipment is robust and capable of withstanding long-term continuous high-intensity operation, with low failure rates and extended service life.

Significant Economic Benefits

The conversion of inexpensive roughage into high-value commercial pellets directly increases sales revenue. Most importantly, it reduces feed wastage by approximately 15%-20% during feeding, thus improving feed conversion efficiency. Additionally, automated feeding systems generate substantial savings in labor costs.

Intelligent and Effortless Operation

RICHI alfalfa pellet making machines are typically equipped with advanced PLC electronic control systems. They enable one-button start/stop and centralized control, while providing real-time monitoring of critical parameters such as main unit load and material temperature. Operation is straightforward, and they are equipped with automatic overload protection for safety and reliability.

Nutritional Balance

During the pelleting process, alfalfa hay and added nutrients are thoroughly blended together. This effectively prevents selective feeding by livestock, which ensures consistent nutritional balance in every mouthful of feed. Meanwhile, the high temperatures generated during compression provide sterilization benefits, and the low moisture content of the pellets significantly extends their shelf life.

Case Studies On Alfalfa Pellet Mills For Sale

At present, RICHI alfalfa pellet making machines have been exported to over 70 countries worldwide, with the number of projects continuing to grow. As essential equipment for ruminant feed pellet plants and wood pellet manufacturing plants, RICHI alfalfa pellet mills for sale have become the preferred choice for numerous customers.

10 T/H Alfalfa Pellet Mill

- Region: Northwest China

- Client Background: A large alfalfa planting cooperative in Ningxia. The cooperative operates a ten-thousand-acre alfalfa cultivation base. In the past, its primary business involved selling sun-dried alfalfa hay bales, which offered low product value-added and was highly susceptible to transportation distance and market price fluctuations.

- Customer Requirements: The client wanted to process alfalfa into high-value products to increase revenue. Additionally, they aimed to address the issues of bulky hay bales and extremely high long-distance transportation costs, and sell the products to more distant dairy farming hubs. Throughout this process, they sought to minimize nutrient loss and economic damage during storage and transportation.

2T/H Alfalfa Pellet Mill

- Region: North America

- Client Background: A agricultural enterprise in California, USA, integrating alfalfa cultivation, dairy cattle farming, and dairy processing. The enterprise annually generates substantial quantities of secondary alfalfa hay unsuitable for feeding high-yield dairy cows, along with byproducts such as grass meal and grass clippings from the processing operations.

- Customer Requirement: They are looking for a cost-effective solution to utilize low-grade alfalfa and byproducts, and to avoid waste. The customer aims to process these residues into biomass fuel pellets. These pellets are used in the farm’s own boiler system to provide thermal energy for farm facilities. They are exploring a sustainable farm operation model.

20T/H Alfalfa Pellet Mill

- Region: Middle East

- Client Background: A major feed import trading company in Saudi Arabia. Most of the country experiences arid climates with scarce water resources, which is not conducive to alfalfa cultivation. However, it boasts a thriving dairy and livestock industry with substantial demand for high-quality alfalfa feed. The country has long relied on imports of alfalfa hay bales from the United States, Spain, and other nations.

- Customer Requirements: High cost of importing hay bales, the customer seeks to reduce logistics expenses. Additionally, they aim to establish processing facilities in Sudan, where surrounding agricultural conditions are relatively favorable, thereby decreasing reliance on imported alfalfa. Furthermore, quality inconsistencies exist between imported hay bale batches, so they hope to obtain more standardized products.

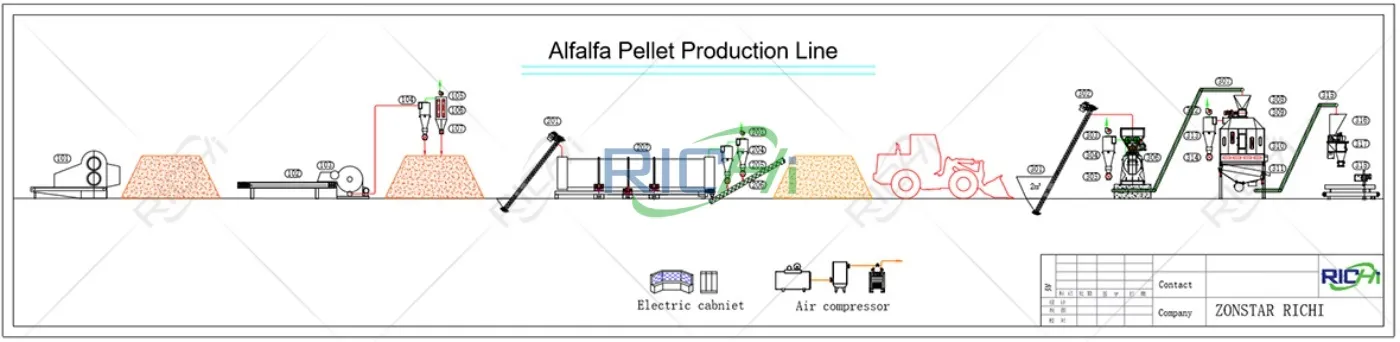

Alfalfa Pellet Production Line

RICHI Machinery not only offers high-efficiency alfalfa pellet mills for sale but also provides customers with straw pellet plant covering the entire process from raw material processing to final alfalfa pellets. This production line can manufacture alfalfa pellets, various grass pellets, feed pellets, and specialized pellets for ruminants, which can meet diverse market demands. Below is a detailed explanation of the core process flow for the 2-3T/H alfalfa pellet production line.

1. Raw Material Crushing—Alfalfa Crusher

A specialized bale-breaking crusher chops the long-stemmed alfalfa into 1-3 cm segments. This reduces material volume, prepares it for subsequent fine grinding, and ensures smooth feeding.

2. Drying Stage— Drum Type Dryer

Alfalfa hay sections with high moisture content are fed into the drum type dryer. Inside the drum, the material comes into full contact with high-temperature hot air, which quickly evaporates excess moisture. This process brings the material to a uniform and safe moisture content suitable for granulation.

3. Raw Material Crushing—Hammer Mill

After drying, the grass segments are fed into a hammer mill, where high-speed rotating hammers strike them into finer grass powder. The objective is to crush the raw material to a smaller particle size, which is crucial for subsequent conditioning and pelletizing. This forms the foundation for ensuring pellet quality and production yield.

4. Pelletizing Process—Alfalfa Pellet Mill

The tempered material is continuously and uniformly fed into the ring die chamber of the pellet mill. Under immense mechanical pressure, the material is forcibly squeezed through the die holes by the rollers, which forms dense cylindrical strands. These strands are then cut by external blades into pellets of a predetermined length.

5. Cooling System—Counter-flow Cooler

Pellets emerging from the alfalfa pellet mill are hot and soft, so they should be immediately fed into the counter-flow cooler. Cold air rapidly cools them to room temperature. This process sets the pellets’ shape, reduces moisture content, and hardens them for easier storage and transportation.

6. Screening Stage—Vibrating Screen

The cooled pellets contain a small amount of powder generated during transportation. They then enter the vibrating screen for separation. The vibrating screen separates qualified pellets and returns the screened fine powder to the conditioner for regranulation, which reduces material waste and improves yield.

Frequently Asked Questions

What raw materials are suitable for alfalfa pellet mills?

+

Alfalfa pellet making machines, especially professional feed pellet machines have a wide range of suitable raw materials and are by no means limited to alfalfa. Generally speaking, any plant-based material possessing a certain level of fiber content and binding potential is suitable for processing with an alfalfa pellet mill.

- Leguminous Forages: Alfalfa, clover, sainfoin, and red clover. These are high in protein and serve as core ingredients for premium feed pellets.

- Gramineous Forages: Ryegrass, Sudan grass, sheepgrass, Bermuda grass, etc.

- Crop straws: Corn stalks, wheat straw, rice straw, barley straw, etc. These materials are high in fiber and difficult to pelletize alone, so they usually need to mix with leguminous forage or binders.

- Other roughage: Rice straw, rice husks, etc.

What are the advantages of alfalfa pellets?

+

Alfalfa is known as the “king of forage crops,” renowned for its high yield, rich nutritional content, and exceptional protein levels. It has long served as a vital high-quality feed in livestock and poultry farming. Besides, alfalfa possesses excellent combustion properties as a biomass energy source. In recent years, an increasing number of customers have opted to process alfalfa into pellet form for animal feed or biomass fuel.

As animal feed:

- Reduces waste during feeding and improves feed utilization efficiency;

- Retains alfalfa’s rich protein, vitamins, and minerals to meet animals’ comprehensive nutritional needs;

- Uniform particle size effectively prevents selective eating by livestock, and ensures balanced nutrient intake.

As biomass fuel:

- Possesses high calorific value and excellent combustion efficiency with stable energy output;

- After compression, the volume is significantly reduced and density increased, which is convenient for storage and long-distance transportation;

- The combustion process produces almost no pollution, which is an environmentally friendly renewable energy source.

About rICHI

RICHI Machinery was established in 1995 and holds European CE certification, Swiss SGS certification, French BV certification, and ISO 9001 quality management system certification, with a complete international trade system. To better serve our global customers, We have also launched multiple platforms including Alibaba International, Google Ads, Made-in-China.com, and SEO optimization, and own a comprehensive cross-border e-commerce operation system. Up to now, our products have been exported to 108 countries and regions across Europe, the Americas, the Middle East, Asia, Africa, and Southeast Asia, which has earned the trust and recognition of a wide range of customers.

Information Sharing

Customized Solutions

After-Sales Service

Professional Certification