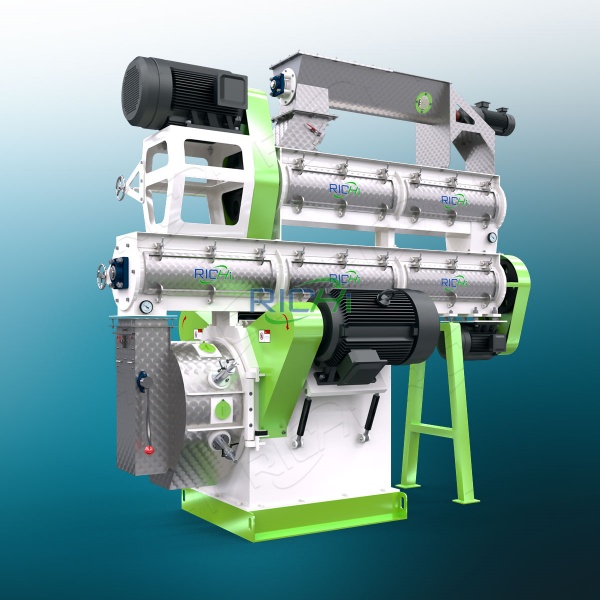

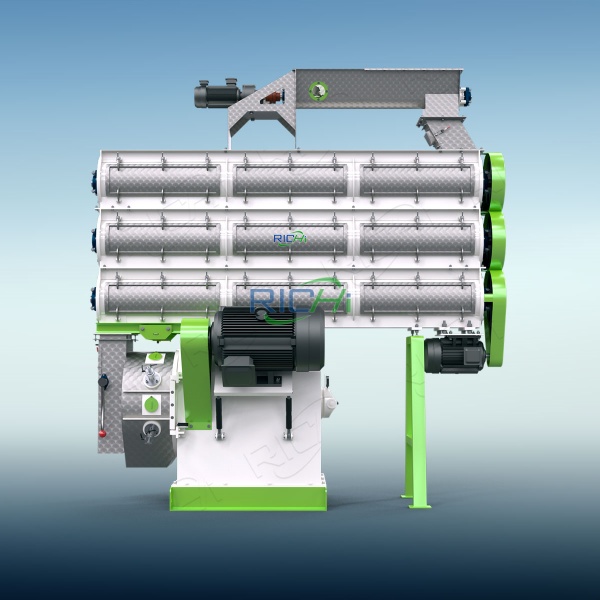

Animal Feed Granulator

RICHI MACHINERY

What Is A Animal Feed Granulator?

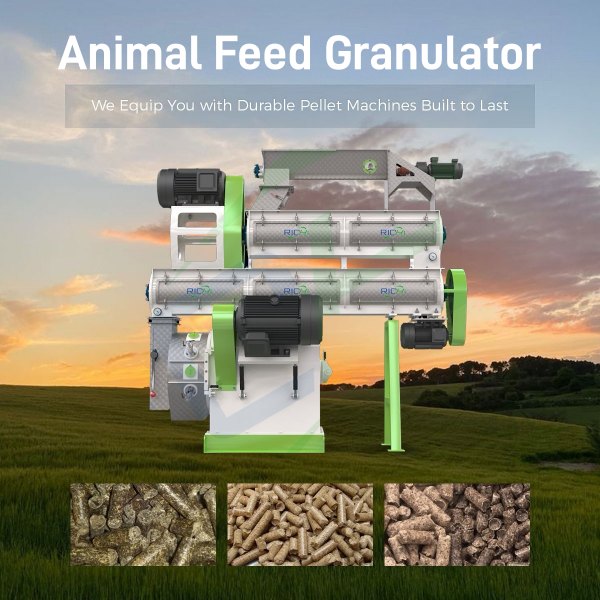

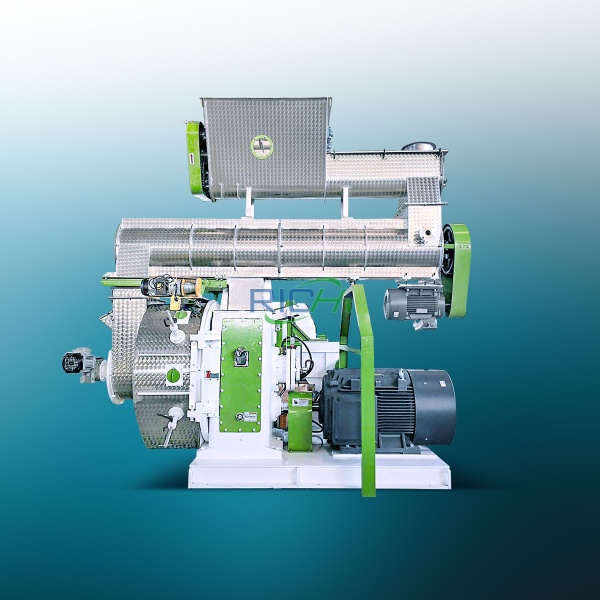

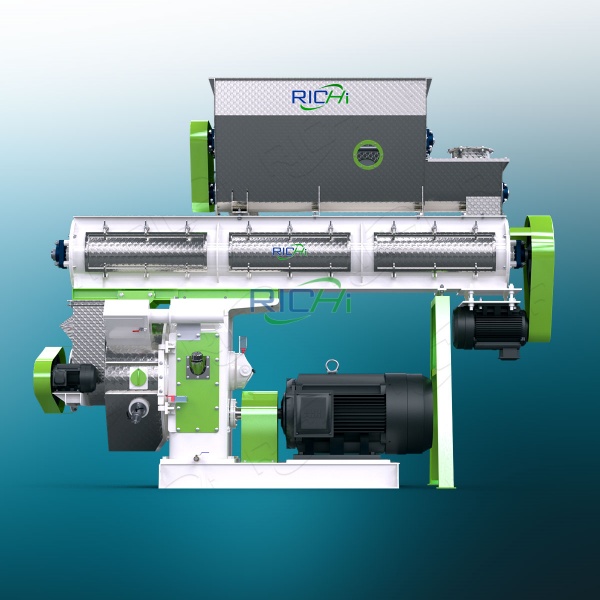

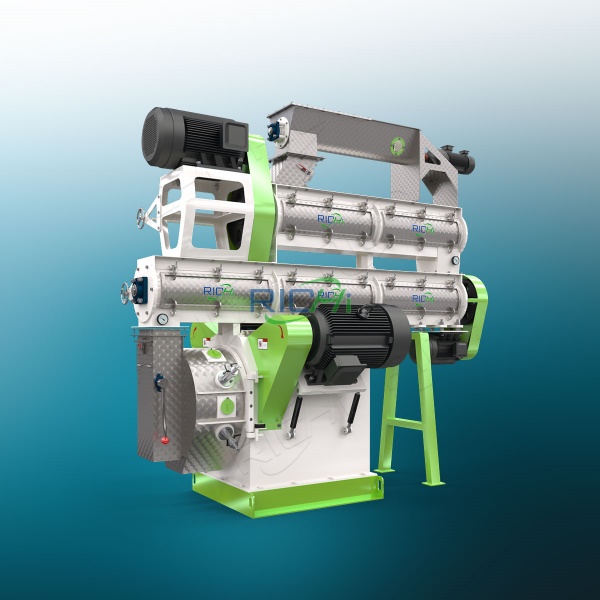

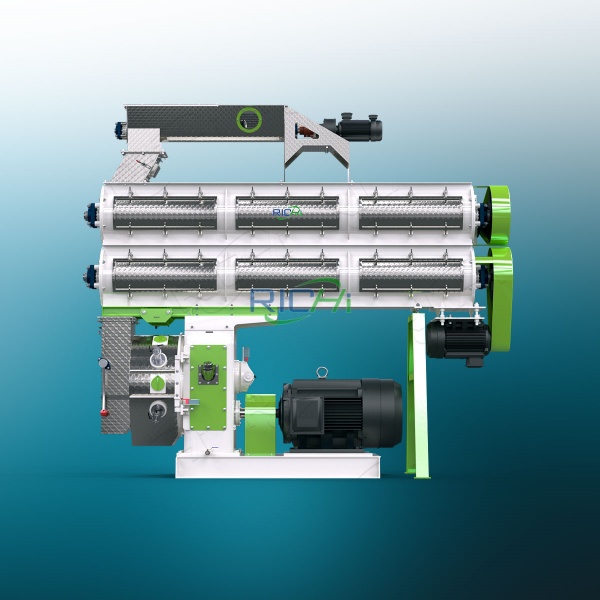

An animal feed granulator is a key processing machine designed to convert mixed powdered feed ingredients, such as grains, protein sources, vitamins, and minerals, into compact, high-density pellets. Through mechanical pressing and conditioning, the granulator improves the physical quality of feed, enhances nutrient absorption, and ensures consistent pellet size for different animal species including livestock, poultry, ruminants, and aquatic animals.

RICHI feed pellet granulators offer adjustable pellet diameters, high-efficiency transmission systems, and durable ring die or flat die structures, making them suitable for both small farms and large industrial feed plants. By minimizing feed wastage, reducing dust, improving storage stability, and enabling automated continuous production, this machine has become an indispensable machine in the entire feed manufacturing process.

Key Technical Features Of The Animal Feed Granulator

- All core bearings use SKF, offering higher stability, longer service life, and smoother running under continuous operation.

- Equipped with a Siemens motor to ensure reliable power output, reduced failure rate, and improved overall efficiency.

- The optimized mechanical design reduces machine volume, cuts energy consumption, and minimizes operating noise.

- Feeding speed can be precisely adjusted according to different formulas and material characteristics, ensuring stable pelletizing.

- All parts in contact with raw materials are made of stainless steel to avoid contamination and improve pellet quality and durability.

- Built-in safety pin mechanism protects the machine by automatically stopping operation under overload conditions.

- Two cutters allow flexible adjustment of pellet length; the handle adjusts the distance between cutter and ring die for accurate cutting.

- The large handle adjusts cutter position; the small handle works as a limiter to prevent cutter–ring die collision and ensure safe operation.

- Different pellet diameters and hardness levels can be produced by changing ring dies, making the machine suitable for various animals and farms.

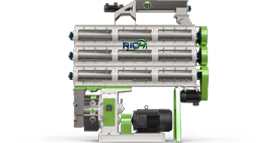

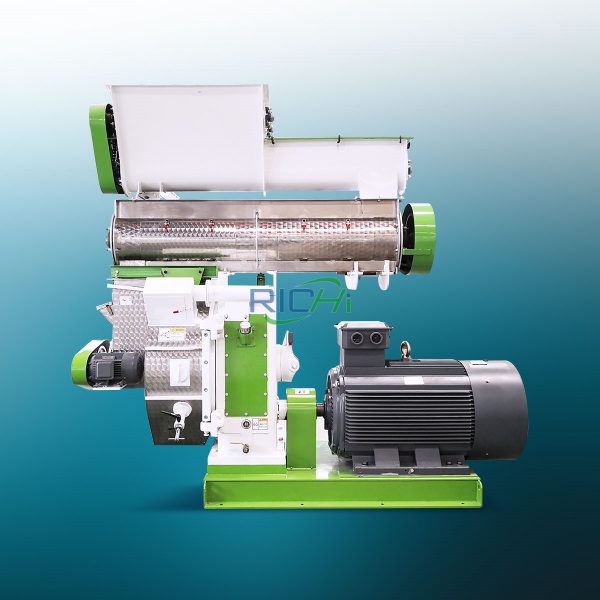

The Main Parts Of The Animal Feed Granulator

Frequency impeller feeder

The feeder uses a variable-frequency motor with overload protection to ensure stable and adjustable feeding. It allows different materials to be supplied at the proper rate and keeps the pellet mill running at optimal efficiency.

Conditioner

The conditioner uses saturated steam to mature and gelatinize materials, improving pellet quality and hygiene. Single-layer, double-layer, and triple-layer designs are available, and boilers can be supplied for continuous steam support.

Pelletizing chamber

The pelletizing chamber is structurally optimized to ensure material uniformity and stable compression performance. The improved chamber design allows the feed pellet machine to maximize its output and maintain consistent pellet quality.

Stainless ring die

The stainless-steel ring die provides high durability, strong corrosion resistance, and stable pellet formation. A variety of die sizes are available, allowing users to produce pellets of different diameters and achieve better economic efficiency.

Siemens motor

The animal feed granulator is powered by a high-efficiency Siemens motor, which reduces energy consumption and ensures stable and reliable operation. A high protection rating guarantees longer service life, safer operation, and higher production stability.

Electric control cabinet

The independent electrical control cabinet allows separate control of the pellet mill and provides overload protection and emergency stop functions. It enables safe operation and allows maintenance without stopping the entire production line.

Suitable Animal Feed Granulators for Different Types of Feed

RICHI Machinery feed granulators are flexibly adaptable to different raw materials, animal types, and production demands. Whether for poultry, livestock, ruminants, or aquatic feed, we provide tailored solutions to ensure stable equipment operation and the production of high-quality pellets. With their flexible configuration and wide applicability, the system can meet the diverse needs of farms and large-scale commercial production.

Poultry Feed Pellet Machine

Livestock Feed Pellet Machine

Ruminant Feed Pellet Mill

Aquatic Feed Pellet Machine

Technical Specifications & Model Of Animal Feed Granulator For Sale

Choosing the right feed granulator machine begins with understanding its technical specifications, structural features, and model range. Different farms and feed plants require different production capacities, so we provide a complete lineup of models with various outputs, motor power options, ring die sizes, feeding structures, and applicable raw materials. Whether your goal is small-scale feed processing or a large, fully automated commercial production line, our granulators allow you to match the ideal machine with your budget and capacity needs. The animal feed granulator price ranges from $7,000 to $85,000, depending on the model, capacity, and configuration.

SZLH250 Small Animal Feed Granulator

Capacity:

1-2T/H

Main Power:

22KW

SZLH320 Animal Feed Granulator

Capacity:

3-4T/H

Main Power:

37KW

SZLH350 Feed Pellet Mill

Capacity:

5-6T/H

Main Power:

55KW

SZLH420 Feed Granulator Machine

Capacity:

10T/H

Main Power:

110KW

SZLH508 Animal Feed Granulator Machine

Capacity:

15T/H

Main Power:

160KW

SZLH558 Feed Pellet Machine

Capacity:

20T/H

Main Power:

185KW

SZLH678 Feed Pellet Making Machine

Capacity:

30T/H

Main Power:

250KW

SZLH768 Commercial animal feed granulator

Capacity:

40T/H

Main Power:

315KW

Related Cases Of The feed Pellet granulator

With over 30 years of experience in feed equipment manufacturing, our animal feed granulators have been installed in more than 140 countries and regions worldwide. From livestock and poultry farms to large commercial feed plants, our solutions cover a wide range of production capacities, raw materials, and technical requirements. Each project reflects our commitment to stable performance, consistent pellet quality, and customized engineering support. The following case selections provide a clear view of how our granulators operate in real production environments across different markets and conditions.

Frequently Asked Questions

To help you better understand our animal feed granulators, we have compiled a series of frequently asked questions covering machine selection, capacity planning, raw materials and pricing. These answers are based on decades of field experience and real customer cases from more than 140 countries and regions. Whether you are new to feed pellet production or planning to upgrade an existing plant, this FAQ section will provide clear and practical guidance.

–

How can I get an accurate feed Pellet granulator price?

To provide you with a precise and personalized quotation, we will need some key information about your production needs. This includes the output capacity you are planning for, the types of raw materials you intend to use, the required pellet size, your local power supply specifications, and whether you need only the granulator or a complete feed production line.

With these details, our technical and sales teams can evaluate the appropriate model and configuration for your project. Once everything is confirmed, we will prepare a detailed quotation that clearly outlines the equipment specifications, optional features, and pricing, ensuring you receive a solution that matches both your budget and your production goals.

–

How do I choose the right model for my production needs?

Choosing the right animal feed granulator begins with understanding the scale and requirements of your production. The most important factors include your expected hourly output, the types of raw materials you will process, the pellet diameter you need, and the stability of your local power supply. Additional considerations, such as the layout of your workshop, steam conditions, and whether the granulator will be used in a new plant or integrated into an existing line, also play a key role in model selection.

Once these details are clear, we can help you determine the suitable ring die size, motor power, and compression ratio needed to achieve optimal pellet quality and energy efficiency. By matching the machine specifications with your actual working conditions, you can ensure stable operation, lower maintenance costs, and the best long-term performance for your feed production.

–

What raw materials can the animal feed granulator process?

Our granulator is designed with wide raw-material adaptability, suitable for most feed formulas used in livestock, poultry, ruminant, and aquatic production. It can process common agricultural by-products such as corn, wheat, barley, soybean meal, rice bran, and sorghum. Protein-rich ingredients like fish meal, meat meal, and various oil cakes are also compatible, as well as fibrous materials including alfalfa, grass powder, and straw meal.

Many users also add functional ingredients such as vitamins, minerals, amino acids, enzymes, or premixes, and the granulator can handle them efficiently if properly mixed. Materials for aquafeed or special feed formulas can also be processed effectively with appropriate moisture and particle size. Overall, as long as raw materials are crushed to the proper size (usually ≤3 mm) and moisture-adjusted, the machine produces stable, uniform, and high-density pellets. We can provide guidance if you have specific ingredients to ensure optimal pelletizing performance.

–

I run a family farm. Can one granulator meet both poultry and livestock feed needs?

Yes, a single animal feed granulator can meet the diverse feed requirements of a small or family farm. By selecting the appropriate ring die and adjusting conditioning parameters such as moisture content and steam, the same machine can produce pellets suitable for poultry, pigs, cattle, and even small ruminants.

Many farms successfully use one granulator to produce multiple feed types. The key is to follow recommended formulas and operate the machine according to the raw material characteristics and pellet size requirements. With proper operation, the granulator can deliver consistent pellet quality, minimize feed waste, and improve overall farm efficiency.

–

My raw materials contain high fiber (such as grass powder). Will the pelletizing effect be affected?

High-fiber raw materials can pose challenges in pelletizing if not properly processed, but our animal feed granulators are designed to handle such materials efficiently. To achieve stable pellet formation, it is important to select a suitable ring die with an appropriate compression ratio and adjust conditioning parameters, such as moisture content and steam input.

Many farms use high-fiber ingredients like alfalfa, grass powder, or straw meal for ruminants and aquaculture feed. With correct ring die selection, pre-crushing, and proper moisture control, the granulator can produce uniform, high-density pellets. Our technical team can provide guidance on die selection, feed formulas, and operating parameters to ensure optimal pellet quality for high-fiber materials.

–

Can your granulator integrate with my existing crusher, mixer, or packing machine?

Yes, our animal feed granulators are designed to be compatible with most standard feed production equipment. Whether you already have a crusher, mixer, or automatic packing system, our granulators can be integrated into your existing line with minimal modification.

We provide technical support for layout planning, connection interfaces, and workflow optimization. This ensures smooth operation, efficient material flow, and consistent pellet quality throughout the production process. Many clients worldwide have successfully integrated our granulators into pre-existing systems, achieving higher productivity without replacing their entire setup.