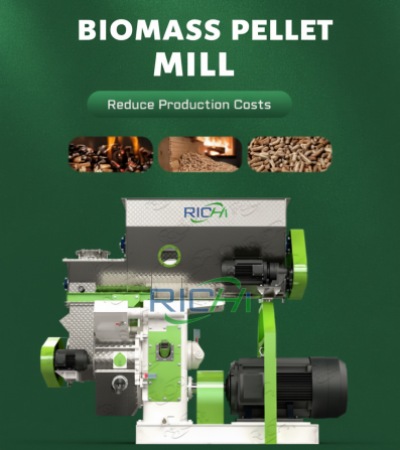

Biomass Pellet Mill

RICHI MACHINERY

What Is A Biomass Pellet Mill?

A biomass pellet mill is a specialized machine designed to convert loose, low-density biomass materials into compact, high-density pellets that are easy to transport, store, and burn. It typically processes materials such as wood chips, sawdust, rice husks, straw, coconut shells, palm residues, and various agricultural or forestry wastes. By applying high pressure and mechanical extrusion through a ring die or flat die system, the mill reshapes raw materials into uniform pellets with stable size, high calorific value, and clean combustion performance.

Beyond improving fuel value, a biomass pellet machine plays a vital role in sustainable energy development. It transforms waste biomass into renewable, eco-friendly fuel that can replace coal, reduce carbon emissions, and support biomass power plants, industrial boilers, home heating systems, and commercial energy projects. Due to its stable output, low operational cost, and adaptability to various materials, the biomass pellet mill has become a key component of modern biomass pellet production lines.

Technical Specifications & Model Of Biomass Pellet Mill For Sale

To help customers choose the most suitable machine for their production needs, we provide different models of biomass pellet mill for sale with different capacities, power configurations, and ring die sizes. Each model is designed to process various biomass materials efficiently and produce high-density pellets with stable performance. Below you will find a detailed comparison of technical specifications and model options to guide your selection and investment.

MZLH320 Biomass Pellet Making Machine

- Capacity: 0.2-0.3T/H

- Main Motor Power: 22KW

- Price: 10,000-20,000 USD

MZLH350 Biomass Pellet Granulator Machine

- Capacity: 0.3-0.5T/H

- Main Motor Power: 37KW

- Price: 20,000-25,000 USD

MZLH420 Biomass Pellet Machine

- Capacity: 1-1.2T/H

- Main Motor Power: 90KW

- Price: 25,000-35,000 USD

MZLH520 Biomass Pellet Mill

- Capacity: 1.5-2T/H

- Main Motor Power: 132KW

- Price: 40,000-50,000 USD

MZLH678 Biomass Pellet Mill

- Capacity: 2.5-3T/H

- Main Motor Power: 200KW

- Price: 60,000-70,000 USD

MZLH768 Biomass Pellet Maker

- Capacity: 3-4T/H

- Main Motor Power: 315KW

- Price: 80,000-90,000 USD

RICHI MACHINERY

How Biomass Pellet Machine Produce Biomass Pellet

In a complete biomass pellet production system, the biomass pellet mill is the core equipment that transforms processed raw materials into finished pellets. After materials go through crushing, drying, and fine mixing, they enter the pellet mill for continuous pelletizing.

The machine works seamlessly with upstream and downstream equipment to ensure stable capacity, uniform pellet quality, and efficient production.

Complete Biomass Pellet Mill System

A complete biomass pellet production process is a systematic and highly coordinated workflow that transforms raw agricultural and forestry residues into clean, high-density fuel pellets. From material preparation to final packaging, every step is designed to improve efficiency, ensure stable quality, and support continuous industrial-scale operation. Understanding the full process helps customers choose the right equipment, optimize investment costs, and build a pellet plant that meets local market demands and energy standards.

Auxiliary Equipment for Complete Biomass Pellet Mill Plant

A complete biomass pellets production line relies not only on the core biomass pellet mill but also on a set of auxiliary equipment that ensures smooth, efficient, and high-quality pellet production. From raw material preparation to drying, mixing, cooling, and packaging, each piece of auxiliary machinery plays a crucial role in supporting continuous operation and optimizing the final product. Choosing the right combination of equipment enhances productivity, reduces energy consumption, and guarantees uniform pellet quality suitable for energy generation and heating applications.

Wood Shredder Machine

The wood shredder machine reduces bulky materials like branches and wood blocks into smaller pieces, ensuring smooth feeding for the next chipping or grinding stage.

Drum Chipper

The drum chipper processes wood into uniform chips, providing an ideal size for hammer milling and improving overall material handling efficiency.

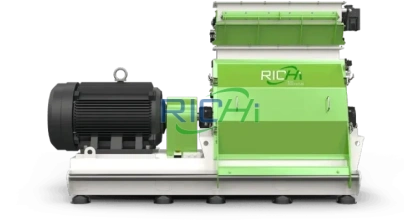

Hammer Mill

The hammer mill grinds biomass materials into fine powder suitable for pelletizing, helping increase pellet forming rate and consistency.

Dryer Machine

The dryer machine adjusts raw material moisture to the optimal level for pelletizing, ensuring stable production and better pellet quality.

Wood Pallet Crusher

The wood pallet crusher breaks down waste pallets and wooden boxes into reusable biomass material for further processing.

Pellet Cooler Machine

The pellet cooler reduces the heat and moisture of newly formed pellets, enhancing hardness and stability for storage and transport.

.png)

Vibrating Screen

The vibrating screen removes powder and irregular pellets, ensuring uniform final product quality.

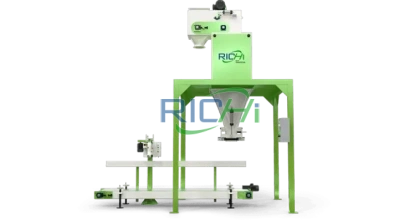

Packaging System

The packaging system automatically weighs, fills, and seals pellets, supporting both small bag and jumbo bag packaging with clean and efficient operation.

Related Cases Of The Biomass Pellet Mill

As the demand for clean and renewable energy continues to rise, biomass pellet machines provided by RICHI Machinery have been widely installed across Asia, Europe, Africa, and the Americas. These projects help customers transform agricultural and forestry residues into high-value biomass fuel pellets. The following real cases illustrate how different regions leverage our solutions to achieve stable production, reduce energy costs, and enhance sustainability.

Video Of RICHI Biomass Pellet Mill

The following videos provide a clear, real-world demonstration of the RICHI biomass pellet mill in action. From the overall machine appearance to the actual pelleting process, you can see how the equipment handles multiple challenging biomass materials—including EFB fibers, miscanthus, hemp residues, and sunflower husks—while maintaining stable output and consistent pellet quality. These videos helps you visually understand the machine’s versatility, durability, and reliable performance across different biomass applications.

Frequently Asked Questions

This section presents some of the most frequently asked questions about RICHI biomass pellet mills. It is designed to give customers a clear and practical reference when considering machine selection, operation, and maintenance, helping them better understand the equipment before making decisions.

–

What raw materials can a pellet mill process? Can I use mixed materials such as wood chips and straw?

A biomass pellet maker is designed to process a wide range of fibrous, low-density, and renewable materials. Common raw materials include wood chips, sawdust, shavings, bamboo, rice husk, straw, palm fiber, peanut shells, sunflower husk, and other agricultural or forestry wastes. You can use mixed materials such as wood chips + straw or sawdust + rice husk. However, for optimal pelletizing performance, the mixed raw materials should have similar moisture content, particle size, and fiber characteristics. Proper mixing and uniform feeding are also important to ensure stable output and consistent pellet quality.

In addition, we also offer specialized biomass pellet machines designed for different raw materials, such as wood pellet machine, grass pellet mill, EFB pellet machine, alfalfa pellet machine, rice husk pellet machine, bamboo pellet machine, and more, ensuring the best pelletizing results for every specific material type.

–

What is the price range of a RICHI biomass pellet mill?

The RICHI biomass pellet mill price generally ranges from $10,000 to $90,000, depending on the model, production capacity, and included features. Small-scale machines suitable for pilot projects or small farms are relatively low in price, while medium to large industrial models, often integrated with auxiliary equipment or customized for specific raw materials, are more expensive.

Investors should also consider additional costs such as installation, transportation, building infrastructure, and ongoing maintenance when planning a complete pellet production project. Choosing the right model for your output requirements and raw materials is essential to ensure a reasonable return on investment.

–

Can a biomass pellet mill be integrated into a complete production line?

Yes. A RICHI biomass pellet maker can be seamlessly integrated with auxiliary equipment such as crushers, dryers, conveyors, coolers, sieves, and packing machines to form a fully automated pellet production line. Proper line design ensures smooth material flow, minimizes downtime, and maximizes return on investment.

- Crushing: Raw materials such as wood chips, straw, rice husks, or palm fibers are crushed into small particles (3–5 mm) to prepare for pelletizing.

- Drying: Crushed materials are dried to reduce moisture to 12–18%, ensuring optimal conditions for pellet production.

- Pelletizing: Dried materials are pressed in a biomass pellet mill under high pressure and temperature, forming dense and uniform pellets.

- Cooling: Fresh pellets are cooled to harden and stabilize them, preventing deformation or breakage during storage and transport.

- Screening: Cooled pellets are sieved to remove fines and broken particles, ensuring consistent quality.

- Packaging: Finished pellets are weighed and packed into bags or jumbo bags for storage, transport, and sale.

–

Can I expand from a single pellet mill to a full production line later?

Yes. Many users start with a single pellet mill to test the market or reduce initial investment. Later, you can add crushers, dryers, coolers, conveyors, sifters, and packing machines to build a complete biomass pellet production line. Choosing a scalable layout in advance makes future expansion easier and more cost-effective.

–

How to choose the right machine for my Project?

Choosing the right biomass pellet mill depends on several key factors related to your production goals, raw material conditions, and investment plans.

- First, consider the type and properties of your raw materials—such as hardness, fiber content, and moisture level—because different materials require different compression strength and die configurations.

- Second, evaluate your expected production scale and working hours per day to determine the appropriate machine size, motor power, and durability level.

- You should also assess the stability of local electricity supply, planned automation level, and available installation space to ensure smooth and continuous operation.

- Finally, choose a reliable manufacturer that provides complete technical support, spare parts, after-sales service, and project designing. A trustworthy supplier greatly reduces operational risks and long-term costs.