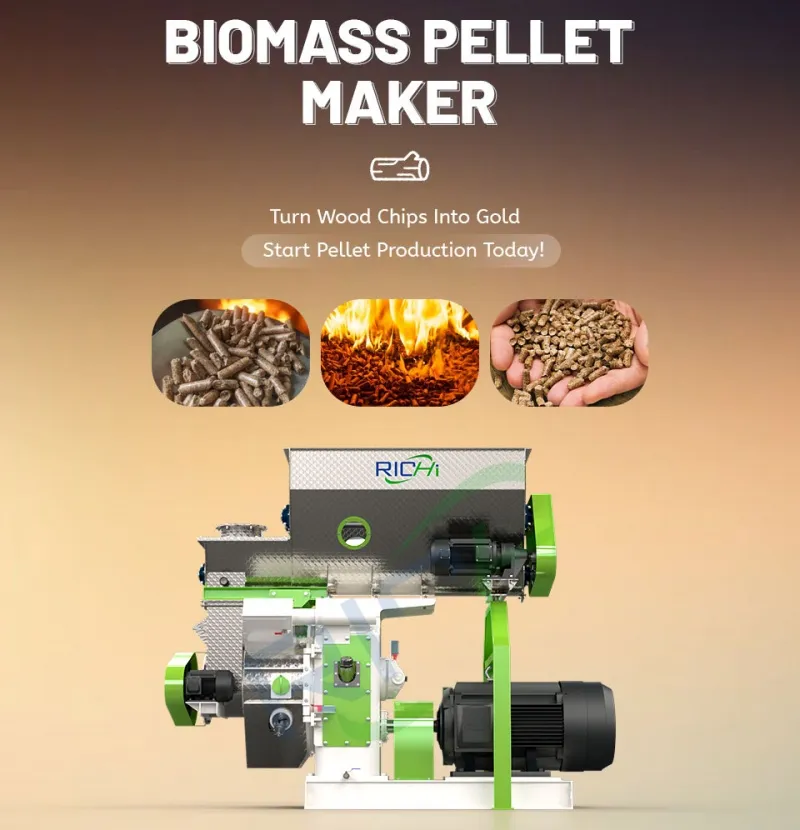

Biomass Pellets Making Machine

RICHI Machinery Factory possesses superior intelligent and automated technologies, and thus our biomass pellets making machine productivity and product quality are at the forefront of the industry.

Introduction of Biomass Pellets Making Machine

Specifically developed for the utilization of renewable resources

A biomass pellets making machine is a mechanical device that uses physical compression to transform various agricultural and forestry waste materials which are originally loose, irregular, and difficult to store and transport into high-density, uniformly shaped solid fuel pellets. Therefore, it realizes clean energy production and enables the efficient recycling of resources.

Nearly all plant-based waste materials can serve as raw materials for biomass pellets making machines, including forestry residues such as wood chips, sawdust, branches, and bark, as well as agricultural residues like corn stalks, wheat straw, rice husks, cotton stalks, and sugarcane bagasse. These raw materials all require crushing and must be processed with the appropriate moisture content.

The biomass pellets produced are primarily used as a clean fuel to replace coal in industrial boilers, power stations, home fireplaces, and similar applications. They offer high combustion efficiency and burn cleaner than the raw materials themselves. Biomass pellets can also serve as feed for ruminants, which makes them easier for livestock to consume and reduces waste. Biomass pellets transform waste into clean energy or feed, offering both environmental and economic benefits.

How Does a Biomass Pellets Making Machine Work?

Biomass pellets making machine is a key type of biomass energy equipment. This machinery processes plant-based waste into uniform solid fuel pellets with high density and burning efficiency through mechanical compression molding. Let’s explore the primary working principle of RICHI Machinery’s MZLH series biomass pellets making machine.

Firstly, the raw materials for making biomass pellet fuel are put into the barrel of the feeder, because it is rotating, so it is easy to fling the raw materials to the inner wall under the action of centrifugal force, so as to form a uniform ring-shaped layer of materials.

And then, after the ring die and the pressure roller’s intense extrusion, the raw materials will be extruded out of the die holes with a cylindrical shape and the raw material will be extruded from the hole of the die in cylindrical shape and cut in to uniform pellets by the cutting device, that is, biomass pellets.

- Production Capacity: 0.2-40 tons per hour

- Main Motor Power: 22-250 kw

- Finished Pellets Diameter: 4-12 mm

RICHI MACHINERY

Components of the Biomass Pellets Making Machine

We design each unit with high quality materials, such as stainless steel construction, Siemens motors, and SKF bearings, which ensures the biomass pellets making machine’s high efficiency, stability, and excellent results.

Biomass Pellets Making Machine Specifications

Below are the specifications for our biomass pellets making machines. If you don’t know how to select, please contact us directly. Additionally, we can customize biomass pellet machines to meet individual customer requirements.

MZLH320 Biomass Pellets Making Machine

- Production Capacity: 0.2–0.3 T/H

- Main Motor Power: 22 kw

- Arch-Breaking Feeder Power: 2.2 kw

- Forced Feeder Power: 0.75 kw

- Ring Die Inner Diameter: 320 mm

- Finished Pellet Diameter: 4–12 mm

MZLH350 Biomass Pellets Making Machine

- Production Capacity: 0.3-0.5 T/H

- Main Motor Power: 37 kw

- Arch-Breaking Feeder Power: 2.2 kw

- Forced Feeder Power: 0.75 kw

- Ring Die Inner Diameter: 350 mm

- Finished Pellet Diameter: 4–12 mm

MZLH420 Biomass Pellets Making Machine

- Production Capacity: 1.0-1.2T/H

- Main Motor Power: 90 kw

- Arch-Breaking Feeder Power: 3 kw

- Forced Feeder Power: 1.5 kw

- Ring Die Inner Diameter: 420 mm

- Finished Pellet Diameter: 4–12 mm

MZLH520 Biomass Pellets Making Machine

- Production Capacity: 1.5-2.0 T/H

- Main Motor Power: 132 kw

- Arch-Breaking Feeder Power: 3 kw

- Forced Feeder Power: 1.5 kw

- Ring Die Inner Diameter: 520 mm

- Finished Pellet Diameter: 4–12 mm

MZLH678 Biomass Pellets Making Machine

- Production Capacity: 2.5-3.0 T/H

- Main Motor Power: 185 kw

- Arch-Breaking Feeder Power: 3 kw

- Forced Feeder Power: 1.5 kw

- Ring Die Inner Diameter: 678 mm

- Finished Pellet Diameter: 4–12 mm

MZLH768 Biomass Pellets Making Machine

- Production Capacity: 3.0-4.0 T/H

- Main Motor Power: 250 kw

- Arch-Breaking Feeder Power: 4 kw

- Forced Feeder Power: 1.5 kw

- Ring Die Inner Diameter: 768 mm

- Finished Pellet Diameter: 4–12 mm

Why Produce Biomass Pellets?

The production of biomass pellets is a process of transforming waste into valuable resources and upgrading energy sources in essence.

Clean Combustion

RICHI biomass pellet machinery employs high-efficiency combustion technology, and the emission of pollutants such as sulphur dioxide is significantly lower than that of coal, which is a relatively clean fuel. Processing agricultural and forestry waste into pellets can reduce smog and air pollution.

Reduce Energy Costs

For factories, farms, schools and other locations where heat or steam is required, using biomass pellets as an alternative to natural gas, diesel or electricity can significantly reduce energy costs.

Convenient For Storage and Transportation

Loose wood shavings, straw and other biomass materials possess low bulk density and substantial volume, so it results in prohibitively high transportation and storage costs. When compressed into pellets, their energy density increases significantly, which makes them easier for long-distance transport and large-scale storage.

Significant Economic Benefits

The raw material costs for biomass pellets are low, and their operational expenses as a fuel typically are much lower than those of oil, electricity, and natural gas. They are comparable to or even lower than coal, which provides users with an exceptionally cost-effective energy option.

What are the advantages of biomass pellets making machines?

A biomass pellet mill is not only an equipment, but also a solution for green and clean biomass energy.

High Output And Low Energy Consumption

Stable Performance

The biomass pellet machine employs variable-frequency feeding to effectively prevent uneven feeding caused by voltage fluctuations. It is equipped with a high-performance Siemens motor and an operational control system, which ensures long-term stable and reliable performance with minimal downtime.

Extensive Applications

Our equipment has been successfully deployed in various areas including timber processing, renewable energy, domestic and industrial heating, and agriculture. Regardless of your industry, whenever biomass raw material processing is involved, we can provide the most suitable solution.

Energy Conservation and Environmental Protection

The RICHI biomass pellets making machine employs advanced pelleting technology to efficiently transform crushed raw materials into compact biomass pellets, serving as a clean energy source that significantly enhances energy utilization efficiency.

Safe and Simple

The entire equipment features a stainless steel construction with overload protection devices to extend service life. It incorporates a one-touch start/stop design, while an advanced automatic control system ensures operation is more convenient and easy.

Case Projects of the Biomass Pellets Making Machine

Up to now, RICHI Machinery has successfully assisted over 300 enterprises in achieving resource recovery from waste, with a cumulative waste processing volume exceeding one million tons, which has created additional revenue of hundreds of millions of yuan for clients.

2T/H Biomass Pellets Making Machine

- Country: Sweden

- Raw Materials: including sawdust and wood shavings from sawmills, and branches, tree tops, and low-grade timber generated during forest tending and harvesting operations.

- Client Background: A small sized factory requiring process steam, which converted its boiler to burn biomass pellets to reduce carbon tax costs and achieve environmental targets.

5T/H Biomass Pellets Making Machine

- Country: Romania

- Raw Materials: Specializing in solid wood furniture, the facility generates 50 tons of wood waste daily. High disposal costs and significant environmental pressure need a solution.

- Client Background: We provided technical support to a client in Romania for the installation of a wood pellet production line. Romania has a wide range of forest areas, and wood chips generated during wood processing can be transformed into high-quality raw materials for biomass fuel through our technology.

10T/H Biomass Pellets Making Machine

- Country: United States

- Raw Materials: The farm cultivates thousands of acres of alfalfa and sheep’s fescue as primary roughage for dairy cattle.

- Client Background: Each year following harvest season and during feed rotation, substantial quantities of surplus, lower-grade hay are produced. This hay is inexpensive but troublesome to handle. The farm requires substantial thermal energy to milk parlour equipment, winter barn insulation, and residential areas. Consequently, it has been decided to invest in a smallscale biomass pellet production line to convert surplus hay into a valuable resource.

How to Select a Suitable Biomass Pellets Making Machine?

1.Clarify Core Requirements

The selection of biomass pellet raw materials is crucial. Woody raw materials, particularly hardwoods, present greater compaction challenges and demand higher-quality machinery. Among agricultural straws, corn stalks and wheat straws possess distinct fibre structures, which are usually more difficult to form than wood chips, so they require greater pressure and suitable dies. Subsequently, based on your raw material supply and market demand, you should select a production capacity slightly exceeding current requirements to allow scope for future expansion. If you require to build a 1T/H biomass pellet plant, we recommend selecting either an MZLH420 or MZLH520 biomass pellets making machine.

2.Determining Biomass Pellets Maker Type

Biomass pellets making machines are typically categorized into two types: ring die pellet makers and flat die pellet makers. These two types exhibit numerous differences in design, operating principles, and production capacity. The biggest distinction is that the production capacity of ring die pellet makers far exceeds that of flat die pellet makers. Due to their high output and low energy consumption, many customers opt to purchase ring die biomass pellets makers for producing biomass pellets.

3.Examination of Core Components

The core lifespan and performance of a biomass pellets making machine depends on its key components.

Ring dies must be manufactured from high-quality alloy steel to ensure exceptional wear resistance. RICHI not only holds a practical novelty patent certificate for ring die pellet machines, but the materials and manufacturing processes for these dies have undergone extensive testing and experimentation. Motors are selected from national standards or renowned brands and have sufficient power. RICHI biomass pellets making machines all use Siemens motors, which ensures that the biomass fuel pellet machine maintains stable production efficiency for a long time.

4.Selecting the Appropriate Manufacturer

Key factors in choosing a manufacturer include whether their services encompass technical guidance, die supply and repair, and prompt after-sales service response. RICHI Machinery welcomes you to bring your raw materials for on-site machine trials at our factory, because we know this is the most direct way to verify machine performance, forming results, and actual output.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.

Frequently Asked Questions

What raw materials can be used to manufacture biomass pellets?

+

Almost all plant-based waste materials are suitable, primarily including:

- Forestry residues: wood shavings, wood chips, sawdust, branches, etc.

- Agricultural residues: maize stalks, wheat straw, rice husks, peanut shells, sugarcane bagasse, etc.

- Energy crops: Elephant grass, switchgrass, etc.

- Other: Hay or certain organic waste materials.

- Key requirements: Raw material moisture content must be controlled between 10% and 15%, and crushed to a sufficiently fine particle size.

What is the service life of the ring die and press rollers?

+

As the ring die and press rollers are wear parts, their service life usually ranges from several hundred to several thousand operating hours. The duration depends on the following factors:

- Raw materials: Hard materials such as rice husks and bark wear extremely quickly, whereas soft wood shavings wear much more slowly.

- Material: Components made from high-quality alloy steel and heat treated with carburizing have a significantly longer service life.

- Maintenance: Regular servicing can significantly extend service life.

What is the difference between ring die pelletizer and flat die pelletizer? Which one should I choose?

+

- Ring die biomass pellets making machine: High output, excellent pellet quality, and durable construction make it the preferred choice for commercial production. However, it has high investment and maintenance costs.

- Flat die biomass pellets making machine: Featuring a straightforward construction, economical pricing, and straightforward die-changing, it is well-suited for small-scale operations or users with limited budgets. However, its output capacity and pellet hardness typically are not as high as those of ring-die machines.

- Therefore, we recommend that if you plan to undertake continuous, large-scale commercial production, you should opt for a ring die pelletizer.