Cattle Feed Pellet Machine

Cattle feed pellet machine is designed to efficiently convert grains, forage, and feed ingredients into high-quality cattle feed pellets. With stable performance and flexible capacity options, it is ideal for modern cattle farms and commercial feed mills seeking cost-effective feed production.

General Introduction for RICHI Cattle Feed Pellet Machine

Cattle feed pellet machine is designed to efficiently produce high-quality pellet feed for cattle. By processing grains, protein-rich ingredients, and roughage into uniform pellets, the machine improves feed utilization, reduces waste, and ensures consistent nutrition for livestock.

RICHI cattle pellet machine is a high-performance feed processing solution designed for modern cattle farms and commercial feed mills. It efficiently produces high-quality cattle feed pellets, helping farmers improve feed utilization, reduce waste, and provide consistent nutrition for cattle.

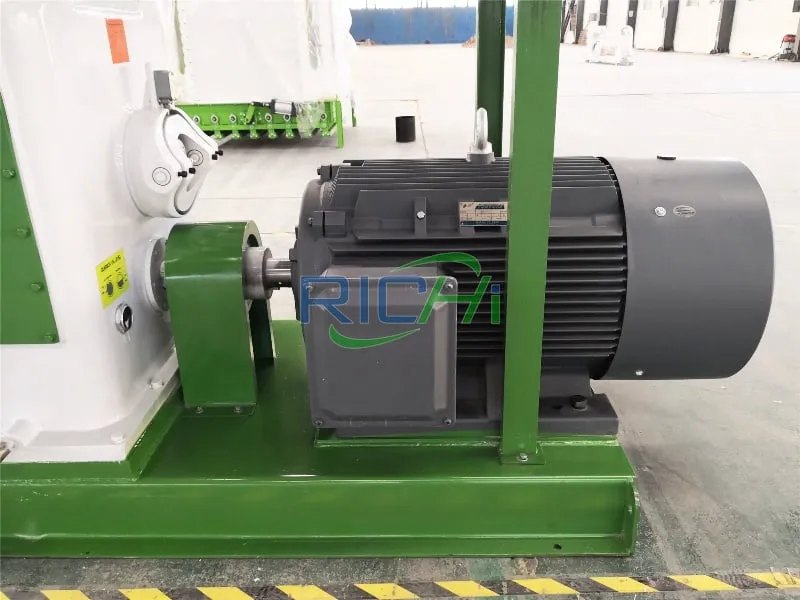

The machine primarily features a high-torque ring die pellet system, ensuring stable pellet formation with minimal dust. Operators can easily adjust pellet size and density to suit different cattle growth stages. Its robust construction guarantees long-term, low-maintenance operation. For smaller-scale or specialized applications, a flat die pellet mill is also available.

RICHI pellet making machine for cattle feed is compatible with a wide range of raw materials, including corn, soybean meal, wheat bran, alfalfa, and other roughage. Its simple operation and easy maintenance make it ideal for farmers who want reliable, high-quality pellets.

We also provides complete feed processing solutions, including crushing, mixing, pelletizing, cooling, screening, and packaging, for customers seeking turnkey feed mill projects.

Video Showcase Of Cattle Feed Making Machine

The video showcase of the cattle feed pellet machine provides a clear and practical view of how the equipment operates in real production conditions. By watching the full process, users can understand the machine’s efficiency, pellet quality, and operational stability, helping them choose the most suitable solution for their farm or feed mill.

RICHI MACHINERY

Core Components of Cattle Feed Pellet Machine

The pellet cattle feed machine consists of several core components, each designed to ensure high efficiency, stable operation, and excellent pellet quality. Understanding these key parts helps users evaluate the machine’s performance and suitability for their feed production needs.

Advantages of RICHI Pellet Machine For Cattle Feed

The RICHI cattle feed pellet machine offers advanced technology, reliable performance, and high-quality pellet production, designed specifically for cattle feed requirements. Its innovative design ensures energy efficiency, durability, and consistent pellet quality, helping farmers improve feed utilization, reduce waste, and enhance cattle growth.

High-Quality Pellets

Optimized design ensures maximum output with lower energy consumption, reducing overall production costs.

Advanced Technology

Equipped with high-precision ring dies, forced feeding system, and efficient conditioners, ensuring smooth operation, high pellet output, and energy savings.

Durable and Reliable

Built with robust components such as high-strength stainless steel ring dies and Siemens motors, providing long service life and stable performance under continuous operation.

Raw Material Adaptability

Can process a wide range of ingredients, including corn, soybean meal, wheat bran, rice husk, and other agricultural by-products, enabling efficient use of local raw materials.

Flexible Capacity & User-Friendly

Suitable for various farm or feed mill scales. Modular design and intuitive controls make it easy to operate, maintain, and expand according to production needs.

Models of Cattle Feed Pellet Machine For Sale

RICHI Machinery provides multiple pellet machine for cattle feed options suitable for various farm sizes and production needs. Whether used in small farms or commercial feed mills, every model ensures reliable performance, high efficiency, and long service life.

SZLH250 Cow Feed Pellet Machine

- Capacity: 1-2T/H

- Main motor power: 22kw

- Feeder power: 1.1kW

- Conditioner power: 1.5kw

- Price range: 7,000 -10,000$

SZLH320 Cattle Feed Pellet Mill

- Capacity: 3-4T/H

- Main motor power: 37kw

- Feeder power: 1.5kW

- Conditioner power: 2.2kw

- Price range: 15,000 -20,000$

SZLH350 Cattle Feed Pellet Machine

- Capacity: 5-7T/H

- Main motor power: 55kw

- Feeder power: 1.5kW

- Conditioner power: 3kw

- Price range: 20,000 -30,000$

SZLH420 Cattle Feed Pellet Making Machine

- Capacity: 8-12T/H

- Main motor power: 110kw

- Feeder power: 1.5kW

- Conditioner power: 7.5kw

- Price range: 30,000 -40,000$

SZLH508 Cattle Feed Mill Machine

- Capacity: 10-18T/H

- Main motor power: 160kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 40,000 -60,000$

SZLH558 Pellet Machine For Cattle Feed

- Capacity: 15-25T/H

- Main motor power: 180kw /220kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 60,000 -70,000$

SZLH678 Pellet Cattle Feed Machine

- Capacity: 20-30T/H

- Main motor power: 220kw /250kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 70,000 -80,000$

SZLH768 Cattle Feed Pellet Machine

- Capacity: 25-40 T/H

- Main motor power: 250kw /280kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 80,000 -90,000$

RICHI MACHINERY

How to Choose the Right Model?

Choosing the right cattle feed pellet machine model is essential to ensure efficient production, stable operation, and long-term cost control. After reviewing the technical parameters, customers should focus on actual production needs, raw material characteristics, and future expansion plans. The following factors can help you select the most suitable model.

RICHI Cattle Feed Pellet Machine For Sale Global

RICHI cattle feed pellet machines are backed by over 30 years of experience in feed processing machinery manufacturing. Our equipment has been delivered to customers in more than 140 countries and regions, with each project tailored to local raw materials and production requirements. These global projects demonstrate the reliable performance, adaptability, and efficiency of RICHI pellet mills in diverse production environments, helping farmers and feed mills achieve stable and high-quality feed production worldwide.

1-2T/H Cattle Pellet Machine For Sale Uzbekistan

- Country: Uzbekistan

- Primary Raw Materials: Corn, wheat bran, cottonseed meal, soybean meal

- Background: A dairy farm in Uzbekistan sought a compact cattle feed making machine to improve feed utilization and reduce waste. The feed includes medium fiber content suitable for medium-scale operations. The project aimed for low cattle feed pellet machine price investment, easy operation, and stable output.

2-3T/H Cattle Feed Pellet Machine For Sale Tanzania

- Country: Tanzania

- Primary Raw Materials: Cornmeal, crop straw, soybean cake, hay

- Background: An East African cattle farm required a small-scale feed processing line to support local dairy and beef production. The feed contains high fiber content, so a high-torque ring die pellet machine was chosen to ensure stable pellet formation and efficient feed utilization. The goal was to provide reliable feed for the farm while reducing dependency on external suppliers.

5-6T/H Nigeria Pellet Machine For Cattle Feed

- Country: Nigeria

- Primary Raw Materials: Corn, soybean meal, wheat bran, sugarcane bagasse

- Background: A commercial dairy farm in Nigeria needed a medium-capacity feed pellet machine to provide balanced nutrition for cattle. The project included multiple feed recipes, requiring the animal feed granulator to adapt to different ingredient combinations. The focus was on stable production, high pellet quality, and flexibility for various feed formulations.

6-8T/H Cattle Feed Pellet Mill Machine in Romania

- Country: Romania

- Primary Raw Materials: Corn, wheat bran, alfalfa, soybean meal

- Background: An industrial ruminant feed pellet production line in Eastern Europe required a medium-to-large feed pellet machine with higher automation. The feed included high-protein ingredients for both dairy and beef cattle. The project aimed to improve operational efficiency, reduce labor costs, and ensure consistent pellet quality for large-scale production.

8T/H Cattle Feed Pellet Mill For Sale India

- Country: India

- Primary Raw Materials: Corn, wheat bran, soybean meal, grass powder

- Background: A animal feed production line in India required a high-capacity feed pellet machine to meet the feed needs for a wide-scale cattle operation. The project emphasized continuous operation, high output, and automation to provide stable feed supply throughout the year. The feed line needed to handle multiple recipes efficiently.

10T/H Cattle Feed Pellet Machine For Sale South Africa

- Country: South Africa

- Primary Raw Materials: Corn, soybean meal, wheat bran, alfalfa, forage powder

- Background: A commercial cattle feed mill in South Africa required a fully automated, large-capacity feed pellet machine. The feed included high-protein and high-fiber ingredients. The project aimed to establish a continuous, reliable, and large-scale feed production system capable of meeting all nutritional requirements for livestock.

Benefits of Cattle Feed Pellets

Cattle feed pellets have become the preferred choice for modern cattle farms due to their convenience, efficiency, and nutritional consistency. By converting loose feed ingredients into uniform pellets, farmers can achieve better feed utilization, reduce waste, and provide balanced nutrition to their livestock. Here are the key benefits of cattle feed pellets and why RICHI cattle feed pellet machines are the ideal solution.

Uniform Nutrition and Improved Feed Efficiency

Pellets are consistent in size and density, ensuring that every animal receives the same level of nutrition in each bite. This uniformity enhances digestibility and feed conversion rates, promoting healthier growth and better overall performance.

Easy Storage, Transport, and Reduced Waste

Pellets are compact and durable, making them easier to store and transport compared to loose or mash feed. Their dense form reduces spoilage and dust, minimizing feed loss and maintaining feed quality throughout handling and delivery.

Complete and Balanced Diet in Every Pellet

Pellets can incorporate grains, protein sources, vitamins, and minerals into a single feed form, ensuring livestock receive a balanced diet with every pellet. This simplifies feeding management and supports optimal growth, health, and production.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 140 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

Tailored animal feed mill equipment for sale global to meet your farm or feed mill’s specific needs.

Modern Workshop

State-of-the-art manufacturing facilities ensure precision, durability, and consistent quality.

On-site Installation

Professional engineers provide installation services on-site for smooth start-up.

Information Sharing

Keep clients updated with technical knowledge, process improvements, and industry trends.

On-the-spot Training

Hands-on training ensures your staff can operate and maintain equipment efficiently.

After-Sales Service

Timely support and maintenance services to minimize downtime and maximize production efficiency.

Frequently Asked Questions About Cattle Feed Pellet Machine

Can a single pellet machine produce different feed formulas?

+

Yes, a single cattle feed pellet machine can produce multiple feed formulas for different types of livestock. By adjusting the pellet diameter, density, and raw material composition, operators can customize pellets for various growth stages and nutritional requirements. For example, the same machine can produce high-protein pellets for dairy cows, fiber-rich pellets for beef cattle, and specialized formulas for pigs, chickens, or sheep.

Additionally, with modular design and flexible die sizes, the machine can quickly switch between different feed recipes, making it a versatile and cost-effective investment for farms or feed mills with mixed livestock. Proper operation and careful control of moisture, temperature, and compression ensure consistent pellet quality across all formulas.

I mainly raise dairy and beef cattle, and also have pigs, chickens, and sheep. Can I use this machine to produce feed suitable for these other animals?

+

Yes, RICHI cow feed pellet making machines are highly versatile and can produce feed for a variety of livestock. Besides dairy and beef cattle, with proper adjustment of pellet diameter, density, and feed formulation, you can produce high-quality feed suitable for pigs, chickens, and sheep. For instance, you can create smaller, softer pellets for poultry, moderate-fiber pellets for pigs, or high-fiber, larger pellets for sheep.

This flexibility allows a single machine to serve multiple animals on the same farm, saving investment costs while ensuring consistent pellet quality for all species. Proper control of moisture, temperature, and compression ensures that each type of feed meets the specific nutritional requirements of the animals.

I run a farm with 2,000 cattle. Which pellet mill should I choose?

+

To select the right pellet mill, it is important to first calculate your daily feed requirement. Each cow consumes 6 kg of feed per day, a farm with 2,000 cattle would need:

- 6 kg ×2,000=12,000 kg/day (12 tons/day)

If the pellet mill operates 6–8 hours per day, the required production capacity would be:

- 12,000 kg/day ÷ 6=2,000 kg/hour (2 T/H)

- 12,000 kg/day ÷ 8 hours/day=1,500 kg/hour (1.5 T/H)

Therefore, a pellet mill with a capacity of 1.5–2 T/H is sufficient to meet the daily feed needs of 2,000 cattle. For farms producing multiple feed formulas or handling larger volumes, our ring die pellet mill is recommended for its stable operation, high efficiency, and ability to process a variety of raw materials.

How much does a Cattle Feed Pellet Machine cost?

+

The cattle feed pellet machine price typically ranges from USD 7,000 to USD 85,000, depending mainly on production capacity, configuration level, and application scale.

In general, smaller machines or systems with simpler configurations are more affordable. These models are often designed for individual farms or small feed operations and focus on basic pelletizing functions with manual or semi-automatic control.

As production capacity increases and the system becomes more integrated, the overall investment rises accordingly. Machines designed for commercial or industrial feed production usually feature stronger structures, higher torque, more durable ring dies, and better automation, which contributes to a higher price but also ensures stable output and long-term reliability.

In addition, the final cost may vary based on whether auxiliary equipment such as crushers, mixers, coolers, or packaging units is included, as well as factors like customization, installation, and technical support. Choosing the right configuration based on actual production needs is key to achieving a balanced investment and operating efficiency.