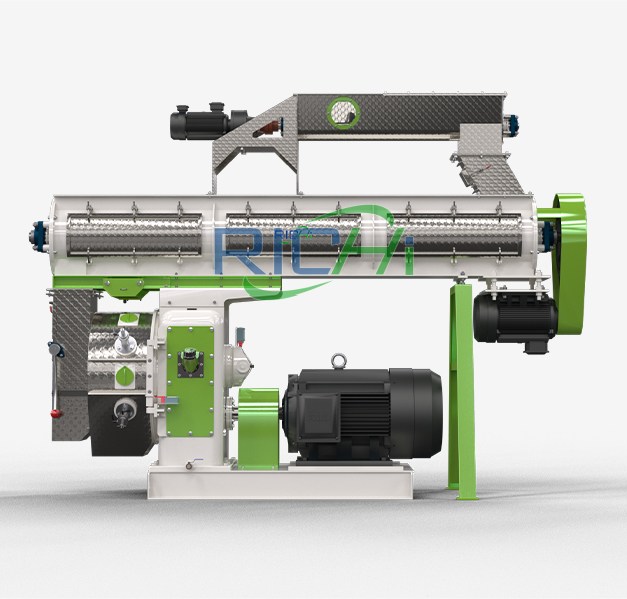

Chicken Feed Pellet Machine For Sale

Chicken feed pellet machine is designed to produce uniform, high-quality feed pellets for chickens. It provides stable performance, easy operation, and flexible feed formulations, making it ideal for poultry farms and feed producers.

Introduction Of RICHI Chicken Feed Pellet Machine For Sale

A chicken feed pellet machine is a specialized machine designed to process raw feed materials into uniform pellets for chickens. It is widely used in the production of chicken, broiler, and layer feeds, improving feed consistency and feeding efficiency.

The chicken pellet maker converts mixed feed materials into uniform pellets through a mechanical compression process. After the raw materials are evenly mixed, they are fed into the pelletizing chamber, where rollers press the materials through a precision-engineered die. Under controlled pressure and temperature, the feed is formed into dense pellets with consistent size and structure.

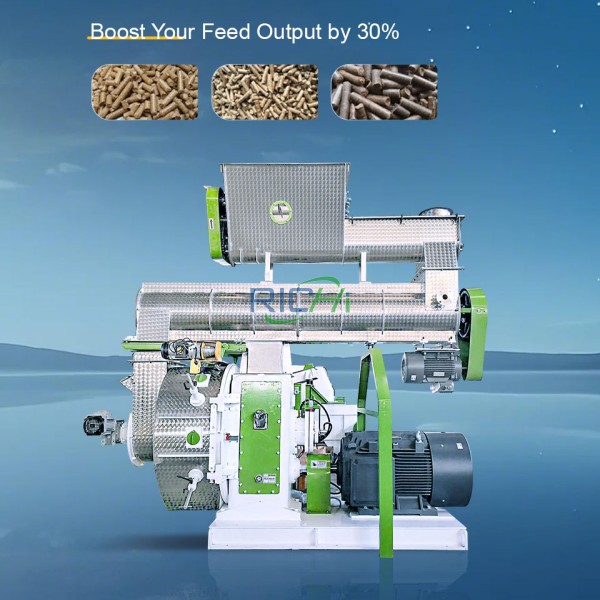

RICHI chicken feed pellet machine for sale is available in a wide range of production capacities to meet different requirements. Depending on the model and feed formulation, the output typically ranges from 1–40T/H, covering small-scale feed processing to large commercial chicken feed production.

- Production Capacity: 1-40T/H

- Machine type: Ring Die Feed Pellet Machine

- Pellet Size: Typically 2–6 mm (Pellet size can be customized according to chicken growth stages)

Working Video Of Chicken Feed Pellet Machine

This video demonstrates the chicken feed pellet machine for sale running smoothly, producing uniform chicken feed pellets with high efficiency. You can observe the entire pelletizing process, from raw material feeding to finished pellet output, highlighting its stable operation, consistent pellet quality, and ease of use. Watching the machine in operation helps you better understand its performance and suitability for your chicken feed production needs.

Core Components of Chicken Feed Pellet Machine For Sale

The et machine for chicken feed consists of several key components that work together to ensure efficient and high-quality chicken feed production. Each component is carefully designed to optimize pellet formation, durability, and ease of operation.

Feeding System

Includes automatic feed hopper and screw feeder, ensuring uniform feeding and consistent pellet quality.

Stainless Steel Body

Constructed with high-quality 304 stainless steel, ensuring durability, corrosion resistance, and easy cleaning.

Conditioner

The conditioner mixes raw materials before pelletizing, improving pellet density, durability, and feed digestibility.

Ring Die

The core of pellet formation, ensures uniform, dense pellets with high durability.

Siemens Motor

Provides stable power for the whole machine, optimized for energy efficiency and long service life.

Control Panel

PLC or electric control panel for easy operation, monitoring, and safety protection.

Models of RICHI Chicken Feed Pellet Machine For Sale

RICHI Machinery offers a wide range of chicken feed pellet machine models to meet the needs of medium to large chicken farms and commercial chicken feed mills of different scales. Each machine is engineered for stable operation, high-quality pellet output, and easy maintenance. With flexible capacity options ranging from 1–40T/H, our equipment can process various raw materials and chicken feed formulas, ensuring efficient and cost-effective chicken feed production.

SZLH250 Small Chicken Feed Pellet Machine

- Capacity: 1-2T/H

- Main motor power: 22kw

- Feeder power: 1.1kW

- Conditioner power: 1.5kw

SZLH320 Pellet Machine For Chicken Feed

- Capacity: 3-4T/H

- Main motor power: 37kw

- Feeder power: 1.5kW

- Conditioner power: 2.2kw

SZLH350 Chicken Pellet Machine

- Capacity: 5-6T/H

- Main motor power: 55kw

- Feeder power: 1.5kW

- Conditioner power: 3kw

SZLH420 Chicken Feed Pellet Machine For Sale

- Capacity: 10T/H

- Main motor power: 110kw

- Feeder power: 1.5kW

- Conditioner power: 7.5kw

SZLH508 Chicken Pellet Making Machine

- Capacity: 15T/H

- Main motor power: 160kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

SZLH558 Chicken Feed Pellet Maker

- Capacity: 20T/H

- Main motor power: 185kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

SZLH678 Chicken Feed Pellet Making Machine

- Capacity: 30T/H

- Main motor power: 250kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

SZLH768 Chicken Feed Pellet Machine For Sale

- Capacity: 40T/H

- Main motor power: 315kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

How to Choose the Right Chicken Feed Pellet Machine For Sale?

Selecting the right chicken feed pellet machine is crucial for ensuring efficient production, high-quality chicken feed pellets, and a strong return on investment. Here are the key factors to consider:

1

Production Capacity: First, clarify your required output per hour. If the chicken feed pellet machine capacity is too small, it may not meet daily feed demand, leading to long operating hours and increased machine wear.

2

Feed Formula & Raw Materials: Chicken feed pellet machines are mainly used for corn, soybean meal, wheat bran, and premix-based formulas. Make sure the machine matches your feed formulation.

3

Pellet Size Requirement: When choosing a chicken feed pellet machine, it is important to confirm whether the pellet diameter can be adjusted to suit different growth stages of poultry.

4

Budget & Expansion Possibility: If your budget is limited or you plan to expand later, choosing a standalone chicken feed pellet machine is more flexible.

5

Power Supply & Installation Conditions: Check local voltage and power limits to ensure the pellet machine can operate stably on your site.

Chicken Feed Pellet Machine For Sale global

With over 30 years of industry experience, RICHI has successfully supplied chicken feed pellet machines and complete chicken feed production projects to more than 140 countries worldwide. These projects clearly demonstrate the versatility, reliability, and efficiency of our equipment in real production environments. From medium to large chicken farms to commercial chicken feed mills, RICHI machines consistently deliver high-quality chicken feed pellets, stable operation, and cost-effective feed production solutions across different production scales.

Benefits of Chicken Feed Pellets

With the growing demand for efficient and high-quality poultry nutrition, chicken feed pellets have become the preferred feeding form for modern chicken farming. RICHI chicken feed pellet machine for sale plays a key role in producing uniform, nutritionally balanced pellets that improve feed intake, reduce waste, and enhance overall feeding efficiency. By converting raw feed materials into dense, consistent pellets, pelletized feed supports healthier growth and better performance in broilers, layers, and breeder chickens.

Uniform Nutrition

Each pellet contains the exact proportions of protein, vitamins, and minerals, ensuring every bite delivers consistent nutrition.

Reduced Feed Waste

Pellets minimize spillage and selective feeding, improving feed utilization and lowering costs.

Better Feed Conversion

Uniform, digestible pellets allow chicken to gain more weight or produce more eggs from the same feed.

Convenient Handling and Storage

Pellets are easy to transport, store, and feed, reducing labor and improving farm efficiency.

Advantages of RICHI Chicken Feed Pellet Machine For Sale

The RICHI chicken feed machine combines advanced technology, high-quality materials, and user-friendly design to deliver reliable and efficient feed production. With superior pellet consistency, low energy consumption, and broad raw material adaptability, our machines are ideal for poultry farms and commercial feed mills seeking stable operation, reduced maintenance, and cost-effective feed production.

Advanced Pelletizing Technology

Utilizes precise pressure and temperature control to produce dense, uniform pellets that enhance feed efficiency and reduce waste.

Wide Raw Material Compatibility

Handles corn, soybean meal, wheat bran, fish meal, and other additives, allowing flexible feed formulations.

Stable Operation with Low Energy Consumption

Optimized design reduces vibration and energy usage while maintaining high output efficiency.

Uniform and Durable Pellets

Produces dense pellets with consistent size, reducing feed waste and improving digestibility.

Modular Design for Easy Maintenance

Modular components allow quick assembly, disassembly, and replacement, simplifying routine maintenance and reducing downtime.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 140 countries and regions worldwide. Our poultry feed mill machines are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

Tailored feed processing machinery to meet your specific needs.

Modern Workshop

State-of-the-art manufacturing facilities ensure precision, durability, and consistent quality.

On-site Installation

Professional engineers provide installation services on-site for smooth start-up.

Information Sharing

Keep clients updated with technical knowledge, process improvements, and industry trends.

On-the-spot Training

Hands-on training ensures your staff can operate and maintain equipment efficiently.

After-Sales Service

Timely support and maintenance services to minimize downtime and maximize production efficiency.

Frequently Asked Questions About Chicken Feed Pellet Machine For Sale

Does the feed mill machine only produce one type of feed? Can it handle different chicken species?

+

No. A chicken feed pellet machine for sale is designed to be highly versatile rather than limited to a single feed type. By adjusting feed formulations, pellet diameters, and processing parameters, the machine can produce a wide range of chicken feeds, including broiler starter, grower and finisher feed, layer feed, breeder feed.

This flexibility allows one production line to meet the nutritional requirements of different growth stages, making it suitable for diversified poultry farms and commercial feed mills supplying multiple markets.

Could you provide some chicken feed formulations?

+

Yes. Below are several reference feed formulations for different growth stages. These formulas are for general guidance only and can be adjusted according to local raw material availability, feed standards, and nutritional targets.

- Broiler Starter Feed (0–3 weeks): Corn 50%-55%, Soybean meal 30–35%, Fish meal 5–7%, Wheat bran 3–5%, Vegetable oil 2–3%, Dicalcium phosphate + limestone 2–3%, Premix (vitamins & minerals) 1%

- Broiler Grower Finisher Feed (4–6 weeks): Corn 55–60%, Soybean meal 25–30%, Wheat bran 5–8%, Fish meal 3–5%, Vegetable oil 2–3%, Mineral additives + premix 2–3%

- Layer Feed (Laying Period): Corn: 50–55%, Soybean meal: 18–22%, Wheat bran: 5–8%, Limestone (calcium source): 8–10%, Dicalcium phosphate: 1–2%, Premix (vitamins & minerals): 1%

How much does it cost to invest in a 2T/H chicken feed pellet machine for sale?

+

In general, the standalone chicken feed pellet machine for sale with a capacity of around 5 tons per hour is priced between $7,000 to 10,000, depending on the machine model, configuration, and technical specifications.

If your project requires not only the pellet mill but also a complete chicken feed production line (including crushing, mixing, cooling, conveying, electrical control, and optional packaging systems), the total investment will be higher. In this case, the overall project cost typically ranges from USD 10,000 to 50,000, depending on the production capacity, automation level, and customized requirements.

Can a poultry feed pellet mill project for chicken be scaled up in the future?

+

Yes. A chicken feed manufacturing plant can be scaled up in the future if it is properly planned from the beginning. Most modern poultry feed pellet mills are designed with modular and expandable structures, allowing additional equipment or higher-capacity machines to be added as production demand increases.

In practice, scale-up options may include upgrading to a larger pellet mill model, adding parallel pelletizing lines, increasing raw material handling and mixing capacity, or integrating automated conveying and packaging systems. With sufficient space reserved in the plant layout and compatible electrical and control systems, a small or medium poultry pellet mill can be smoothly expanded into a higher-capacity commercial feed production facility.

Can the machine produce specialized feeds like breeder or vitamin-enriched layer feed?

+

Yes. The chicken feed pellet machine for sale is capable of producing specialized feeds such as breeder feed, vitamin-enriched layer feed, or other functional feeds. By adjusting the feed formulations, pellet size, and processing parameters, the machine can meet the specific nutritional requirements of different poultry types and growth stages.

This flexibility allows poultry farms and commercial feed mills to produce a wide variety of feeds with a single machine, ensuring optimal growth performance, egg quality, and overall flock health.