Chicken Feed Pellet Making Machine

With the development of the chicken farming industry towards standardization and large-scale operations, the chicken feed pellet making machine has become the core equipment for improving farming efficiency and ensuring flock health.

Production Of Chicken Feed Pellet Making Machine

RICHI Machinery not only provides stable and reliable chicken feed pellet making machine but also customizes feed production solutions based on your raw material and production requirements, which ensures your purchase and operation are carefree.

RICHI Chicken Feed Pellet Making Machine For Sale

RICHI Chicken Feed Pellet Making Machine is a feed processing equipment specifically designed for poultry farming. It mixes raw materials such as corn, soybean meal, bran, fish meal, vitamins, and minerals according to scientific formulas. Through processes of extrusion and conditioning, it produces uniformly sized, hard pellet feed. This equipment is crucial for chicken feed mills to enhance efficiency and reduce costs. The high density of pellet feed resists moisture absorption and mold growth, which makes it last longer in storage than powdered feed. It’s also easier to transport, which saves poultry farmers money on storage and logistics. Moreover, the uniform size and moderate density of these pellets match chickens’ feeding habits, which can effectively prevent selective eating and improve feed utilization.

In terms of application scenarios, suitable models can be provided for operations ranging from small-scale backyard to modern chicken farms. RICHI offers customized chicken feed pellet making machines with production capacities from 1 to 45 tons per hour to meet diverse needs. RICHI chicken feed pellet machine can produce not only for chickens but also for various animals such as chickens, ducks, pigs, cattle, and sheep.

RICHI MACHINERY

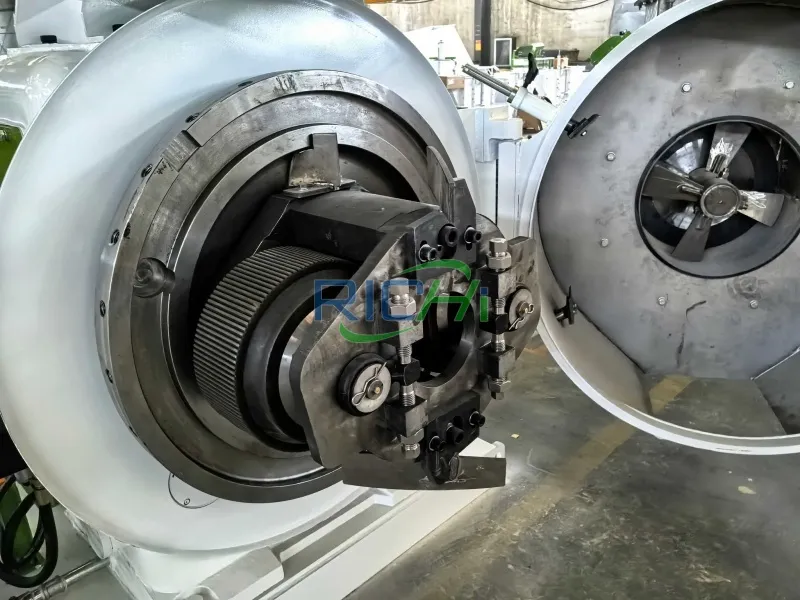

Core Components

The stable operation and pellet quality of chicken feed pellet making machines depend on the cooperation of core components. Each part plays an irreplaceable role and is designed to meet the processing requirements of poultry feed.

Advantages of Chicken Feed

For chickens of different ages and breeds, high-quality feed have irreplaceable advantages.

Nutritionally Balanced

Compared to the single-ingredient powder prepared by individual farmers, our chicken feed formula is nutritionally balanced. This prevents nutritional imbalances caused by selective eating among the flock, which ensures that every chicken receives sufficient protein, vitamins, and minerals.

Convenient for Storage

During the pelleting process, some moisture will be lost, thus resulting in a lower moisture content in the pellet feed compared to the material before pelleting. This not only saves storage space but also prevents moisture absorption. Additionally, loose feed is easy to generate dust. After being produced into pellets, dust pollution will be reduced, which lead to a cleaner farming environment.

Precise Feeding

Pelleted feed offers convenient measurement, which enables precise control of feed intake whether administered manually by small-scale individual farmers or through automated feeding systems in large-scale operations. This prevents cost wastage from overfeeding or growth impairment caused by insufficient intake.

Enhancing Digestibility and Absorption

Under high temperature and high pressure, chicken feed maker machine not only effectively eliminate harmful pathogens such as E. coli but also promote starch gelatinization, which is easier for chickens to digest and absorb.

Working Principle

The production process of a chicken feed pellet making machine can be divided into four key steps: feeding, conditioning, pelleting and cutting. Each step directly impacts the quality and yield of the final product.

- Feeding: We need to add the mixing powder according to the chicken feed formula into the hopper. Under the force of gravity and the screw conveyor, the powder enters the pelleting chamber. The chicken feed pellet mill employs intelligent control to automatically adjust the feeding rate, which ensures that the feed powder is mixed in the correct proportions.

- Conditioning: The add of steam not only makes the raw materials easier to form but also activates their nutritional components, which improves the digestibility and absorption rate of chicken feed. At the same time, it effectively kills harmful microorganisms, which makes the chicken feed safer and more nutritious. The optimal conditions for chicken feed pelleting are a moisture content of 16%-18% and a temperature of 75°C-85°C.

- Pelleting: The raw materials after tempering are sent into the most important pelletizing chamber. The core components are the ring die and the press rollers inside it. Under the squeeze of the rollers and ring die, the raw materials are compressed and forced through the small holes in the ring die, which forms high-density feed pellets.

- Cutting: After being extruded through the small holes in the ring die, the pellet feed is cut into the desired length by the cutting blades mounted on the outer side of the ring die. By adjusting the position and rotational speed of the cutting blades, the length of each chicken feed pellet can be precisely controlled.

Features of Chicken Feed Pellet Making Machine

We understand that selecting a feed pellet machine is not merely choosing equipment, but selecting a long-term partner. Therefore, we pursue perfection in every detail, which reflects our deep understanding of customer value.

High Output And High Efficiency

Wide Applicability

RICHI chicken feed pellet machine for sale can produce not only for chickens but also for various animals such as chickens, ducks, pigs, cattle, and sheep.

Flexible Raw Material Utilization

Conventional ingredients like corn and soybean meal can be mixed with specialty materials such as straw powder, insect protein, and fermented feed for pellet production. This not only reduces reliance on commercial feed but also meets the demands of ecological and organic farming practices.

Reducing Farming Costs

The uniformly sized pellets produced by the chicken feed pellet mill prevent selective feeding among flocks, which can reduce waste by 15%-20%. At the same time, the high density of the pellets minimizes losses during storage and transportation, and the long-term use can reduce feed cost expenditures.

Flexible and Simple Operation

Fully automated from raw material processing to final packaging requires only 1-2 operators, which greatly reduces labor costs and boosts productivity.

Chicken Feed Pellet Making Machine Parameter and Price

RICHI offers a range of feed pellet machine models to meet the needs of farms of all sizes, from family farming operations to large-scale breeding bases.

SZLH250 chicken pellet making machine

- Capacity: 1-2T/H

- Main motor power: 22kw

- Conditioner power: 1.5kw

- Ring die diameter: 250mm

- Final pellet diameter: 2-12mm

- Price range: 7,000 -10,000$

SZLH320 chicken pellet making machine

- Capacity: 3-4T/H

- Main motor power: 37kw

- Conditioner power: 2.2kw

- Ring die diameter: 320mm

- Final pellet diameter: 2-12mm

- Price range: 15,000 -20,000$

SZLH350 chicken pellet making machine

- Capacity: 5-7T/H

- Main motor power: 55kw

- Conditioner power: 3kw

- Ring die diameter: 350mm

- Final pellet diameter: 2-12mm

- Price range: 20,000 -30,000$

SZLH420 chicken pellet making machine

- Capacity: 8-12T/H

- Main motor power: 110kw

- Conditioner power: 7.5kw

- Ring die diameter: 420mm

- Final pellet diameter: 2-12mm

- Price range: 30,000 -40,000$

SZLH508 chicken feed pellet machine

- Capacity: 10-18T/H

- Main motor power: 160kw

- Conditioner power: 11kw

- Ring die diameter: 508mm

- Final pellet diameter: 2-12mm

- Price range: 40,000 -60,000$

SZLH558 chicken feed pellet machine

- Capacity: 15-25T/H

- Main motor power: 180kw /220kw

- Conditioner power: 11kw

- Ring die diameter: 558mm

- Final pellet diameter: 2-12mm

- Price range: 60,000 -70,000$

SZLH678 chicken pellet making machine

- Capacity: 20-30T/H

- Main motor power: 220kw /250kw

- Conditioner power: 11kw

- Ring die diameter: 678mm

- Final pellet diameter: 2-12mm

- Price range: 70,000 -80,000$

SZLH768 chicken pellet making machine

- Capacity: 25-40 T/H

- Main motor power: 250kw /280kw

- Conditioner power: 11kw

- Ring die diameter: 768mm

- Final pellet diameter: 2-12mm

- Price range: 80,000 -90,000$

SZLH858 chicken pellet making machine

- Capacity: 28-45 T/H

- Main motor power: 315kw /355kw

- Conditioner power: 15kw

- Ring die diameter: 858mm

- Final pellet diameter: 2-12mm

- Price range: 90,000 -100,000$

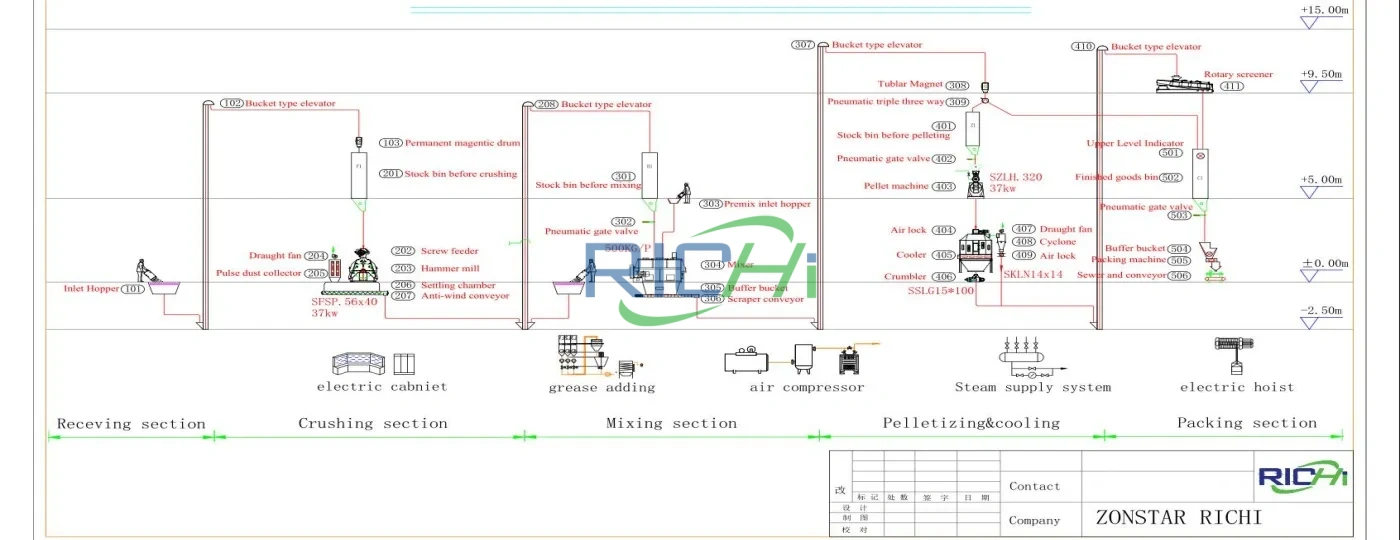

Chicken Feed Pellet Production Line

RICHI chicken feed pellet making machines offer capacities ranging from 1 ton per hour to 40 tons per hour, which can be used for chicken feed pellet production lines with capacities of 0.7-100 tons per hour. Below is the process flow for a chicken feed manufacturing plant with a capacity of 3-4 tons per hour.

1.Crushing

Primary Equipment: Feed Crusher

First of all, it is necessary to crush the food materials which are prepared according to the formula. This not only can ensure the pelleting effect of the feed pellet press, but also can make the raw materials easier to digest and absorb by the animals.

2.Mixing

Primary Equipment: Feed Mixer

After crushing, we need a feed mixer to mix the crushed raw materials evenly. It can make the made feed pellets nutritionally balanced, and promote the healthy growth of animals.

3. Pelleting

Primary Equipment: Animal Feed Mill Equipment

Pelleting machine is the key equipment of the feed production line, which directly determines the output of the production line and the quality of the pellets. Therefore, the equipment selection and operation of this step must be emphasized.

4. Cooling

Primary Equipment: Counter Flow Cooler

The just-made feed pellets temperature and humidity are very high, can not be immediately bagged, easy to cause pellets cracked. Therefore, it is necessary to utilize the cooling machine to cool the feed pellets to room temperature before packing.

5.Sifting

Primary Equipment: Powder Cleaning Machine

After cooling, the mixed material is screened to remove clumps, which ensures the quality of the compound feed.

6. Packing

Primary Equipment: Automatic Packing System

Customers can choose packing method according to their needs. Most customers choose to use automatic packing machine to pack the feed pellets in bags.

Cases For Chicken Feed Pellet Making Machine

RICHI chicken feed pellet making machines have gained recognition from customers worldwide.

5-6T/H Chicken Feed Pellet Making Machine

- Country:Zimbabwe

- Date:2023

- Main Raw Material: corn, barley, sorghum, oils, soybean meal.

- Particle size: 1–12 mm ( 1.5–4 mm for chickens. )

- Background: There exists a gap in the local chicken feed production market, and there is a scarcity of suppliers specializing in providing high-quality and reasonably priced commercial pellet feed for small and medium-sized livestock farmers. This project was initiated by a social enterprise.

10T/H Chicken Feed Pellet Making Machine

- Country:Tanzania

- Date: 2024

- Main Raw Material: Soybeans, corn, wheat, other grains, etc.

- Particle size: 1–12 mm ( 1.5–4 mm for chickens. )

- Background: The company has decided to invest in building a medium-sized and high-efficiency poultry feed mill. The goals are to control feed quality, reduce reliance on imported feed, and establish a sustainable supply chain to support its rapidly expanding broiler and layer farms.

10-15T/H Chicken Feed Pellet Making Machine

- Country: Uzbekistan

- Date: 2024

- Main Raw Materials: Corn, wheat, soybean meal, sorghum, cottonseed meal, etc.

- Particle size: 1–12 mm ( 1.5–4 mm for chickens. )

- Background: The company is a robust integrated agricultural enterprise with operations covering grain cultivation and poultry farming. To further enhance its industrial chain, it has decided to expand into the field of processing chicken feed, so as to reduce reliance on external suppliers and lower farming costs.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.

FAQ About Chicken Feed Pellet Making Machine

What are the common formulations for chicken feed pellets?

+

Below are some common formulations for chicken feed pellets for your reference. The specific formulation depends on your actual requirements. If you are unsure about which raw materials to choose, welcome to consult us and we will provide professional advice based on your needs.

For broiler feed formulation reference:

- 0-5 weeks of age: 6% fish meal, 24.7% soybean meal, 3% wheat bran, 61.6% corn, 1.5% wheat flour, 3.2% additives

- Over 5 weeks of age: 8% fish meal, 19% soybean meal, 2.5% wheat bran, 67% corn, 0.5% oilseed meal, 3% additives

For laying hen feed formulation reference:

- Chicks (1-60 days): Corn 62%, Bran 10%, Soybean Meal 17%, Fish Meal 9%, Bone Meal 2%.

- Chicks (61-120 days): Corn 55%, Bran 20%, Soybean Meal 7%, Cottonseed Meal 5%, Rapeseed Meal 5%, Fish Meal 5%, Bone Meal 2%, Shellfish Meal 1%.

- Feed Formula for Young Laying Hens (61–120 days): Corn 55%, Bran 20%, Soybean Meal 7%, Cottonseed Meal 5%, Rapeseed Meal 5%, Fish Meal 5%, Bone Meal 2%, Shellfish Meal 1%.

Should the diameter of pellet feed be adjusted for chickens of different ages?

+

Yes. Chicks (0-4 weeks old) have delicate digestive systems, so pellets with a diameter of 2-3mm are recommended for easy consumption and digestion. For growing chickens (5-10 weeks old), pellets with a diameter of 3-4mm are suitable. Adult laying hens or broilers are suitable for pellets with a diameter of 4-6mm, which can meet feeding efficiency and avoid waste. The RICHI chicken feed pellet making machine allows for diameter adjustment by simply swapping ring dies with different apertures, which is easy to operate.