EFB Pellet Machine

The EFB Pellet Machine is an environmentally friendly machinery, which is specifically designed to convert EFB into high-density, uniformly shaped biomass fuel pellets.

Core Definitions of EFB Pellet Machine

EFB pellet machine is a granulation machine specifically designed to address the issue of waste from palm oil mills.

EFB stands for Empty Fruit Bunch, which is the main agricultural waste produced by palm oil mills after the extraction of palm oil. These waste materials are difficult to process, occupy a lot of space when piled up and they are prone to causing environmental problems. Moreover, EFB fibers are long and have a loose texture, which is difficult to utilize in their natural state.

However, the EFB pellet machine is not only a machine but also a crucial component in realizing the circular economy of the palm oil industry. Through specialized technology, it transforms agricultural waste into economically valuable green energy and products, which greatly reduces environmental burdens and creates new sources of income. This holds immense significance for palm oil-producing nations, where the EFB pellet machine brings substantial economic and environmental benefits.

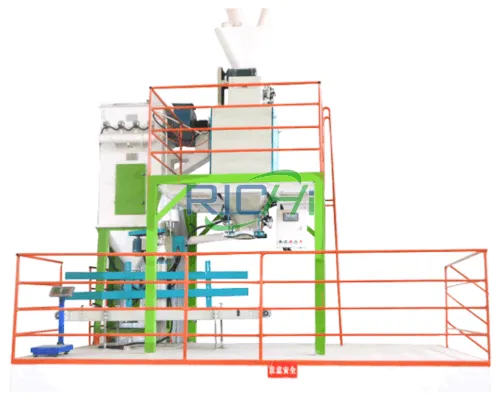

RICHI Machinery’s EFB Pellet Machine features advanced design and production configuration, with compact structure and excellent performance. In addition to processing EFB pellets, this EFB pellet machine can also pelletize materials that are difficult to process with low adhesion rates, such as rice husks, sunflower seed shells, peanut shells and stems, bark, and other biomass waste. Additionally, we can customize EFB pellet plant to meet your specific production requirements.

How Does a EFB Pellet Machine Work?

The working principle of the EFB pellet machine involves the physical process of high-temperature, high-pressure compression to compulsorily reshape loose and unformed EFB fibers into high-density, uniformly shaped solid fuel pellets. The entire conversion process can be divided into four stages.

- Feeding: The crushed EFB fibers are uniformly fed into the pelleting chamber through the feeder.

- Conditioning: During this process, steam is injected to condition the fibers, which makes them softer and more flexible. Simultaneously, the temperature is raised to facilitate subsequent forming.

- Forming: Under the powerful pressure of the press rollers, fibers are forcibly squeezed through the cylindrical channels of the ring die. During this process, the material becomes extremely dense.

- Cutting: As the compressed material is extruded from the opposite end of the die hole, the cutting blades that are installed on the outside of the die will cut it into predetermined lengths, which forms the final pellets.

Why Produce EFB Pellets?

The fundamental purpose of producing EFB pellets lies in transforming agricultural waste into highly valuable resources. This approach not only resolves the most urgent waste disposal challenge of the palm oil industry by converting it into clean energy and economic benefits, but also significantly promotes the green and sustainable development of the new energy sector.

Waste Management

Palm oil mills generate substantial amounts of empty fruit bunch waste during production. This waste is bulky and occupies large areas. If they pile up randomly, they will rot and emit foul odors, attract mosquitoes and other pests, and potentially contaminate water sources and soil.

Reducing Energy Costs

Palm oil mills are major energy consumers themselves. Using self-produced EFB pellets to replace coal or natural gas for providing steam and electricity to boilers can significantly reduce energy purchase costs.

Clean Combustion

Compared to coal, EFB pellets have extremely low sulfur content, which produces minimal sulfur oxides during combustion. Processing them into pellets and burning them cleanly in specialized equipment can significantly reduce pollution emissions.

Abundant Raw Materials

It is very common in Southeast Asia, particularly in Indonesia and Malaysia. Sufficient material can be obtained from oil palm plants, which has abundant material resources.

RICHI MACHINERY

EFB Pellet Machine Models and Parameters

Below are the specifications for RICHI EFB pellet machines. If you don’t know how to select, please contact us directly. Additionally, we can customize EFB pellet machines to meet individual customer requirements.

Applications of the EFB Pellet Machine

The final EFB pellets have multiple applications.

clean solid fuel

EFB pellets serve as clean solid fuel which replaces fossil energy sources. They are widely used in palm oil mills, biomass power plants, district heating systems, and other applications.

biochar

EFB pellets can be carbonized into biochar, which possesses a porous structure and serves as an excellent fertilizer carrier. It can adsorb nutrients and moisture, which are slowly released to plants and improve the utilization rate of fertilizers.

potassium fertilizer

The ash after burning EFB pellets can also serve as potassium fertilizer, which can effectively improve soil structure and increase soil organic content.

bedding materials

EFB pellets that have undergone special processing can serve as bedding material for livestock and poultry farms. They are highly absorbent, which keeps animal housing dry. After using, they can be composted together with manure and returned to farmland.

EFB Pellet Machine Component Display

Investing in a high-quality EFB pellet machine is essentially an investment in the outstanding performance, wear resistance, and stable working of its core components. The core components of the biomass pellet mill for sale are the key to determine whether it can efficiently and stably convert loose hollow fruit cluster fibers into high-density pellets.

- Feeder: Driven by a variable-frequency motor, it enables precise control of feed rates by adjusting rotational speed, which ensures stable production. It is responsible for uniformly and continuously feeding processed materials into the next stage.

- Ring Die and Press Rollers: Due to the long EFB fibers and their high wearing of the silica impurities, the ring die of the EFB pellet machine must be manufactured from an extremely wear-resistant, high-toughness special alloy steel and undergo a specialized heat treatment process. The surface of the press roller also requires extremely high wear resistance. Both it and the ring die are a pair of wear parts that need to be replaced simultaneously on a regular period.

- Drive System: It usually includes the main motor, gear reducer and spindle. High-quality gear transmission systems are essential, as they must withstand high loads over a long period of operation to ensure stable speed of the ring die, which ensures uniform output and pellet quality.

- Electrical Control Cabinet: It can monitor equipment operating status in real time, display key parameters such as output and temperature, and features automatic fault detection and alarm functions. This enables automated equipment operation.

Projects for EFB Pellet Machine

Up to now, RICHI Machinery has successfully completed multiple EFB pellet line all over the world.

Case Study of EFB Pellet Machine in Malaysia

Client Background: This client is a medium-sized palm oil mill located in Sabah, Malaysia. It processes large quantities of palm fruit bunches daily and generates approximately 50 tons of empty fruit bunch waste.

Customer Requirements: The most urgent need is to address the accumulation of EFB waste in a low-cost, highly efficient way that meets local environmental regulations and avoids fines for pollution violations. Additionally, the customer aims to utilize the calorific value of EFB to fuel the plant’s boilers, which can replace part of the expensive natural gas and reduce steam production costs.

Case Study of EFB Pellet Machine in Indonesia

Client Background: This client is a palm oil producer based on Sumatra Island, Indonesia. They recognized an opportunity to convert palm oil industry waste into commercial energy. The region features a high concentration of palm oil mills, with an abundant and low-cost supply of EFB raw materials.

Customer Requirement: They not only need to process waste from their own industry but also aim to produce and sell EFB pellets as a commercial product to generate profits.

Case Study of EFB Pellet Machine in Thailand

Client Background: This client is an agricultural cooperative in Thailand that comprises dozens of small and medium-sized palm growers. The cooperative operates a centralized palm oil mill, but the spent fruit bunches (EFB) generated after oil extraction are scattered across various locations. Most EFB is sold to middlemen at extremely low prices or simply piled up and buried.

Customer Requirements: The core requirement is to consolidate dispersed EFB, increase the value by processing them into EFB pellets, and ultimately return the profits from pellet sales to cooperative members to boost overall income.

Supporting Equipment for EFB Pellet Line

If you are interested in mass-producing EFB pellets, we strongly recommend establishing a complete and automated biomass pellet plant. RICHI can provide customized EFB pellet machines and all necessary supporting equipment for your production line. Below is a list of basic supporting equipment for an EFB pellet line for your reference.

EFB Hammer Mill

The original EFB fibers are long and have uneven moisture content, so they cannot be directly compressed. Therefore, a EFB hammer mill is required to cut the long fibers into uniformly short lengths. This reduces fiber entanglement and improves material flowability.

EFB Dryer

A dryer is used to reduce the moisture content of the material to the optimal range of 12%-15%. Adequate moisture acts as a lubricant and weak binder during compression, but excessive moisture generates steam, which causes the pellets to become loose and break apart.

EFB Pellet Machine

The EFB pellet machine processes crushed raw materials into solid fuel. As the core component of the entire EFB pellet line, the EFB pellet mill directly determines the production capacity of the EFB pellet line.

EFB Counter-flow Cooler

Freshly molded pellets are extremely hot and soft in texture. They must be immediately transferred to a cooler for rapid cooling. This cooling process will remove surface heat and some moisture from the pellets, so that they can be hardened and set into shape. This facilitates subsequent storage and transportation.

EFB Automatic Packing Scale

After cooling, EFB pellets can be packed into bags of the required size and stored in a dry location to prevent moisture absorption.

About rICHI

RICHI Machinery was established in 1995 and holds European CE certification, Swiss SGS certification, French BV certification, and ISO 9001 quality management system certification, with a complete international trade system. To better serve our global customers, We have also launched multiple platforms including Alibaba International, Google Ads, Made-in-China.com, and SEO optimization, and own a comprehensive cross-border e-commerce operation system. Up to now, our products have been exported to 108 countries and regions across Europe, the Americas, the Middle East, Asia, Africa, and Southeast Asia, which has earned the trust and recognition of a wide range of customers.

Information Sharing

Customized Solutions

After-Sales Service

Professional Certification

Frequently Asked Questions

What are the raw material requirements for producing EFB pellets?

+

The most important requirement is moisture content. The moisture content of raw materials that enter the EFB pellet machine should typically be controlled between 12% and 15%. Excessive moisture prevents proper pellet formation, while insufficient moisture may cause excessive wear on the die and poor adhesion.

What is the cost of investing in an EFB pellet line?

+

Costs vary widely depending on production capacity, automation levels, and suppliers. Investment ranges from hundreds of thousands to millions of dollars. It depends on whether the line is small-scale (1-2 tons per hour) or large-scale (8-10 tons per hour). A detailed assessment based on raw material availability and market conditions is required.

What are the advantages and disadvantages of EFB pellets compared to wood pellets?

+

Advantages: The raw materials required differ. EFB pellets utilize waste materials as raw materials, which are extremely low-cost and represent resource recycling.

Disadvantages: EFB pellets may have a slightly lower calorific value and because of their inherent characteristics, they may have a higher demand on combustion equipment. Compared to wood pellets, which have a widely recognized, standardized and long-established sustainability certification system, the certification system relied upon by EFB pellets lags behind in terms of recognition, sophistication, and operational convenience. This results in greater obstacles when entering international markets.