Feed Pellet Machine

RICHI MACHINERY

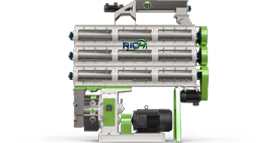

What Is A Feed Pellet Machine?

The feed pellet machine is a feed processing machine that directly presses pellets from crushed materials such as corn, soybean meal, bran, molasses, soybean meal, peanut meal, cottonseed meal, and alfalfa grass. The feed pellet machine is widely used in large, medium, and small animal feed mills and animal farms.

- Capacity: 1-40T/H

- Suitable animals: chicken, layer, goose, duck, pig, cattle, sheep, rabbit, horse, fish, shrimp, crab, pet, etc.

- Raw material: corn, grass, straw, wheat bran, rice meal, maize meal, soybean meal, sorghum, barley, cassava meal, oat, etc.

- Application: livestock farms, poultry farms, individual farmers and small and medium farms, or large, medium, and small-sized feed pellet production lines.

Technical Specifications & Model Of Feed Pellet Machine For Sale

Choosing the right feed pellet machine starts with understanding its technical specifications and model range. To meet the needs of different farm sizes and feed plant capacities, we offer multiple models with varying outputs, power configurations, ring die sizes, and applicable raw materials. Whether you need small-scale production equipment or are planning a large-scale automated pelleting line, we can help you quickly find the most suitable model. The feed pellet machine price ranges from $7,000 to $85,000, depending on the model, capacity, and configuration.

SZLH250 Small Feed Pellet Machine

- Capacity: 1-2T/H

- Main Motor Power: 22KW

- Feeder Power: 1.1KW

- Modulator Power: 1.5KW

- Ring Die Inner Diameter: 250mm

- Price: 7,000-10,000 USD

SZLH320 Feed Pellet Machine

- Capacity: 3-4T/H

- Main Motor Power: 37KW

- Feeder Power: 1.5KW

- Modulator Power: 4KW

- Ring Die Inner Diameter: 320mm

- Price: 10,000-20,000 USD

SZLH350 Feed Pellet Mill

- Capacity: 5-6T/H

- Main Motor Power: 55KW

- Feeder Power: 1.5KW

- Modulator Power: 4KW

- Ring Die Inner Diameter: 350mm

- Price: 25,000-32,000 USD

SZLH420 Feed Granulator Machine

- Capacity: 10T/H

- Main Motor Power: 110KW

- Feeder Power: 1.5KW

- Modulator Power: 7.5KW

- Ring Die Inner Diameter: 420mm

- Price: 32,000-40,000 USD

SZLH508 Feed Pellet Mill Machine

- Capacity: 15T/H

- Main Motor Power: 160KW

- Feeder Power: 1.5KW

- Modulator Power: 7.5KW

- Ring Die Inner Diameter: 508mm

- Price: 40,000-50,000 USD

SZLH558 Feed Pellet Machine

- Capacity: 20T/H

- Main Motor Power: 185KW

- Feeder Power: 1.5KW

- Modulator Power: 11KW

- Ring Die Inner Diameter: 558mm

- Price: 50,000-60,000 USD

SZLH678 Feed Pellet Making Machine

- Capacity: 30T/H

- Main Motor Power: 250KW

- Feeder Power: 1.5KW

- Modulator Power: 11KW

- Ring Die Inner Diameter: 673mm

- Price: 60,000-70,000 USD

SZLH768 Commercial Feed Pellet Machine

- Capacity: 40T/H

- Main Motor Power: 315KW

- Feeder Power: 2.2KW

- Modulator Power: 11KW

- Ring Die Inner Diameter: 762mm

- Price: 70,000-85,000 USD

RICHI MACHINERY

Applications in the Production Line

Our feed pellet machines play a central role in complete feed production lines and can work seamlessly with crushers, mixers, coolers, sifters, and packing systems. They help achieve efficient, continuous, and automated feed manufacturing for various types of animals.

- Poultry Feed Manufacturing Pplant – Suitable for manufacturing pellets for chickens, ducks, and turkeys, with adjustable formulas and pellet sizes.

- Livestock Feed Production – Ideal for cattle, pigs, and sheep feed lines, supporting different die diameters for different growth stages.

- Ruminant Feed Production line – Ensures strong, durable pellets for ruminants using high-strength ring die systems.

- Fish Feed Production Line – Capable of handling special formulas for fish and shrimp feed with multi-layer conditioners.

No matter what type of feed you are producing—poultry, livestock, ruminant, or aquatic—RICHI pellet machines can be tailored to meet your specific requirements. Explore how our machines adapt to different animal feed needs and help you achieve efficient, high-quality pellet production.

Suitable Feed Pellet Machines for Different Types of Feed

RICHI Machinery feed pellet machines are flexibly adaptable to different raw materials, animal types, and production demands. Whether for poultry, livestock, ruminants, or aquatic feed, we provide tailored solutions to ensure stable equipment operation and the production of high-quality pellets. With their flexible configuration and wide applicability, the system can meet the diverse needs of farms and large-scale commercial production.

Poultry Feed Pellet Machine

Livestock Feed Pellet Machine

Ruminant Feed Pellet Mill

Aquatic Feed Pellet Machine

Grass Feed Pellet Mill Machine

Twin Screw Extruder Machine

Wet Type Extruder Machine

Dry Type Extruder Machine

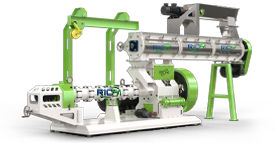

Complete Feed Pellet Production Process

In a complete feed pellet production line, the feed pellet machine works together with several upstream and downstream sections to transform raw materials into high-quality finished pellets. Each step—from crushing to final packaging—is essential for ensuring stable nutrition, uniform pellet size, and smooth machine operation. Below is a brief overview of the standard production process.

- Crushing: Raw materials such as grains, grass, or fiber materials are crushed into fine powder to ensure uniform mixing and efficient pelletizing.

- Mixing: Crushed powders are mixed with vitamins, minerals, and additives to achieve balanced nutrition.

- Pelletizing: The conditioned materials enter the feed pellet machine, where they are compressed into pellets with the required size and density.

- Cooling: Fresh pellets are hot and soft; a counterflow cooler reduces their temperature and hardness increases for safe storage.

- Screening: Fines and unqualified pellets are separated and returned for re-processing, ensuring consistent quality.

- Packaging: Finished pellets are weighed and packed using automatic packing machines for storage or sale.

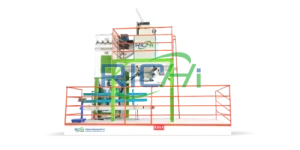

Auxiliary Equipment for Complete Feed Production Lines

In a high-efficiency and stable feed production line, auxiliary machines—such as crushers, mixers, coolers, sieving systems, and packing machines—are just as essential as the pellet mill itself. Together, they determine raw material processing efficiency, pellet quality, and the overall automation level of the production line.

hammer mill crusher

The crusher grinds materials such as corn, soybean meal, rice husk, and forage into suitable particle sizes for pelletizing. This improves the stability of mixing and pelletizing, ensuring uniform pellet density and nutrient distribution.

single-shaft twin ribbon mixer

This mixer uses a double-paddle structure for fast and uniform mixing with no dead corners. The mixing uniformity can reach over 95%, making it suitable for feed, pet food, and premix production.

Dryer for sale

The dryer reduces moisture in raw materials or pellets, keeping the final humidity within a safe range. This enhances storage stability and prevents mold and quality deterioration.

Flip Counterflow Cooler

The counterflow cooler uses reverse airflow to cool hot pellets gradually, preventing cracking and hardness loss. This results in more stable pellets with better appearance and durability.

Rotary Classifier

The rotary grading sieve classifies pellets and removes fines or unqualified pieces, ensuring consistent pellet size and stable product quality.

fully automatic packaging scale

Automatic packaging machines are responsible for weighing, filling, and sealing, enabling high-speed and precise bagging for easy subsequent transportation and storage.

Related Cases Of The Feed Pellet Machine

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines.

Video Of RICHI feed Pellet Machine

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines.

Frequently Asked Questions

When selecting the right feed pellet equipment, many customers have questions about capacity, raw material compatibility, energy consumption, die options, and complete production line configuration. To help you understand our machines and their applications more clearly, we have prepared a FAQ section. We hope these answers provide practical information and help you plan your feed production project more smoothly.

–

What raw materials can the feed pellet machine process? And can one machine produce different pellet?

A modern feed pellet machine is designed to process a wide variety of raw materials commonly used in the production of poultry, livestock, ruminant and aquatic feed.

These materials include corn, wheat, soybean meal, rice bran, cottonseed meal, alfalfa, grass, straw, peanut shells, cassava, fish meal, shrimp meal, vitamins, minerals, premixes and other powdered or fibrous ingredients. Whether your feed formula contains high protein, high fiber, or a mixture of agricultural by-products, the machine can handle it efficiently as long as the materials are properly crushed and moisture is well controlled.

Yes, one machine can produce different pellet sizes. By changing the ring die (or flat die) or adjusting the cutter, you can easily make pellets of different diameters. Larger pellets are suitable for cattle and sheep, medium pellets are ideal for poultry, and smaller pellets are used for aquatic species or young animals.This flexibility allows one unit to meet various production requirements without the need to buy multiple machines.

–

How To Make Fish Feed Pellet?

The most commonly used equipment in the production of aquatic animal pellet feed is the fish feed extruder which can produce expanded fish pellet feed.

By using different types of screws to control the density of finished fish pellets, the fish feed extruder can produce floating and sinking fish feeds according to the feeding characteristics and habits of fish. The expansion heating process can kill some pathogenic bacteria and most viruses, thus reducing the level of toxins in feed materials.

The fish feed extruder can produce aquatic feeds with different particle sizes and shapes. And these feeds can remain stable in water for a long time, so it can reduce the waste of feed nutrition. The fish feed extruder can produce aquatic animal feed that is more resistant to mechanical damage, thus reducing the amount of fine powder produced during transportation.

Recently, more and more people are using fish feed extruders. If you have the intention, please contact us.

–

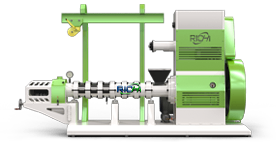

How Does A Feed Pellet Machine Work?

The rapid development of the aquaculture and feed industry has greatly promoted the development and progress of feed machinery. Equipment such as feed pellet making machines have become more and more widely used, and technological breakthroughs have also been made. After being made into feed pellets, nutrition is not lost, the surface of pellets is smoother, the hardness is more suitable for animal digestion, and it can kill harmful microorganisms in the feed, making it ideal equipment to reduce breeding costs and improve economic benefits.

The process of granulation is to remove iron from the powdered material through the permanent magnet sleeve, and then send it into the conditioner through the variable frequency feeder. The powder is mixed with the steam added. At this time, the feed moisture is reached 15%-17% and the temperature is about 80℃. After the process, the materials are sent into the pelletizing chamber. Then the powder is pressed into pellets by the ring die and the press roller, and the produced feed pellets are sent out of the machine through the feeding disc. Then, the cutter installed outside the die is used to cut pellets at an appropriate length, and the position of the cutter can be adjusted to control the length of the pellets.

RICHI Machinery can provide you with a 1-40t/h feed pellet machine for sale. We can also make customized designs according to your needs.

–

How To Choose the right Animal Feed Pellet Machine?

Choosing the right feed pellet machine involves evaluating your raw materials, target animals, required pellet specifications and production scale. For small and medium farms, a lower-capacity machine may be sufficient, but for commercial feed mills, choosing the correct production range is critical. Modern industrial pellet machines—such as the 1–40T/H models provided by RICHI—are suitable for poultry, livestock, ruminant and aquatic feed production on a professional level.

First, define your production demand. If your daily output is less than 20 tons, a 1–10T/H machine is usually enough. For large-scale feed plants, 10–40T/H models offer better efficiency and cost performance.

Second, consider the type of raw materials you use. High-fiber materials (grass, straw) require strong conditioning and suitable compression ratios, while high-protein formulas (fish meal, soybean meal) need precise temperature and moisture control.

Ensure the machine can produce multiple pellet sizes by easily changing the ring die. Also evaluate automation level, electricity consumption, maintenance cost, and the availability of spare parts. Finally, choose a supplier with strong technical support. A reputable manufacturer like RICHI can provide engineering solutions, installation guidance and after-sales services, ensuring long-lasting performance and a high return on investment.

–

We have a dairy farm and want to produce cattle feed pellets, what capacity is suitable?

For cattle feed processing plant, the capacity of the feed pellet machine should match the daily feed consumption of the cows, which is approximately 6 kg per cow per day. For example, if there are 2000 cows, the daily feed requirement is 2000 * 6 kg = 12 tons. If the machine operates for 6 hours per day, we recommend our SLZH250, which has a capacity of 1-2 tons per hour and can fully meet your needs.

–

I plan to start a commercial feed plant, what is included in a complete line?

A commercial feed pellet line for poultry, livestock, or fish generally includes:

- Crusher – for crushing grains and fibrous materials.

- Mixer – for uniform feed formula.

- Feed pellet machine – ring die or flat die, capacity 1–40T/H depending on scale.

- Conditioner – to adjust moisture and temperature.

- Cooler – for reducing pellet temperature and increasing durability.

- Sifter – to separate fines and ensure uniform pellets.

- Packing machine – for automated bagging.

- Optional auxiliary equipment – conveyors, storage bins, dust collection.

Selecting a reputable manufacturer like RICHI ensures integration of all equipment and technical support for smooth production and consistent feed quality.