Feed Pellet Mill For Sale

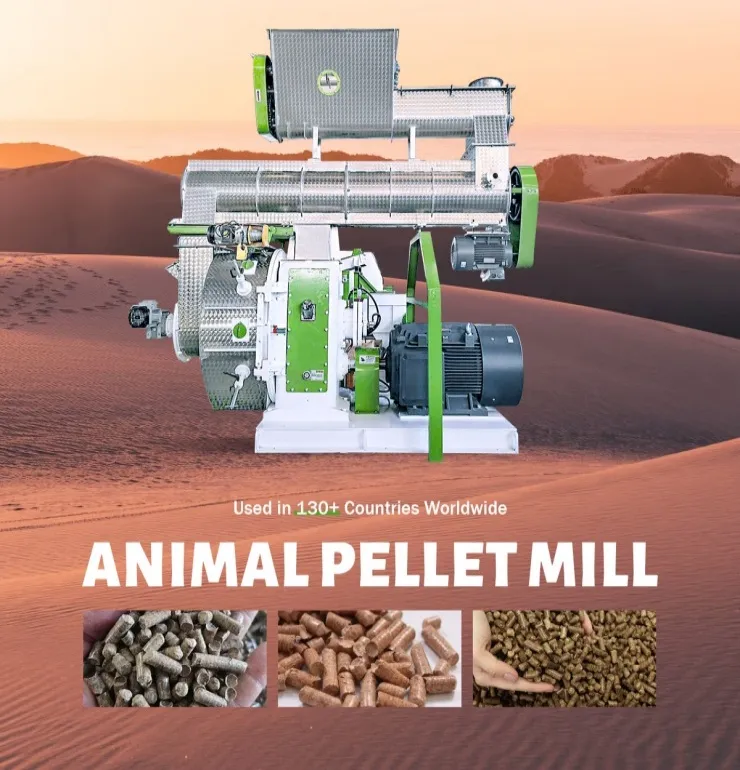

RICHI Feed Pellet Mill for sale is a specialized machine for processing powdered feed into pellets.

General Production for Feed Pellet Mill

RICHI Machinery not only provides stable and reliable animal feed mill equipment but also customizes feed production solutions based on your raw material and production requirements, which ensures your purchase and operation are carefree.

Feed Pellet Mill For Sale

This equipment employs advanced mechanical compression technology, which transforms powdered raw materials such as corn, soybean meal, and wheat bran into uniformly sized pellet feed through tempering, compression, and shaping processes. Widely used in various scenarios including pig, chicken, duck, cattle, rabbit, and aquaculture farming, it serves as a key piece of equipment for modern farms to improve efficiency.

As the modern livestock industry continues to develop, whether you operate a small farm or a larger operation, you may encounter some challenging issues. These problems can directly impact your farm’s production efficiency and animal health, which ultimately affects your economic returns. This feed pellet mill for sale specifically aims to address the problem of traditional powdered feed. Animals tend to be picky eaters, which results in nutritional imbalances. Pelleted feed ensures each animal receives a complete nutritional intake. Powdered feed generates a lot of dust during feeding, with a waste rate of 15%-20%. Pellet feed reduces waste to below 5% and lowers the risk of respiratory diseases. Additionally, pellet feed has a higher density, which extends its shelf life by 2-3 times compared to powdered feed. It also reduces transportation volume by 40%, which greatly lowers storage and logistics costs.

RICHI MACHINERY

Product Categories

Different animals have different physiological structures, feeding habits, and feed formulations. Feed pellet mill for sale needs to optimize core parameters such as mold specifications, pellet hardness, and conditioning levels to create specialized models tailored to specific animals.

Feed Pellet Mill for sale working Video

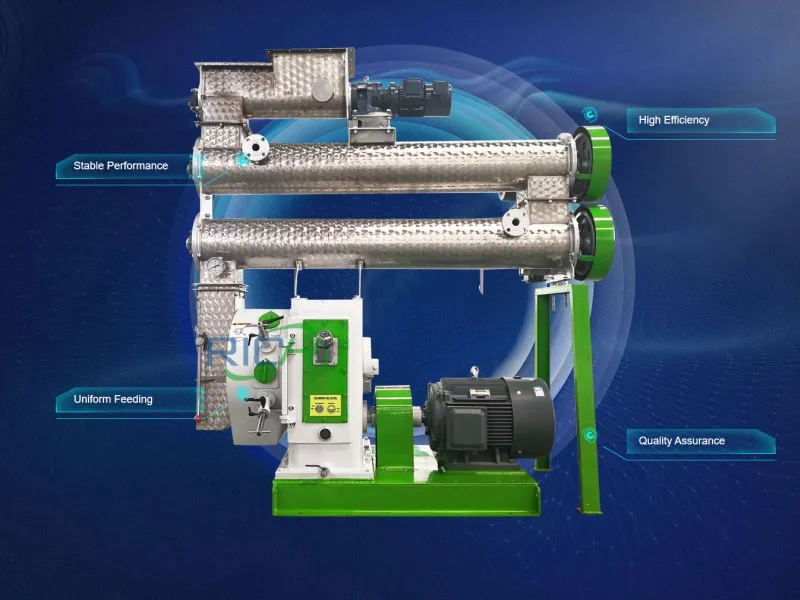

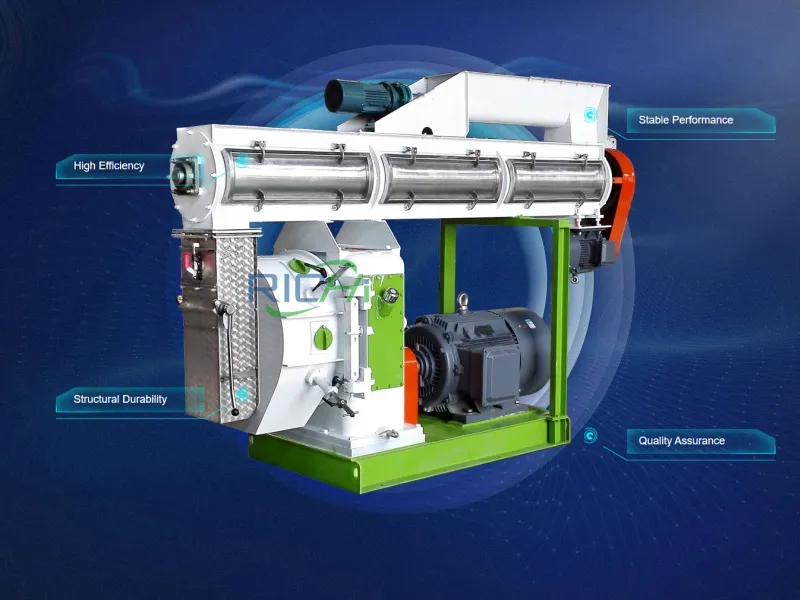

The production process of feed pellet mill for sale can be divided into four key steps: feeding, conditioning, pelleting, and cutting, which transforms powdered feed ingredients into high-density pellet feed. Through mechanical compression and heat treatment, this process not only reduces transportation and storage losses but also improves animal feed intake efficiency and digestibility.

Feeding

Based on the formulation requirements of different animal feeds, the feed pellet mill for sale employs intelligent control to automatically adjust the feeding rate. This ensures that various feed powders are mixed proportionally without disrupting production or causing blockages due to overfeeding.

Conditioning

The mixed powdered feed enters the tempering machine through the conveyor belt, where it is thoroughly mixed with steam. The steam adjusts the moisture content of the raw materials to 15%-18% and raises the temperature to 60-80°C. This not only improves subsequent pellet formation but also breaks down anti-nutritional factors.

Pelleting

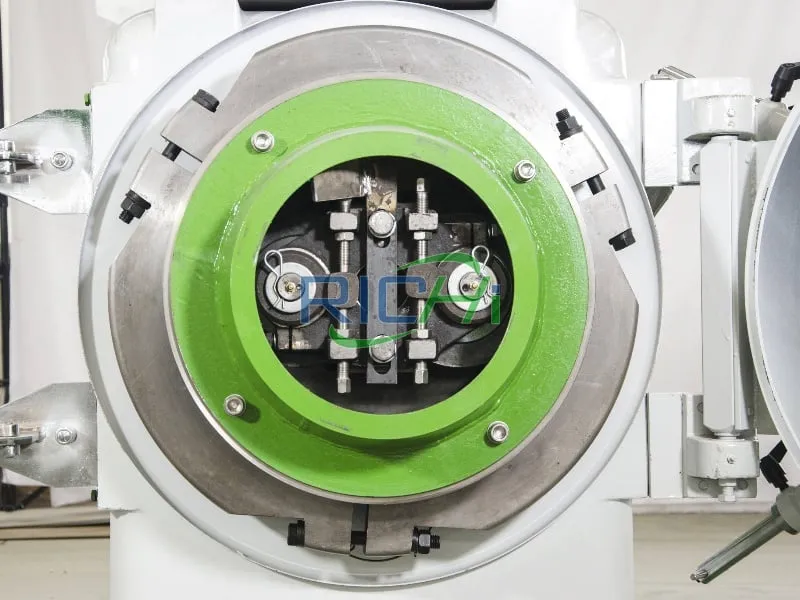

The tempered raw material is conveyed into the pelleting chamber, where the press rollers and ring die operate at high speed. The ring die remains stationary while the press rollers rotate around the main shaft, and the material is forcibly squeezed through the uniform small holes in the ring die.

Cutting

After the feed pellets are extruded from the ring die, the rotating cutting blades positioned immediately outside the die will cut them to the preset length (e.g., 2–12 mm, suitable for different animals such as chickens, pigs, rabbits and etc.), so that they form uniformly sized feed pellets.

Post-Processing

Freshly produced pellets are hot and contain high moisture. Some models will be equipped with a cooling system to reduce pellet temperature to room temperature and moisture content below 12%, which will prevent mold growth during storage. A screening device can also be added to remove broken particles.

RICHI MACHINERY

Product Display

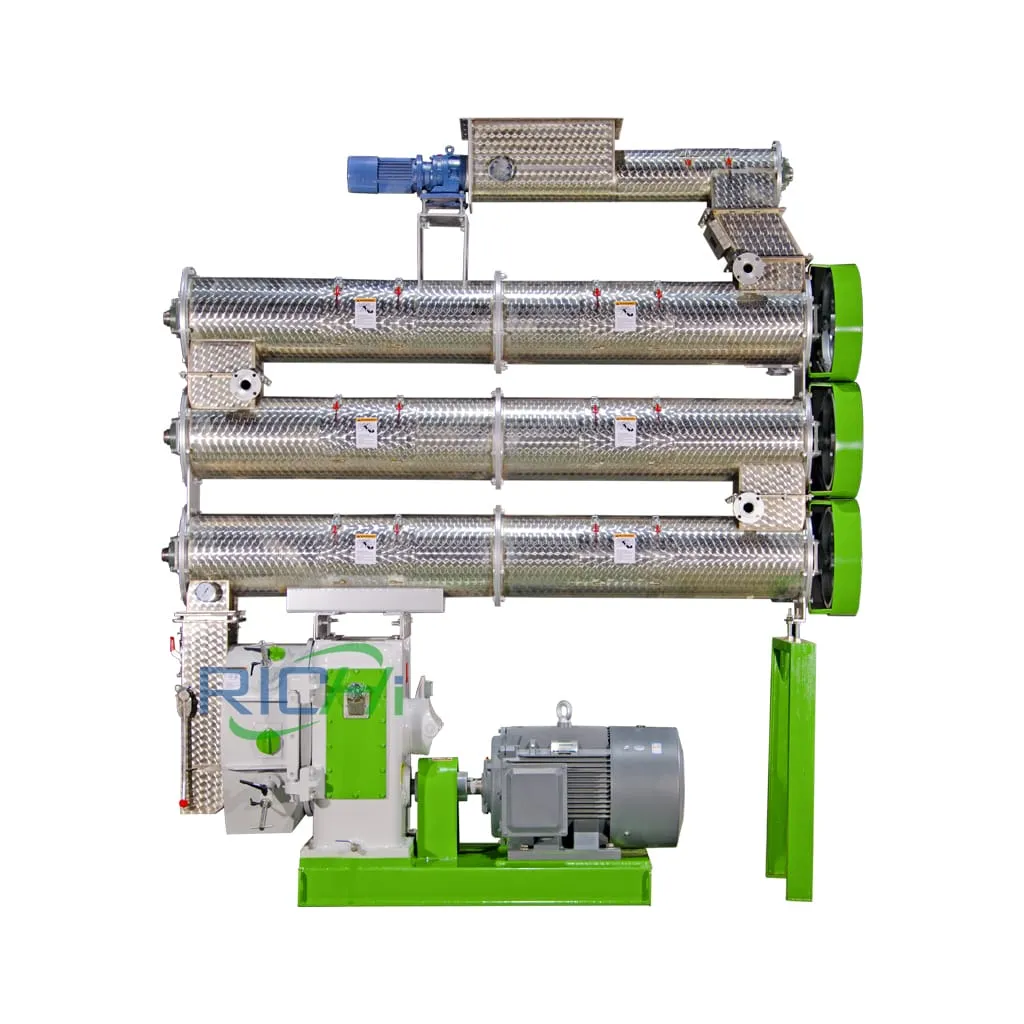

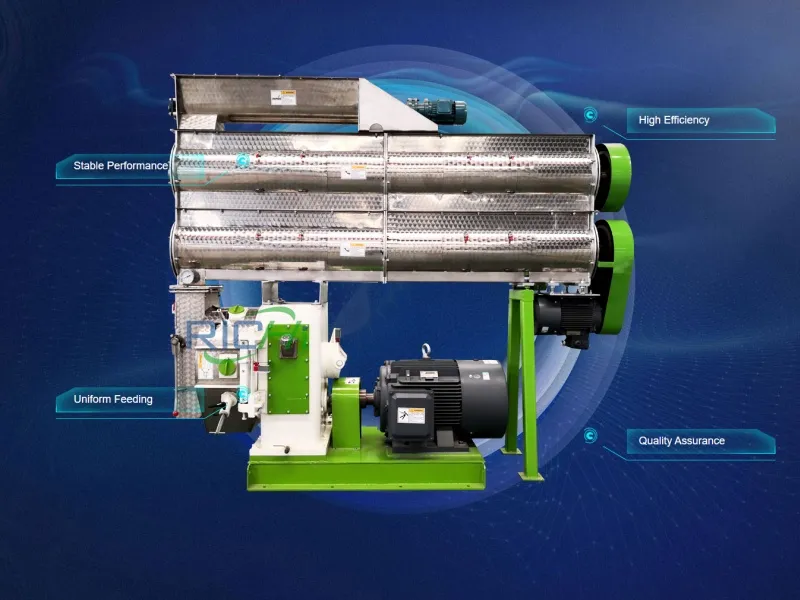

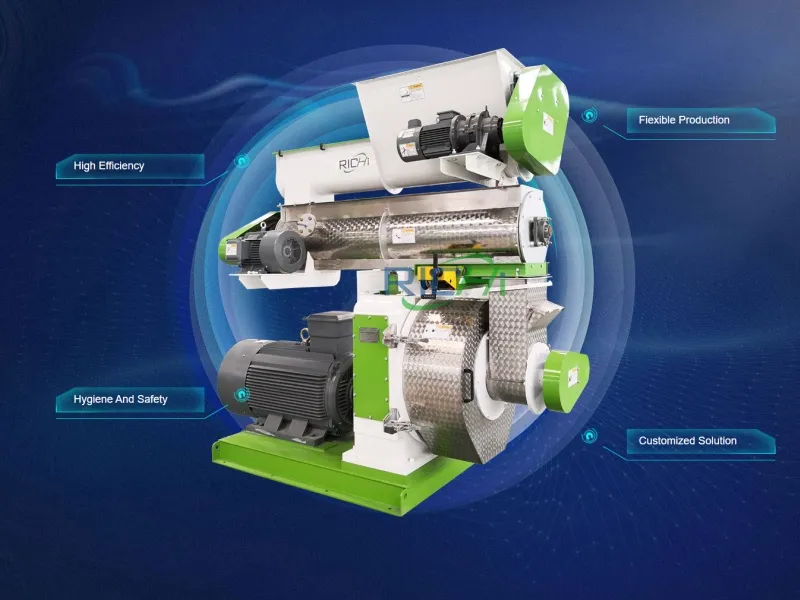

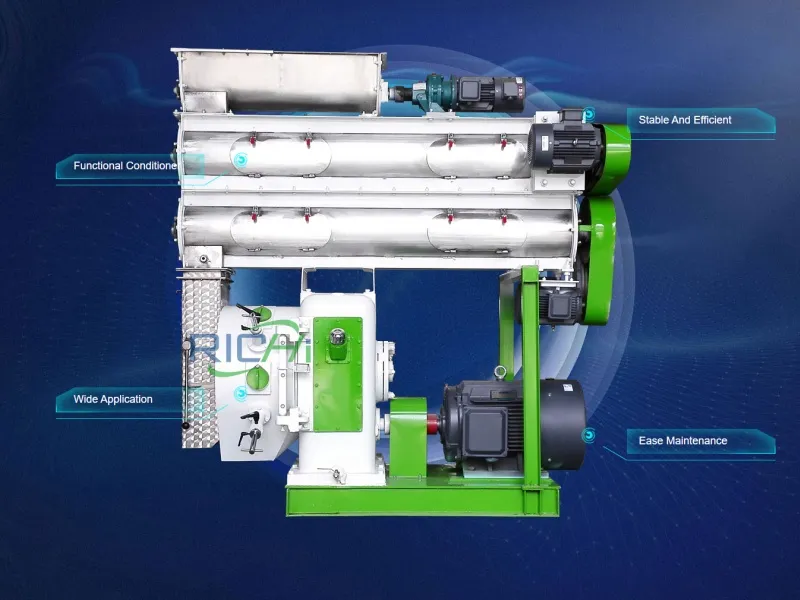

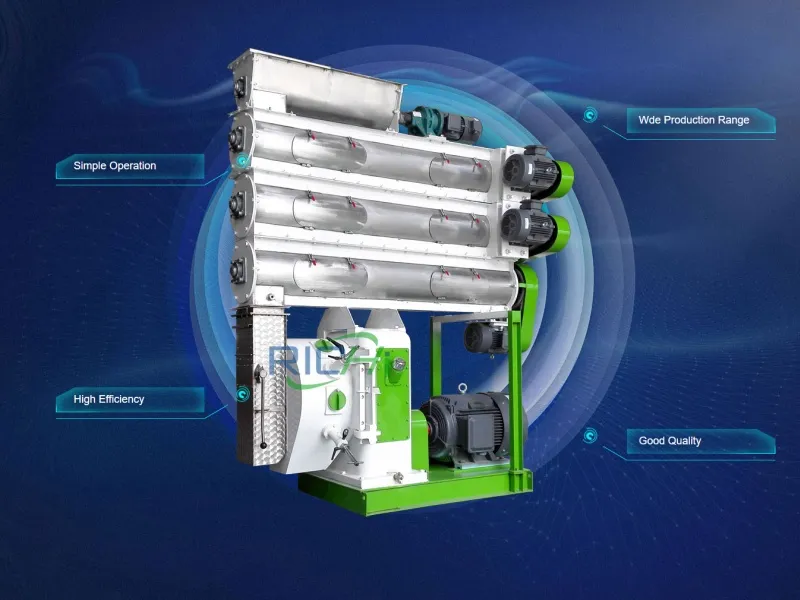

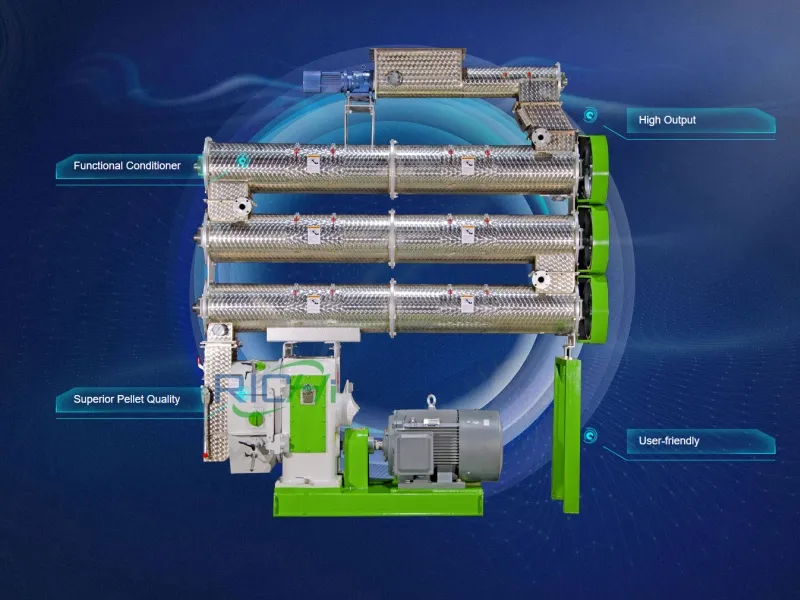

In the operation of feed pellet mill for sale, the drive system, feeding system, ring die, conditioner, Siemens motor, and cutting device are the key components that ensure pelletizing efficiency and pellet quality.

Models and Prices of Feed Pellet Mill For Sale

The feed pellet mill for sale features high output and low energy consumption, primarily designed for processing various animal feed pellets in medium or large-scale feed mills. Below are the specifications for the ring die feed pellet mill machine. If you’re unsure about selection, please contact us directly.

SZLH250 Feed Pellet Mill For Sale

- Capacity: 1-2T/H

- Main motor power: 22kw

- Feeder power: 1.1kW

- Conditioner power: 1.5kw

- Ring die diameter: 250mm

- Final pellet diameter: 2-12mm

- Price range: 7,000 -10,000$

SZLH320 Feed Pellet Mill For Sale

- Capacity: 3-4T/H

- Main motor power: 37kw

- Feeder power: 1.5kW

- Conditioner power: 2.2kw

- Ring die diameter: 320mm

- Final pellet diameter: 2-12mm

- Price range: 15,000 -20,000$

SZLH350 Feed Pellet Mill For Sale

- Capacity: 5-7T/H

- Main motor power: 55kw

- Feeder power: 1.5kW

- Conditioner power: 3kw

- Ring die diameter: 350mm

- Final pellet diameter: 2-12mm

- Price range: 20,000 -30,000$

SZLH420 Feed Pellet Mill For Sale

- Capacity: 8-12T/H

- Main motor power: 110kw

- Feeder power: 1.5kW

- Conditioner power: 7.5kw

- Ring die diameter: 420mm

- Final pellet diameter: 2-12mm

- Price range: 30,000 -40,000$

SZLH508 Feed Pellet Mill For Sale

- Capacity: 10-18T/H

- Main motor power: 160kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Ring die diameter: 508mm

- Final pellet diameter: 2-12mm

- Price range: 40,000 -60,000$

SZLH558 Feed Pellet Mill For Sale

- Capacity: 15-25T/H

- Main motor power: 180kw /220kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Ring die diameter: 558mm

- Final pellet diameter: 2-12mm

- Price range: 60,000 -70,000$

SZLH678 Feed Pellet Mill For Sale

- Capacity: 20-30T/H

- Main motor power: 220kw /250kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Ring die diameter: 678mm

- Final pellet diameter: 2-12mm

- Price range: 70,000 -80,000$

SZLH768 Feed Pellet Mill For Sale

- Capacity: 25-40 T/H

- Main motor power: 250kw /280kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Ring die diameter: 768mm

- Final pellet diameter: 2-12mm

- Price range: 80,000 -90,000$

SZLH858 Feed Pellet Mill For Sale

- Capacity: 28-45 T/H

- Main motor power: 315kw /355kw

- Feeder power: 2.2kW

- Conditioner power: 15kw

- Ring die diameter: 858mm

- Final pellet diameter: 2-12mm

- Price range: 90,000 -100,000$

Benefits of Animal Feed Pellets

Animal pellet feed transforms powdered raw materials into uniform pellets through the pelleting process. Its advantages are not only reflected in the optimization of the feed itself but also create value for farms across multiple aspects, including farm management, animal growth, and cost control.

Improving Feed Utilization

Compared to traditional powdered feed, pellet feed uniformly covers nutrients such as protein, crude fiber, and vitamins. Animals cannot selectively eat preferred concentrate feed while discarding coarse fiber as they would with powdered feed, which ensures the balanced intake.

Reducing Transportation and Storage Losses

The pellets are compact in structure and moderately hard, so there is no risk of nutrient imbalance due to raw material separation during storage. Meanwhile, the small surface area exposed to air reduces the probability of moisture absorption.

Adapting to Animal Feeding and Digestive Habits

The hardness and size of pellet feed can be adjusted according to different animal species to adapt to their feeding habits, which can effectively enhance the nutritional conversion efficiency of the feed.

Advantages of Feed Pellet Mill For Sale

The animal feed pellet mill shows significant advantages in feed processing, animal husbandry, and productivity by compressing powdered feed into pellets.

High Output And Low Energy Consumption

Catering to Diverse Needs

Feed pellet mill machine is designed to accommodate different animal species and growth stages. By replacing the ring die, the pellet mill for feed can produce pellets of various specifications to meet the feeding requirements of poultry, ruminants, aquatic animals, and other categories of livestock.

Reduce farming costs

Pelleted feed is convenient for mechanized feeding, which can reduce the time and labor intensity of manual feeding. Pelleted feed occupies less storage space, and the pellets are less prone to moisture absorption and clumping, so it can reduce losses caused by mold during storage.

Shorten the farming cycle

As a result of improved nutrient absorption efficiency and more regular feeding patterns, animal growth rates have accelerated significantly, with body weights increasing at a steady pace, which improves the commercial value of the farmed products.

Reduce pathogen pollution and dust risk

The high temperatures during the pelleting process can eliminate over 80% of bacteria in the raw materials. Additionally, pellet feed produces almost no dust, so it can avoid respiratory diseases in animals caused by dust inhalation and also reduce the impact of dust on the health of farm workers.

Case Studies of Feed Pellet Mill For Sale

RICHI Machinery has provided animal feed pellet production services to thousands of clients. Below are some turnkey projects we have undertaken. If you are interested in these projects, please contact us for more details.

1-2T/H Ruminant Animal Feed Pellet Mill

- Country: Turkey

- Primary Raw Materials: Coarse feeds such as hay and straw and concentrate feeds including corn and soybean meal.

- Background: Turkey, a major livestock nation spanning Europe and Asia, plays a major role in the upgrading of the ruminant feed industry. This enterprise is a ruminant feed producer, who has decided to upgrade its pelleting equipment to meet market demand.

1-2T/H Ruminant Animal Feed Pellet Mill

- Country: Poland

- Primary Raw Materials: Wheat, corn, rye, barley, soybean meal, rapeseed meal, etc.

- Background: A portion of feed production is used for its own poultry and pig farms. To enhance market competitiveness, this enterprise has repeatedly cooperated with RICHI to upgrade feed production equipment.

5-6T/H Shrimp Feed Pellet Mill For Sale

- Country: Netherlands

- Primary Raw Materials: Fish meal, soybean meal, wheat flour, shrimp head meal, vitamins, minerals, etc.

- Background: To address the growing demand in the aquaculture market, the decision was made to construct a new aquatic feed factory. The Dutch entrepreneur based on extensive experience in feed processing equipment selected RICHI as the partner for this project.

Additional Equipment for Animal Feed Production Lines

The animal feed production line is a complete process system from the raw material pretreatment to the final pellet. In addition to the core feed pellet mill for sale, there are several other types of equipment that must work together here. Below is a detailed introduction to other key equipment in the production line, arranged in the order of the production process.

Powder Cleaning Screen

The powder cleaning screen is mainly used for the initial cleaning of powdered raw materials in feed mills. It effectively breaks up clumps within the powdered materials and separates large contaminants. This protects machinery and equipment from malfunction or damage.

Feed Crusher

Feed crusher is used to crush raw materials, which can crush all kinds of granular materials such as corn, sorghum, wheat, beans, broken cake meal, and other materials.

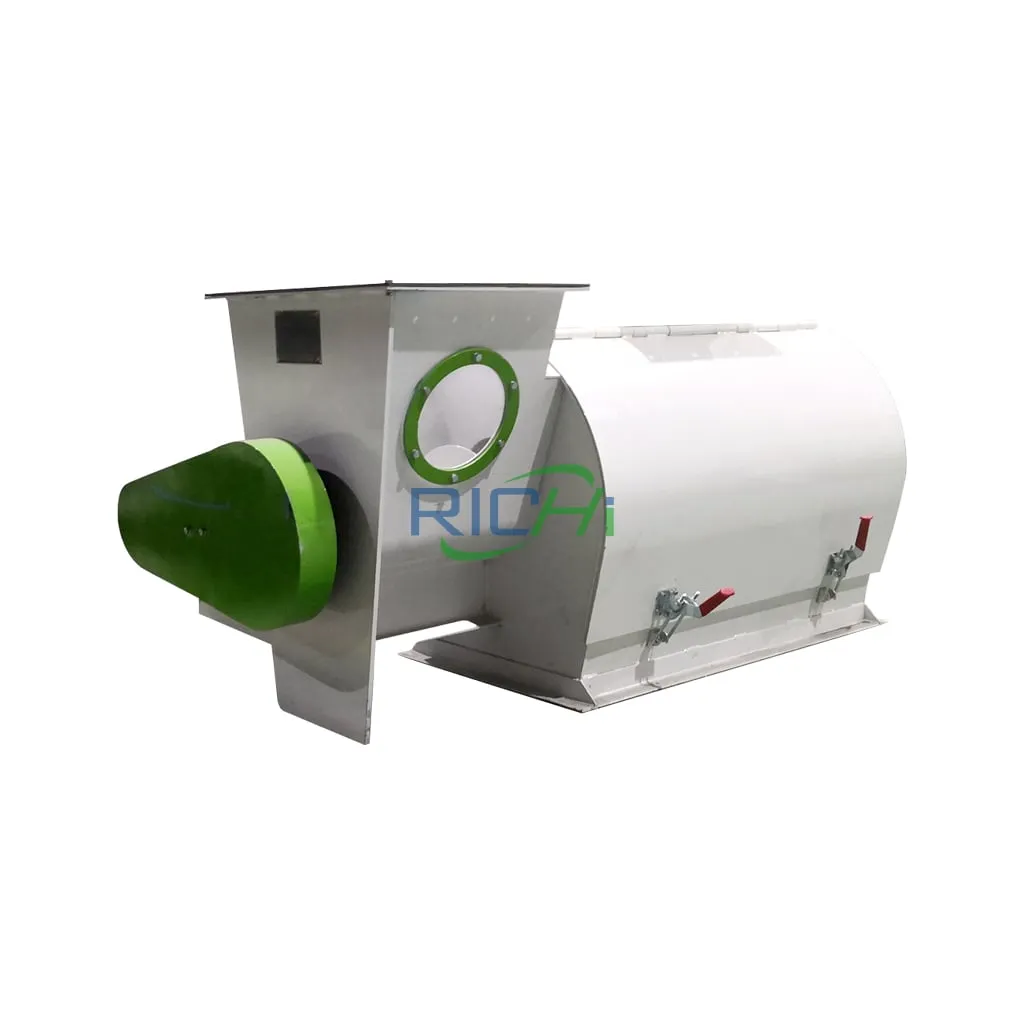

Feed Mixer

Feed mixers are widely used in small and medium-sized feed mills to blend powdered materials, so that the mixture is evenly distributed, which ensures the quality of compound feed.

Counter Flow Cooler

The cooler employs counter flow cooling principles to ensure sufficient and uniform cooling of the particles. The temperature of the cooled pellets does not exceed room temperature by more than 3–5℃.

Rotary Grade Separator

The rotary grade separator is a highly efficient material grading and screening device widely applied in many industries including grain, feed, flour, chemical, and food processing.

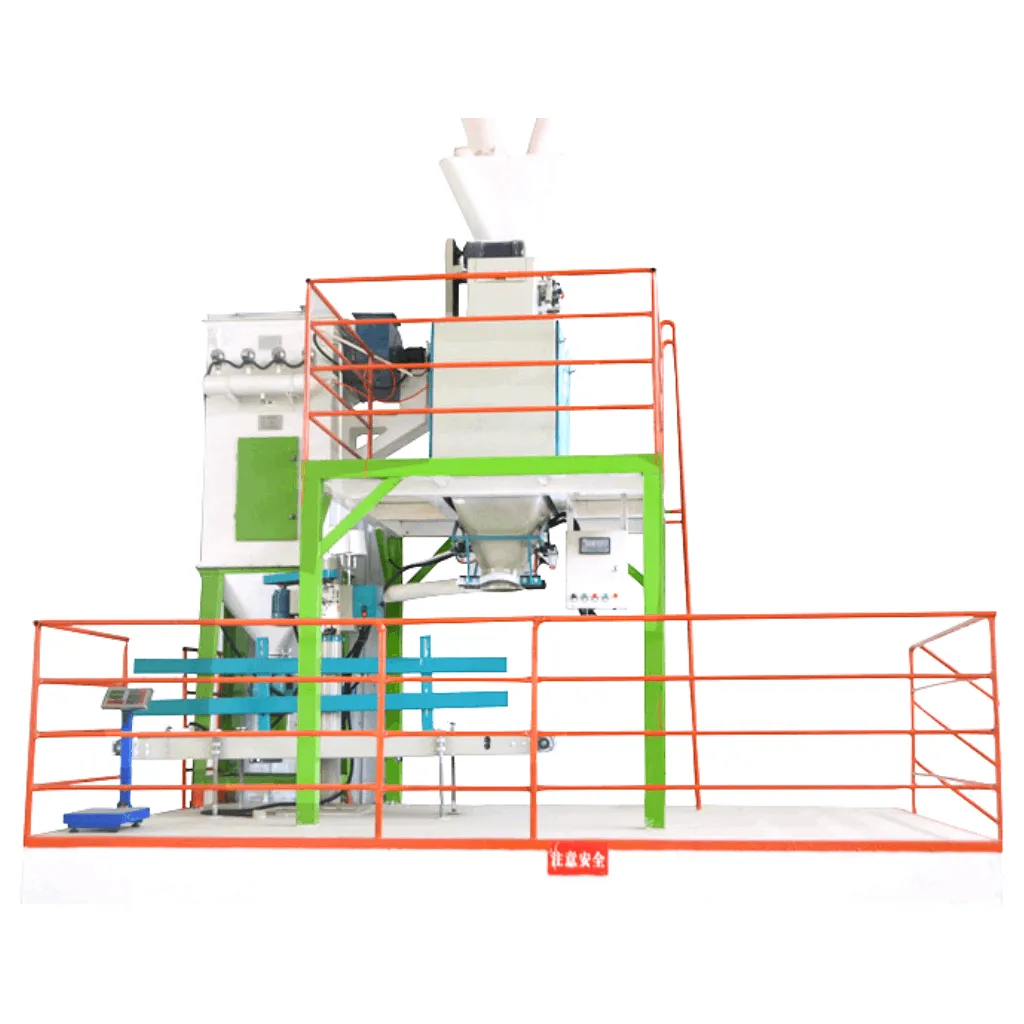

Automatic Packing System

The automatic packing system is suitable for the quantitative weighing and packaging of pellets and powdered materials, which is a professional quantitative weighing and packaging equipment. It features fast packaging speed, high efficiency, and stable operation.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.

FAQ About Feed Pellet Mill For Sale

Does the feed pellet mill for sale only produce pellet feed? Can it be adapted to meet the needs of different animals?

+

They are not limited to producing a single pellet type. By replacing ring dies and adjusting parameters, the pellet feed mill machine can accommodate most farmed animals.

- Poultry and Livestock: We can change the die hole diameter (chicks: 2-3mm, pigs: 8-12mm, ruminants: 4-10mm) and adjust roller pressure to control pellet hardness.

- Aquaculture: We should match specialized ring die (aperture 1-4mm) to produce sinking shrimp pellets and floating fish feed.

Could you provide some animal feed formulations?

+

Sure, but there are different feed formulations for different animals. Below are some common animal feed recipes.

1. Poultry Feed Formulations ( Examples for chickens and ducks)

- Laying Hens: Corn 62%, Soybean Meal 22%, Limestone Powder 8%, Bran 4%, Premix (Vitamins + Minerals + Enzymes) 3%, Salt 0.3%, Methionine 0.2%, Vegetable Oil 0.5%

- Meat Ducks: Corn 65%, Soybean Meal 18%, Cottonseed Meal 5%, Bran 6%, Premix 3%, Salt 0.3%, Lysine 0.2%, Calcium Carbonate 0.5%

2. Livestock Feed Formulations ( Examples for Pigs and Rabbits)

- Pigs: Corn 65%, Soybean Meal 18%, Bran 8%, Rice Bran 5%, Premix 3%, Limestone Powder 0.8%, Salt 0.3%, Baking Soda 0.2%

- Rabbits: Alfalfa Meal 25%, Corn 35%, Soybean Meal 15%, Bran 12%, Cottonseed Meal 5%, Premix 3%, Salt 0.5%, Shell Flour 1.5%

3. Ruminant Feed Formulations ( Examples for Cattle and Sheep)

- Dairy Cattle: Silage Corn 40%, Alfalfa Hay 15%, Timothy Grass 10%, Corn 20%, Soybean Meal 8%, Cottonseed Meal 3%, Premix 3%, Salt 0.5%, Baking Soda 0.5%

- Meat Sheep: Corn Stalk Meal 35%, Silage Corn 25%, Corn 20%, Soybean Meal 12%, Bran 5%, Premix 2%, Salt 0.5%, Baking Soda 0.5%

4. Aquatic Feed Formulation (Examples for Fish and Shrimp)

- Grass Carp: Soybean Meal 25%, Rapeseed Meal 15%, Cottonseed Meal 10%, Fish Meal 5%, Corn 20%, Bran 12%, Rice Bran 8%, Premix 3%, Vegetable Oil 1.5%, Bentonite 0.5%

- Shrimp: Fish meal 18%, Shrimp head meal 10%, Soybean meal 25%, Peanut meal 12%, Wheat flour 20%, Bran 8%, Premix 5%, Fish oil 2%, Hydroxypropyl methylcellulose (HPMC) 0.5%