Fish Feed Pellet Making Machine

Fish feed pellet making machines are the core equipment in aquatic feed processing, whose primary function is to compress uniformly mixed powdered raw materials into granular feed under high temperature and pressure.

Introduction Of Fish Feed Pellet Making Machine

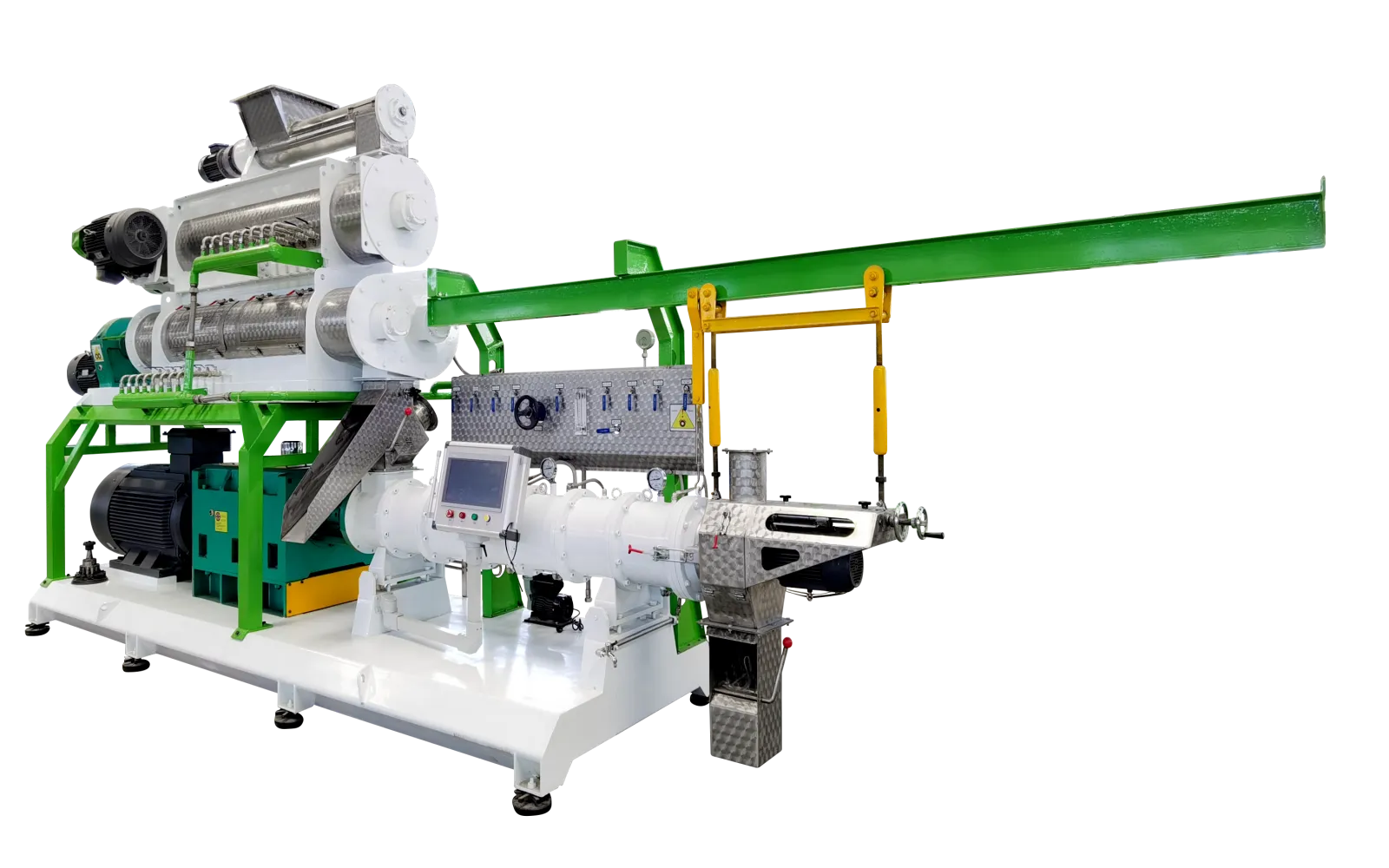

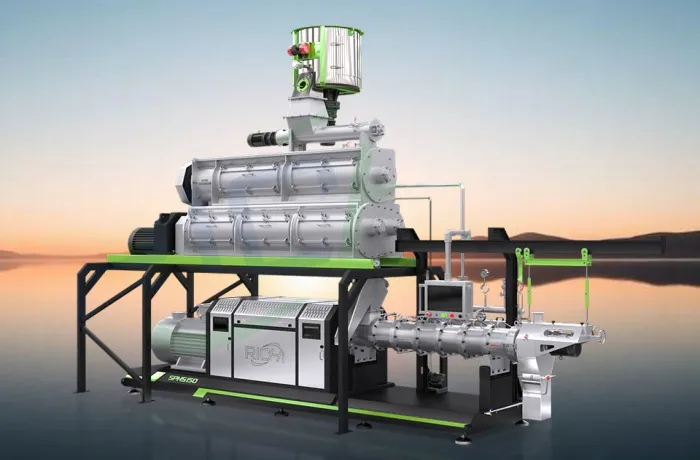

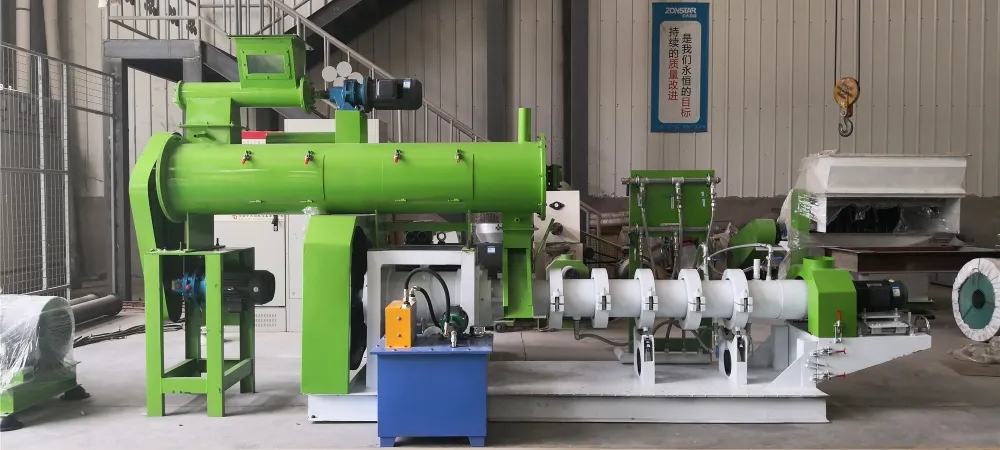

RICHI fish feed pellet making machine is a feed processing machine specifically designed for fish farming.

Fish Feed Pellet Making Machine For Sale

The RICHI fish feed pellet making machine produces pellets with a compact structure and excellent stability in water. These pellets maintain their structure for a long time without disintegrating, which are easy for fish to eat. This greatly improves feed utilization and reduces farming costs, which is more friendly to environment. Fish feed pellet making machines are indispensable equipment in modern aquaculture. Through physical transformation of feed form, they reduce waste and promote the healthy growth of fish, which provides strong technical support for the industry’s large-scale and efficient development.

The high temperature generated during the pelleting process effectively eliminate harmful pathogens in raw materials, which improves feed safety. It also prevents selective feeding in fish, and ensures they receive a comprehensive and balanced intake of nutrients. Its significance lies in addressing the disadvantages of powdered feed. When put into water, powdered feed dissolves rapidly, which not only causes the loss and waste of nutrients but also pollutes the water quality.

Categories Of Fish Feed Pellet Making Machine

There are two core pieces of equipment in fish feed processing: the sinking fish feed pellet making machine and the floating fish feed pellet making machine. Sinking fish feed pellet machines primarily produce pellet fish feed and sinking fish feed. They are mainly suitable for fish that live in the middle and lower water layers, such as carp, crucian carp, grass carp and etc. These machines offer low investment and production costs. Floating fish feed pellet machines are primarily used to produce floating fish feed, though they can also produce pellet feed and sinking feed. They are mainly suitable for surface-feeding fish species such as bass, trout, catfish, and ornamental fish. These machines usually have a high maintenance cost.

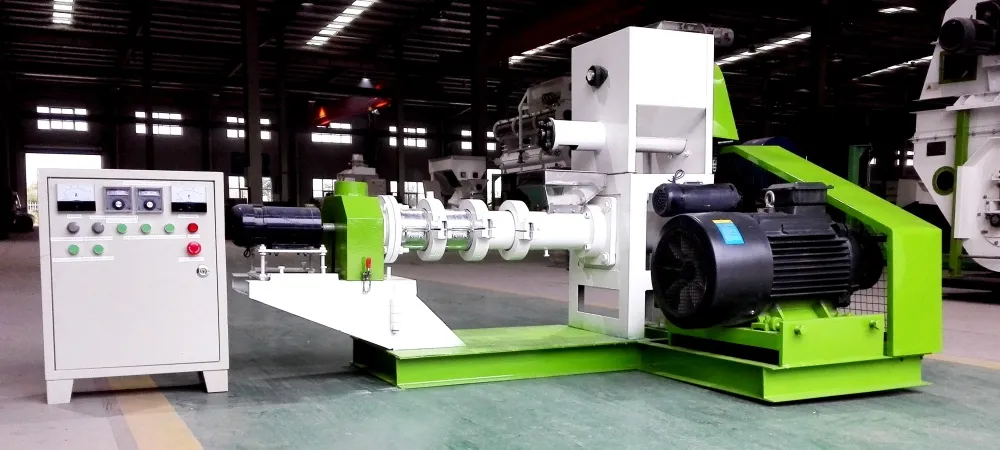

Sinking Fish Feed Pellet Making Machine

Sinking fish feed pellet machines are used to compress prepared powdered feed into sinking pellets through mechanical extrusion and high temperature. It has good stability in water and can remain intact for several hours. It is suitable for traditional aquaculture and offers a high cost-performance ratio, which is an economical and practical choice.

Floating Fish Feed Pellet Making Machine

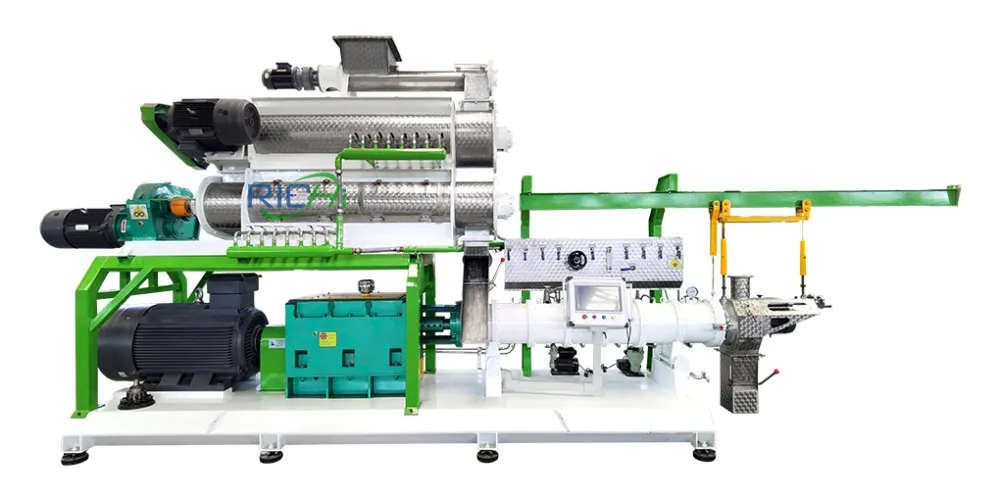

Floating fish feed pellet machines are categorized into single-screw fish feed pellet making machine and twin-screw fish feed pellet making machine. Through high temperature and high pressure, they transform conditioned powdered raw materials into structurally complex and nutritionally balanced floating pellets. With high stability in water, it maintains its integrity for tens to dozens of hours with minimal dissolution loss. Suitable for high density aquaculture, it requires significant investment but delivers higher feed conversion rates and superior farming outcomes.

Test Run Video

Below is the test run video for the floating fish feed pellet making machine and sinking fish feed pellet making machine.

Working Principle of Floating Fish Feed Pellet Making Machine

Due to the popularity of floating fish feed pellet making machine, we will primarily introduce it here. If you’d like to learn more about the sinking fish feed pellet making machine specifically, please contact us for a detailed introduction.

Brief Introduction

The floating fish feed pellet making machine generates a high-temperature and high-pressure environment through the friction of mechanical energy and steam. When the material passes through the extrusion die holes, the sudden drop in pressure causes the material to rapidly expand, which forms a porous structure. In the fish feed production line, there are also processes such as crushing, mixing, and subsequent drying, cooling, and packaging.

Conditioning

The mixed powdered raw materials first enter the conditioner, where high-pressure steam is injected into the material. This allows the material to absorb moisture and heat evenly, and the starch begins to gelatinize while the proteins start to denature, which improves the material’s plasticity. Moreover, high temperatures effectively eliminate most harmful bacteria, which provides sufficient preparation for the subsequent extrusion process.

Extrusion

The conditioned material is delivered into the extrusion chamber, which consists of one or two screws and an outer barrel. The material is conveyed forward by the screw gear, where it undergoes further mixing and compression. The friction between the material and the screw generates a large amount of heat, and there is also auxiliary heating by steam or electric heating. Under these high-temperature and high-pressure conditions, the starch undergoes complete gelatinization and the proteins fully denature.

Forming

Fully matured material is forcibly pushed by the screw to the die at the end of the extrusion chamber, which features specific shaped die holes. When the material is extruded through the die under extremely high pressure, it rapidly expands and solidifies and then forms a porous and loose structure. This is the fundamental reason why expanded feed can float on the water surface.

RICHI MACHINERY

Core Components Display

The core component of the floating fish feed extruder machine is the foundation for achieving the high temperature and high pressure expansion of the material. If you’d like to learn more about the core components of the sinking fish feed pellet making machine, please contact us for a detailed introduction.

Advantages of Fish Feed Pellet Making Machine

Fish feed offers many advantages over traditional feeding methods. These benefits are not only reflected in aquaculture outcomes but also are critical to economic efficiency and environmental protection.

Nutritious and balanced

Based on the species, growth stage, and farming model of different fish, all essential nutrients such as protein, fat, carbohydrates, vitamins, and minerals have been scientifically proportioned. This prevents nutritional deficiencies that may exist in traditional feed, and ensures healthy and rapid growth of the fish population.

High safety

High temperature and high pressure environments effectively eliminate harmful substances such as pathogenic bacteria and parasites in raw materials, which greatly enhances the safety of fish feed and reduces the risk of disease transmission.

Wide Range of Applications

RICHI fish feed pellet making machine can produce both floating and sinking feed. By adjusting formulations and process parameters, it flexibly produces feed with varying buoyancy characteristics to meet the feeding requirements of diverse aquatic species including fish, shrimp, and crabs, which has a broader application scope.

Reduction of water pollution

Modern fish feed especially extruded feed exhibits excellent stability in water, which can maintain its shape for a long time. This has greatly reduced pollution of the water body caused by uneaten feed and fish feces, which maintains a good aquaculture water environment.

Models and Specifications of Fish Feed Pellet Making Machine

This section mainly introduces the models and specifications of fish feed pellet machine. We can also customize fish feed pellet making machines according to your requirements.

1.Twin-Screw Floating Fish Feed Pellet Making Machine

| Model | RCPH120*2 | RCPH120*2 | RCPH150*2 | RCPH150*2 | RCPH185*2 | RCPH185*2 |

| Capacity(t/h) | 1-2 | 3-4 | 4-5 | 6-7 | 8-10 | 10-12 |

| Main MotorPower(kw) | 75 | 90 | 160 | 300 | 315 | 355 |

| Screw Diameter(mm) | 120 | 120 | 150 | 150 | 185 | 185 |

| DDC model and power | DDC400/300/244 with 11kw | DDC400/300/244 with 11kw | DDC500/400/244 with 11kw | DDC500/400/244 with 11kw | DDC500/300/300 with 15kw | DDC500/300/300 with 15kw |

| Price(USD) | 50,000-70,000 | 60,000-90,000 | 100,000-140,000 | 120,000-150,000 | 160,000-200,000 | 170,000-210,000 |

2.Single-Screw Floating Fish Feed Pellet Making Machine

In the table below, the DGP series is dry-process fish feed pellet making machine, while the DSP series is wet-process fish feed pellet making machine.

| Model | DGP-90B | DGP-120B | DGP-160B | DSP90-B | DSP120-B | DSP160-B |

| Capacity(t/h) | 0.2-0.4 | 0.5-0.6 | 0.8-1.0 | 0.5-0.6 | 0.7-0.8 | 1.8-2.0 |

| Main MotorPower(kw) | 37 | 55 | 90 | 37 | 55 | 90 |

| Screw Diameter(mm) | 90 | 120 | 160 | 90 | 120 | 160 |

| Conditioner power(kw) | 0.6 | 1.1 | 1.5 | 2.2 | 3.0 | 5.5 |

| Cutter power(kw) | 0.8 | 2.2 | 3.0 | 1.1 | 1.5 | 3.0 |

3.Sinking Fish Feed Pellet Making Machine

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Capacity(t/h) | 0.2-0.4 | 0.3-1 | 0.5-2 | 1.2-4 | 2-5 | 3-8 | 4-10 | 4.5-12 |

| Main motor power(kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 15 | 1.5 | 1.5 | 2.2 |

| Conditioner power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring die diameter(mm) | 250 | 320 | 350 | 420 | 508 | 558 | 678 | 768 |

| Finished pellet diameter(mm) | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 |

Case Study: Fish Feed Pellet Making Machine

RICHI fish feed pellet making machine technology is designed to fundamentally address issues such as uneven fish growth and poor stability of feed in water.

5-6 T/H Fish Feed Pellet Making Machine

- Country: Vietnam

- Fish Species: Basa Fish

- Customer Requirements: The requirements for pellet stability and hardness in water are extremely high, because Basa fish consume large amounts of feed, and need to reduce water pollution. The feed formula contains a high proportion of fish meal and soybean meal, so they require equipments that are capable of producing high-protein and high-oil dense pellets.

- Selected Machine: Twin-Screw Floating Fish Feed Pellet Making Machine

3-4 T/H Fish Feed Pellet Making Machine

- Country: Nigeria

- Fish Species: Catfish

- Customer Requirements: The equipment must efficiently process locally abundant yet high-fiber raw materials such as cassava pulp and palm kernel meal. It must also be robust and durable, and it should be suitable for Nigeria’s hot and humid climate and unstable grid voltage.

- Selected Machine: Twin-Screw Floating Fish Feed Pellet Making Machine

1-1.5 T/H Fish Feed Pellet Making Machine

- Country: Bangladesh

- Fish Species: Tilapia

- Customer Requirements: With a limited budget, the customer requires a cost-effective, basic extrusion machine suitable for their farming scale. Local farmers observe fish feeding at the water surface to manage feeding and minimize waste, thus the machine must produce floating feed. It must process common local ingredient formulations primarily consisting of soybean meal, rice bran, and corn, without requiring extremely high fat content.

- Selected Machine: Single-Screw Floating Fish Feed Pellet Making Machine

difference between single-screw floating fish feed making machine and twin-screw floating fish feed making machine

Next, we will discuss the differences between single-screw floating fish feed making machine and twin-screw floating fish feed making machine. The choice of type directly impacts feed formulation, productivity, and final product quality.

single-screw floating fish feed making machine

Single-screw fish feed pellet making machine rely on the friction generated between the rotating screw and the material to push the powder forward. Therefore, it is sensitive to the fat and fiber content of raw materials. High-oil or high-fiber formulations will cause material slippage, which results in unstable output.

- Raw material adaptability: Suitable for processing conventional formulations with high starch content, but with restrictions on raw material fat content. Otherwise, excessive lubrication may prevent pressure buildup.

- Mixing and shearing: Limited mixing capability, shear primarily derived from the fixed screw compression ratio, difficult to adjust. Starch gelatinization degree is typically not as high as that controlled by twin-screw systems.

- Application: Primarily produces conventional floating or sinking fish feeds (e.g., grass carp, tilapia, shrimp feeds). Raw material sources are relatively stable, and fat content is not high.

twin-screw floating fish feed making machine

Twin-screw fish feed pellet making machine consists of two screws that intermesh and rotate simultaneously, which conveys the material in a forward direction. It can handle diverse raw materials, including high-fat, high-fiber, or high-moisture materials, and it is resistant to slippage with excellent stability.

- Raw material adaptability: Capable of easily processing high-fat, high-fiber, and highly viscous raw materials. It provides great flexibility for developing complex specialized feed formulations.

- Mixing and shearing: Excellent mixing performance ensures uniform dispersion of various micro ingredients. Precise control of shear intensity is achieved by replacing and combining screw elements with different functionalities. This process enables higher starch gelatinization, which results in feed with superior stability in water.

- Applications: Primarily produces specialized aquatic feed (e.g., for eels, cold-water salmon and trout, pufferfish, sea cucumbers, etc.). Suitable for customers with extremely high demands on product quality and stability.

Differences Between Dry and Wet Methods in Single -Screw Fish Feed Pellet Making Machine

The primary difference between dry and wet extrusion is that wet extrusion requires an additional boiler for steam heating during drying. In contrast, dry extrusion employs electric heating elements for drying. This distinction directly influences equipment configuration, energy consumption, and the characteristics of the final product.

Dry Extrusion

In dry extrusion, steam is either not added or added very little. The material primarily relies on the mechanical friction heat generated by the screw rotation to increase temperature and pressure, so as to achieve maturation and expansion. The extruded pellets that are produced have a lower degree of expansion and a compact structure. They have more uniform maturity and good stability in water, though typically not as good as wet extrusion products.

- Advantages: low equipment investment, simple operation, no boiler required, stable performance and reliable operation.

- Applications: Small feed mills, Production of standard sinking fish feed with low requirements for maturation.

Wet Extrusion

Before entering the fish pellet machine, the material undergoes tempering at high temperature and high pressure. By the time it enters the extrusion chamber, the material is already in a high-temperature and high-humidity state, so it can be better matured and expanded. Therefore, the output far exceeds that of dry extrusion. The final pellet feed has extremely high expansion with a loose and porous structure. It maintains its shape for a long time in water without disintegrating, and boasts higher digestibility, which is beneficial for fish digestion and absorption.

- Advantages: High-quality and consistent fish feed, high energy efficiency, high output, and excellent digestibility.

- Applications: The first choice for modern aquatic production, particularly suitable for manufacturing premium floating fish feed and feeds requiring high gelatinization and stability.

Other Major Equipment in the Complete Fish Feed Pellet Production Line

A complete modern fish feed production line is a complex system project that includes the full range of equipment from raw material reception to finished product packaging. Its core objective is to efficiently produce high quality feed that meets the nutritional requirements of fish and exhibits excellent stability in water.

Primary cleaning screen

It is mainly used to remove large impurities such as hemp ropes, stones, and paper scraps from raw materials.

Magnetic separator

It is used to remove metallic impurities such as nails and screws from raw materials, which protects subsequent crushing and pelleting equipment from damage.

Feed Crusher

The water-drop hammer mill is commonly used for its high efficiency and uniform particle size. For fish feed, finer raw material particle size is required to enhance feed digestibility and pellet formation quality.

Feed Mixer

Twin-shaft paddle mixers are commonly used, capable of uniformly blending various ingredients in a short time to ensure consistent nutritional content in every feed pellet.

Feed Dryer

To minimize particle breakage, multi-layer mesh belt dryers are commonly used after granulation. These dryers utilize hot air to reduce moisture content in the pellets to approximately 13%.

Oil Sprayer

Uniform spraying of heat-sensitive liquid nutrients such as fish oil, phospholipids, and vitamin solutions onto the surface of cooled pellets significantly enhances the energy content and palatability of feed.

Cooling Machine

As aquatic feed require high water resistance, cooling should not be too rapid. Therefore, counter-flow coolers are typically used to reduce pellet temperature to near room temperature with ambient air, thereby fixing their structure and preventing mold growth.

Vibrating Screen Classifier

It screens cooled particles, and utilizes the vibrating screen to classify mixtures of different particle sizes, which separates qualified products from powder and oversized particles.

Why Choose RICHI Machinery

RICHI Machinery not only provides you with advanced equipment but is also committed to becoming your trusted long term partner. We are dedicated to creating value for your feed production business through our extensive experience, professional expertise, and sincere service. Let’s work together to achieve mutual success in the future.

Highly experienced

Since 1995, RICHI Machinery has focused on the feed machinery manufacturing sector, evolving into an international enterprise integrating research, development, production, sales, and service. Over the past three decades, we have accumulated extensive industry experience, with a service network spanning 109 countries and regions worldwide. Our products are exported to premium markets across the Middle East, South America, Africa, Southeast Asia, and Europe, and have earned widespread trust and high praise from customers globally. We understand that every piece of equipment is central to our customers’ production systems.

Customized Solutions

During the early stages of our collaboration, we will discuss with you to gain a detailed understanding of your raw material characteristics, production objectives, and budgetary constraints. Based on this foundation, we will tailor the most suitable solution specifically for your needs. Whether it’s standard poultry feed production lines or complex aquatic extruding lines, our professional technical team and wide project experience will deliver the cost-effective, stable, and reliable customized solutions. We ensure that the equipment perfectly matches your production requirements.

On-site Installation

After the equipment arrives on site, our professional technical team will arrive on schedule to provide standardized installation and commissioning services. Engineers will strictly adhere to operational standards to ensure that the equipment operates smoothly. We understand that proper usage and maintenance are crucial for ensuring long-term and stable equipment operation. Thus, during the commissioning process, our engineers will provide comprehensive on-site training for your operators and maintenance personnel. This training covers equipment operating procedures and troubleshooting methods for common issues.

Information Sharing

We attach great importance to information transparency. Throughout the production process, we regularly update you on progress via photos and videos, so you can keep track of your equipment’s manufacturing situation at any time. Once the equipment is completed, our packaging team employs specialized packaging solutions to ensure safe and timely delivery.

Modern Workshop

Our modern production workshop is equipped with advanced machining centers and CNC equipment, which realizes intelligent and standardized production processes. From material cutting, welding, machining to packaging, every step strictly adheres to the quality management system to ensure each piece of equipment meets high standards of precision and durability. All products have obtained international certifications including ISO, CE, SGS, and BV, so you can purchase with no worries.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond and will first try to resolve it remotely by phone or video. If the problem cannot be resolved remotely, we will dispatch professional technical staff to repair it on site within 24 hours in order to minimize the impact of downtime on your production.

FAQ Of Fish Feed Pellet Making Machine

What types of aquatic feed can a floating fish feed pellet making machine primarily produce?

+

Covers nearly all aquatic species, such as:

- Floating fish feed: For bass, trout, catfish, ornamental fish, etc.

- Sinking feed: For carp, grass carp, shrimp, crab feed, etc.

- Slow-sinking feed: For large yellow croaker, flatfish, etc.

- Specialized feed: Such as extruded powder feed and starter feed for eels, soft-shelled turtles, etc.

How to adjust the buoyancy of the fish feed?

+

The buoyancy of fish feed is primarily determined by both formulation and extrusion process:

1. Formulation factors: Higher starch content promotes floating. Higher fat and fiber content promotes sinking.

2. Process factors:

- Floating materials: Increase extrusion temperature, enhance mechanical friction, reduce discharge moisture.

- Sinking materials: Lower extrusion temperature, reduce mechanical friction, increase discharge moisture, increase die hole diameter and length-to-diameter ratio. Post-extrusion conditioning or drying time may sometimes be required.