Goat Feed Pellet Making Machine

The RICHI goat feed pellet making machine is a specialized machine that transforms mixed sheep feed materials( For example, pasture grass, straw, and concentrate feed) into pellets through high-temperature and high-pressure extrusion.

Production Of Goat Feed Pellet Making Machine

RICHI offers customized sheep feed pellet machines with capacities ranging from 1 to 45 tons per hour to meet diverse requirements.

With the increasing scale of sheep farming, many breeders face challenges such as high feed costs and management difficulties. If feed formulations are unscientific, it can lead to feed wastage and poor growth in the flock, further increasing the pressure of costs. The growing number of sheep also makes disease prevention and herd management more complex. The goat feed pellet making machine offers a solution to solve these difficulties.

The RICHI goat feed pellet making machine is a specialized machine that transforms mixed sheep feed materials into pellets through high-temperature and high-pressure extrusion. This process not only alters the physical form of the feed but also improves the quality of the feed through maturing.It can enhance feed utilization, reduce waste, and be easy to store and transport. It also can eliminate some harmful microorganisms during the pelleting process, which reduces the risk of disease in sheep and promotes their healthy growth. Because of the robust construction and key components made from wear-resistant materials, the machine delivers excellent stability, low failure rates, and a very long service life, which is the preferred equipment for many professional sheep feed manufacturers.

Classification Of Goat Feed Pellet Making Machine

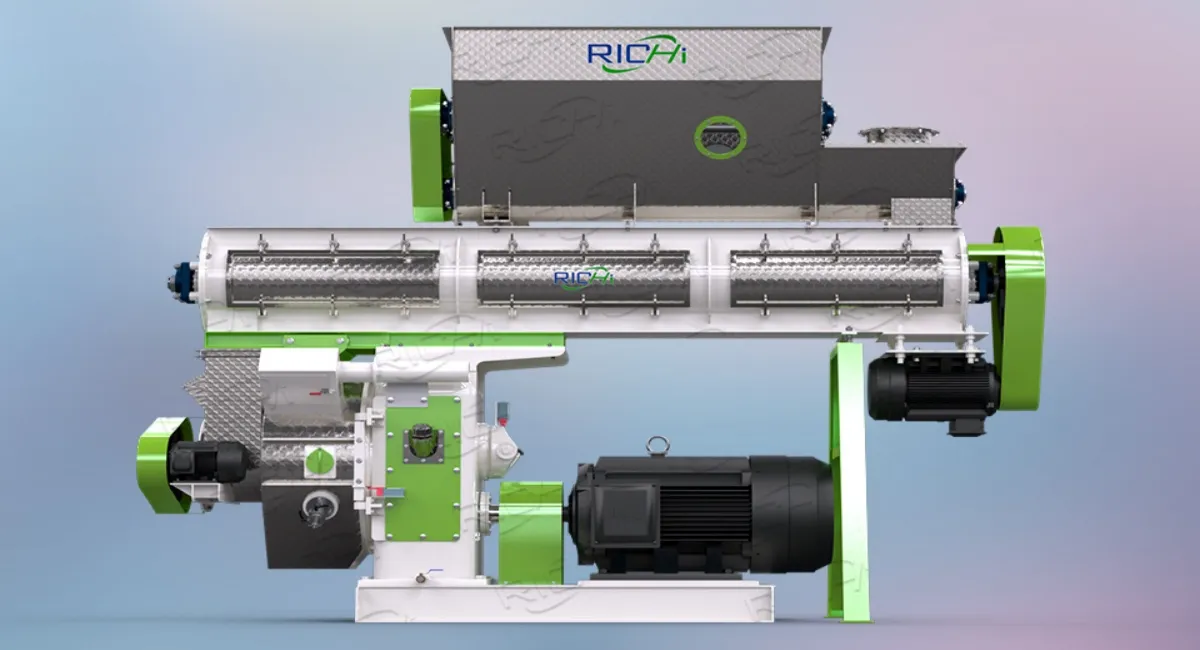

RICHI goat feed making machine are classified into two types: one is SZLH series goat feed pellet making machine, and the other is CZLH series goat feed pellet making machine specifically designed for ruminants.

SZLH Series Goat Feed Pellet Making Machine

RICHI Machinery’s SZLH Series Goat Feed Pellet Making Machine not only can produce sheep feed pellets but also is suitable for manufacturing feed pellets for poultry, livestock, ruminants, aquatic animals, and other animal feeds. When feed formulations primarily consist of grains such as corn, wheat, and soybean meal, we recommend selecting the SZLH series sheep feed pellet machine. This equipment can achieve higher grinding fineness and greater pellet density.

CZLH Series Goat Feed Pellet Making Machine

RICHI Machinery’s CZLH Series Goat Feed Pellet Making Machine is only designed for producing ruminant animal feed pellets primarily from grass meal and raw grains. When the raw material primarily consists of high-fiber formulations such as straw, alfalfa, and pasture grass, a feed pellet mill with greater compression capacity is required. It is recommended to select the CZLH series sheep feed pellet machine.

RICHI MACHINERY

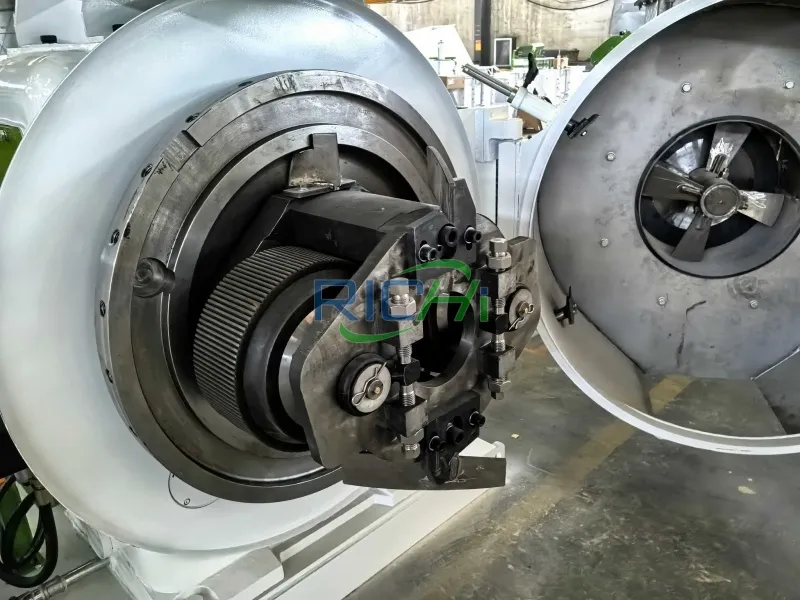

Core Components Display

The core components of a goat feed pellet making machine form the foundation for its efficient and stable operation. These components work together to accomplish the task of compressing powdered feed into pellets.

Test Run Video

The goat feed pellet making machine is specifically designed for modern goat farms and animal feed mills, it meets the feed production needs of goats at different scales and growth stages. We can see that the RICHI goat feed pellet making machine produces pellet feed with a smooth surface, uniform size, and good formation.

RICHI MACHINERY

Working Principle

The production process of the RICHI goat feed pellet making machine can be divided into four key steps: feeding, conditioning, pelleting and cutting, which converts powdered feed ingredients into high density pellet feed.

Feeding

Powdered compound feed is uniformly and steadily conveyed into the conditioner by the feeder according to the preset output. The sheep feed pellet machine employs intelligent control to automatically adjust the feeding rate, which ensures that different types of feed powders are mixed proportionally.

Conditioning

Within the conditioner, the material mixes thoroughly with directly injected steam. This process makes it easier to extrude into shape, and thus reduces wear on the ring die and press rollers as well as lowers energy consumption. The feed after heat treatment also develops an aroma, which increases sheep’s interest in eating.

Pelleting

The pelleting chamber features a ring die driven by a motor to rotate at high speed, which works in conjunction with two fixed internal rollers. Under the combined pressure and friction from the rollers and ring die, the raw material is compressed and shaped within the die holes, then extruded out through the outer surface of the ring die.

Cutting

The extruded cylindrical strands from the ring die are cut into required lengths by the cutting device. The rotational speed of the cutter is adjustable, and the final pellet length can also be controlled by adjusting the distance between the cutter and the outer surface of the ring die.

How to choose an appropriate sheep feed pellet mill?

Selecting an appropriate feed pellet machine is a significant investment decision that requires comprehensive consideration of multiple factors.

1.Determine production scale and capacity requirements

- To meet self-use needs: daily output within 1-2 tons.

- For medium-scale operations: daily output of 5-10 tons.

- For commercial production: daily output exceeding 10 tons requires large-scale automated production lines.

2.Specify raw material composition

If the feed primarily consists of refined ingredients like corn and soybean meal, goat feed pellet making machine can handle it effectively. If the feed mainly comprises coarse materials such as alfalfa meal or straw meal, it is necessary to select a machine with high roller pressure and a high die hole compression ratio.

3.Inspect the machine’s core components

Even within the same machine type, quality can be much different. It is best to choose materials made of high-quality alloy steel and opt for branded motors and bearings whenever possible, such as Siemens motors and SKF bearings.

4.Determine Suppliers and After-Sales Service

It is important to cooperate with a factory specializing in the production of sheep feed pellet mill. If possible, it is the most direct way to test the machine’s performance by bringing raw materials for an on-site test run. Additionally, we should confirm whether after-sales service, training, and warranty services are provided.

Specifications Of Goat Feed Pellet Making Machine

The goat feed pellet making machine features high output and low energy consumption, primarily designed for processing sheep feed pellets in medium to large-scale feed mills. Below are the specifications for the SZLH series sheep feed pellet machine and the CZLH series sheep feed pellet machine. If you’re unsure about selection, please contact us directly.

| SZLH Series Goat Feed Pellet Making Machine | ||||||||

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Main Motor Power (KW) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Modulator Power (KW) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Die Inner Diameter (MM) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellet Diameter (MM) | 2-12 | |||||||

| Output (T/H) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

| CZLH Series Goat Feed Pellet Making Machine | ||||||

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power (KW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-breaking Feeder Power (KW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced feeder power (KW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (MM) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished particle diameter (MM) | 4-12 | |||||

| Output (T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4.0-5.0 | 6.0-8.0 |

The lower the forage content in goat feed, the higher the output of the goat feed pellet making machine. This is because grass meal typically has high fiber content. When passing through the die holes of the ring die, these long fibers generate significant friction, which prevents the material from passing through smoothly. Therefore, under the same conditions, the output of CZLH Series Goat Feed Pellet Making Machine is lower than that of SZLH Series Goat Feed Pellet Making Machine.

Advantages of Goat Feed Pellet Making Machine

Goat feed pellet making machines compact traditional powdered or mixed feed into pellets, which brings multiple significant advantages to sheep farming.

Convenient for Storage and Transportation

Pelleted feed has a 1.5 to 2 times higher density than powdered feed, thus we can save a lot of space during storage and transportation. A single vehicle can carry more feed, so the transportation cost is reduced. At the same time, pelleted feed is less prone to clumping and mold growth, so it has a longer shelf life.

Shortening the Farming Cycle

Due to improved nutrient absorption efficiency and more regular feeding, the growth rate of the sheep flock has significantly accelerated, with weight increasing at a steady pace, which improves the commercial value of the farming products.

Wide Applicability

RICHI sheep feed pellet machine can not only produce pellets for sheep of different types and growth stages, but also produce pellet feed for various animals such as chickens, ducks, pigs, and cattle.

Improving Feed Quality

As ruminants, sheep have strict dietary requirements for the balance of crude fiber and concentrate feed. Pelleted feed tightly binds all ingredients, which completely solves the grading issues caused by varying densities in powdered feed. This ensures every mouthful provides sheep with nutritional feed, and avoids nutritional imbalances caused by selective eating.

Improving Appetite

Tempering during pelleting will make the starch gelatinize, which produces a light aroma that significantly boosts the appetite of sheep. For some ingredients that are nutritionally valuable but have poor appetite, the acceptability of sheep will also be greatly increased after being made into pellets.

High Level of Automation

Equipped with an automatic system including feeding, tempering and pelleting, its simple operation significantly reduces the labor costs and time costs, which is especially suitable for large-scale sheep farms.

Case Study Of Goat Feed Pellet Making Machine

RICHI goat feed pellet making machines and the goat feed production lines have earned the trust and recognition of global customers through the stable performance. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe. RICHI has not only received high praise from numerous customers for its efficient pelleting results but has also successfully established a premium brand image for Chinese manufacturing in the international market through comprehensive after-sales service and technical support.

2T/H Goat Feed Pellet Making Machine

- Country: Germany

- Time: 2024

- Model: SZLH250 Sheep Feed Pellet Machine

- Primary Raw Materials: Corn stalks, wheat straw, soybean meal, alfalfa, etc.

- Background: The customer required the goat feed making machines that the feed mill purchased are capable of producing customized feed according to the needs of livestock farmers. The feed mill provides feed for different animals such as sheep, cattle, and pigs, which requires different raw materials. Therefore, the SZLH series sheep feed pellet machine with a wide range of applications was selected.

10T/H Goat Feed Pellet Making Machine

- Country: Australia

- Time: 2024

- Model: CZLH420 Sheep Feed Pellet Machine

- Primary Raw Materials: Corn, wheat, soybean meal, alfalfa meal, etc.

- Background: A large sheep farm raises thousands of Merino and meat sheep. The farm extensively plants alfalfa and ryegrass, with the goal of utilizing self-produced raw materials to reduce feed costs and produce pellet feed that is durable for storage, convenient for transportation, and easy to feed.

10-12T/H Goat Feed Pellet Making Machine

- Country: France

- Time: 2025

- Model: SZLH420 Sheep Feed Pellet Machine

- Primary Raw Materials: Farm-grown organic barley, peas, fava beans, sunflower meal, organic carrot pulp, beet pulp, etc.

- Background: A French feed processing plant specializing in ruminant feed supplies commercial pellet feed to lamb fattening farms and breeding sheep farms across multiple surrounding regions. With a diverse product line, it demands high pellet hardness and durability.

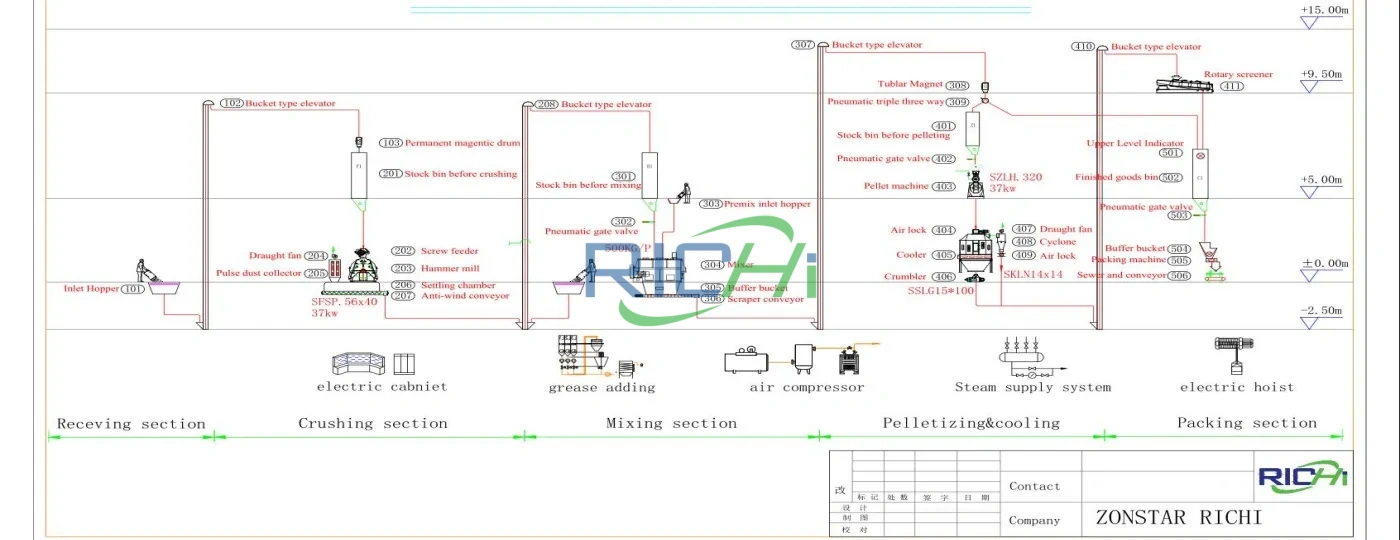

Goat Feed Production Line

RICHI goat feed pellet making machines offer capacities ranging from 1 ton per hour to 45 tons per hour, suitable for sheep feed pellet production lines with outputs of 1-72T/H. Below is the process flow for a 3-4 T/H ruminant feed pellet production line.

1.Cleaning Stage

Corn, soybean meal, bran, grass powder, premix, and other raw materials are cleaned through a material separation screen. This process removes impurities such as hemp rope and stones to protect downstream equipment.

2.Crushing Stage

Larger raw materials (such as corn and grains) require grinding in a crusher to achieve an appropriate particle size, which is beneficial for sheep digestion and absorption. Particles that are too coarse are difficult to form into pellets, while particles that are too fine can impair the sheep’s rumination function.

3.Mixing Process

The crushed ingredients must be thoroughly mixed with a feed mixer to ensure the final feed pellets are nutritionally balanced, which promotes healthy growth in animals. This approach ensures optimal pellet formation in the goat feed pellet making machine while also making the raw materials easier for animals to digest and absorb.

4.Pelleting Stage

The mixed powder enters the conditioner. Under high temperature and pressure, the powder is thoroughly blended. It then enters the pelleting chamber, where material is forced through a ring die by rollers under great pressure. Finally it comes to compact cylindrical pellets.

5.Cooling Stage

Freshly produced feed pellets are highly warm and moist, which can not be immediately bagged as it may cause pellet breakage. Thus, a cooler is used to cool the pellets to room temperature, so that the pellets become hard and suitable for storage.

6.Screening Stage

The cooled pellets contain some powder and undersized particles. These are separated by a vibrating screen. Qualified pellets will go to the next process, while powder is returned to the goat feed making machine for reprocessing. Oversized particles are either sent back to the crusher or discarded as waste.

FAQ About Goat Feed Pellet Making Machine

Raw Materials for Goat Feed Pellet Making Machine

+

The raw materials for goat feed pellet making machine are extremely diverse. Typically, multiple ingredients are blended in specific proportions to produce a nutritious pellet feed. These materials can be mainly classified into the following categories:

- 1.Energy Feed (Provides primary energy): Corn, wheat, barley, oats, sorghum, sweet potatoes, potatoes, sugar beets, etc.

- 2.Protein Feed (Provides protein essential for growth): Soybean meal, cottonseed meal, rapeseed meal, peanut meal, fish meal, meat and bone meal, blood meal, yeast meal, etc.

- 3.Roughage (Provides crude fiber and promotes digestion): Corn stalks, wheat straw, rice straw, bean stalks, alfalfa, sheepgrass, ryegrass, oat straw, peanut vines, sweet potato vines, leaf meal, etc.

- 4.Minerals and Additives (Supplement trace elements): Limestone powder, shell powder, dicalcium phosphate, salt, vitamin premix, trace mineral premix, enzyme preparations, probiotics, etc.

Can you offer some sheep feed formulations?

+

Yes, but sheep feed formulations are not fixed. They require scientific ratios according to the sheep breed and growth stage. Below are examples of typical feed formulations for common breeds and different stages. For practical production needs, you can also consult us to provide you with high quality formulations.

- 1.Lambs (Early Fattening Stage): Corn 55%, Soybean Meal 20%, Bran 12%, Rapeseed Meal 8%, Limestone Powder 1.5%, Dicalcium Phosphate 1.2%, Salt 1%, Premix 1% (providing trace elements and vitamins).

- 2.Lambs (Late Fattening Stage): Corn 60%, Soybean Meal 15%, Bran 10%, Cottonseed Meal 10%, Limestone Powder 1.5%, Dicalcium Phosphate 1.2%, Salt 1%, Premix 1%, Baking Soda 0.3% .

- 3.Breeding Ewes (Early Gestation): Corn 50%, Soybean Meal 10%, Bran 18%, Peanut Straw Meal or Alfalfa Meal 15%, Cottonseed Meal 5%, Limestone 1.5%, Salt 1%, Premix 1%.

- 4.Breeding Ewes (Early Gestation and Lactation): Corn 55%, Soybean Meal 22%, Bran 10%, Alfalfa Meal 8%, Limestone Powder 2.0%, Dicalcium Phosphate 1.5%, Salt 1%, Premix 1%.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.