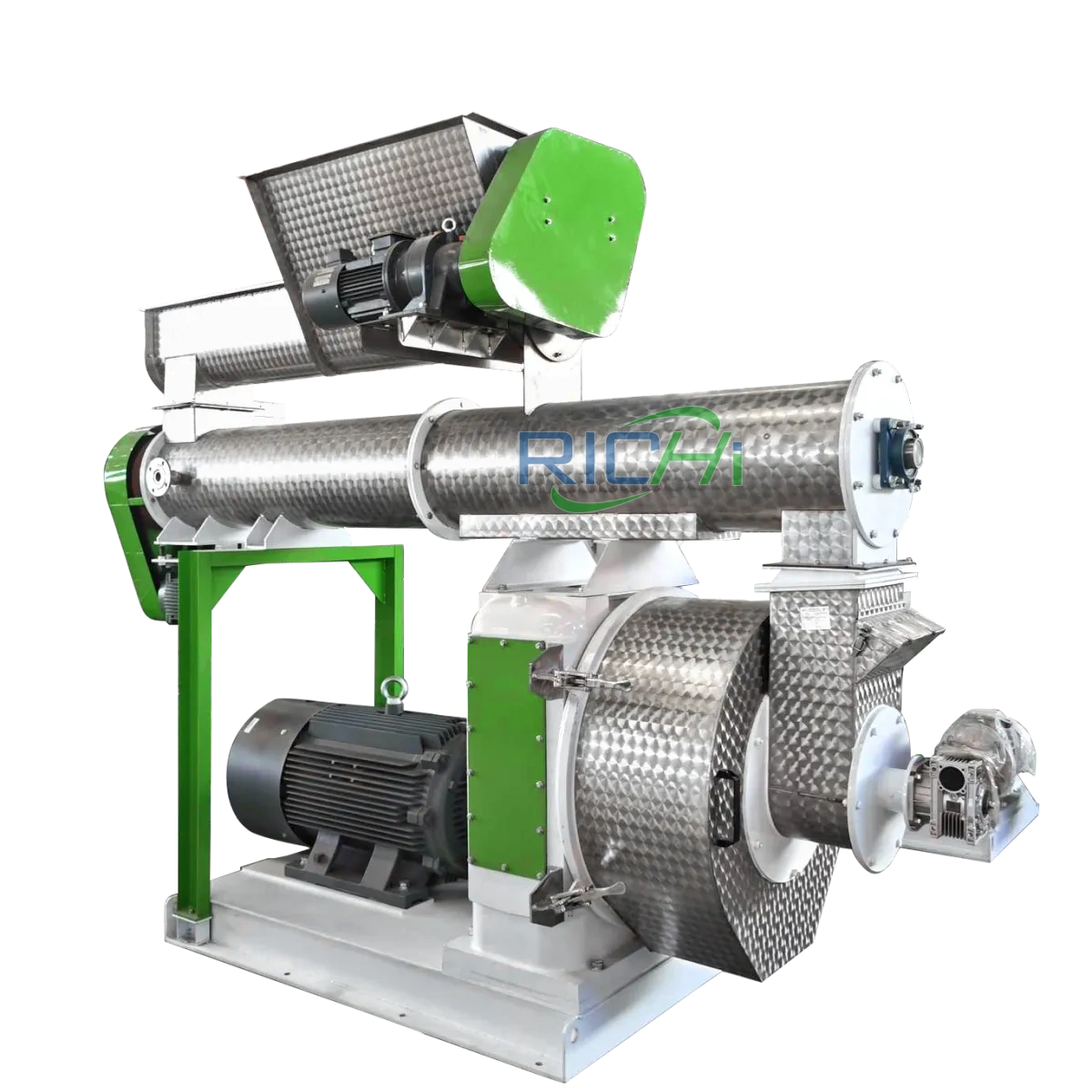

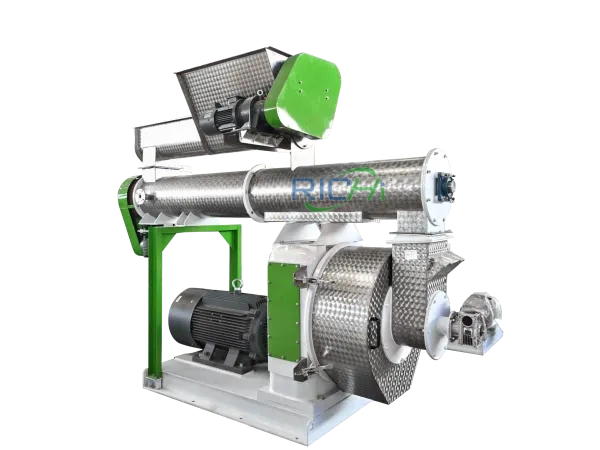

Hay Pellet Machine For Sale

RICHI hay pellet machine for sale compresses agricultural waste such as straw and forage into high-value fuel pellets or feed pellets that are easy to store and transport.

Hay Pellet Machine for Sale

This machine is not only an eco-friendly device for processing waste but also a tool for enhancing hay value.

Hay pellet machine for sale is an innovative agricultural machine that uses physical compression to transform loose agricultural waste such as straw and hay into high-density and uniformly shaped cylindrical pellets.

RICHI hay pellet machine for sale solves the challenge of processing waste materials like forage and hay. The original bulky hay is difficult to transport and store, so they may be burned. After processing through a hay pelletizer, its volume is reduced to one-fourth of the original size, which greatly lowers storage and transportation costs and eliminates environmental pollution caused by burning at its source. Hay pellet machines for sale are widely used in large farms, livestock breeding operations, and specialized biomass fuel processing plants. For every customer, it means transforming low-value hay into marketable high-value commodities, thereby reducing production costs while opening new profit channels. Therefore, this makes it an ideal piece of equipment for promoting sustainable agriculture and achieving a circular economy.

Videos Of Hay Pellet Machine For Sale

Working Principle of Hay Pellet Machine For Sale

The working principle of the hay pellet machine for sale involves the physical process of compressing loose hay powder through mechanical pressure, friction-generated heat, and the material’s inherent physical changes. This process forces the material through a specific die, which converts it into high-density pellets. The entire process is divided into four distinct stages.

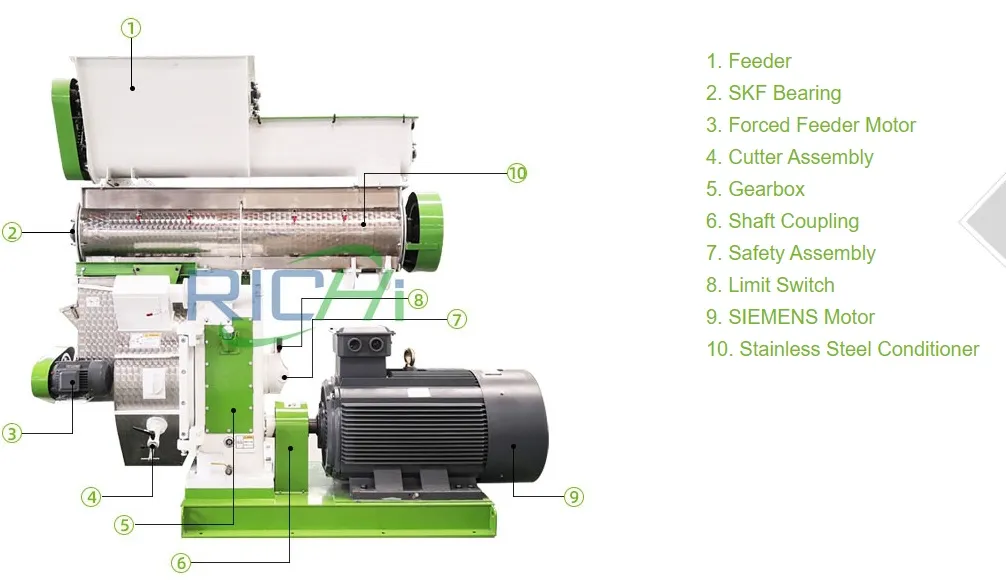

Compression

The crushed hay powder is fed between the ring die and the press rollers. As the main shaft drives the ring die to rotate at high speed, the immense centrifugal force and the material’s own friction cause the press rollers to rotate in the opposite direction. During this process, the material undergoes dramatically increased compression.

Conditioning

The combined effect of the continuous injection of steam and mechanical friction causes the temperature of the material to rise sharply over a short period of time. Then this heat softens the lignin in hay meal, which melts at high temperatures and acts as a natural binder.

Forming

Under immense pressure, the softened and initially bonded material is forcibly extruded through the die holes in the ring die. This high-pressure extrusion process involves generating high temperatures through friction. This causes natural binders like lignin to undergo complete plasticisation, which forms dense cylindrical strands.

Cutting

Fixed blades installed externally on the ring die cut the continuously extruded hay strips into pellets of a predetermined length. This convert infinitely long strip materials into standardised granular products of uniform dimensions for convenient packaging and use.

Why Make Hay Pellets?

Although the modern feed industry is highly developed, hay remains an indispensable component of livestock feed as the most fundamental roughage. Additionally, hay pellets can be used not only as feed but also as a biomass fuel for combustion, which is an environmentally friendly energy source. The processed pellets have two primary applications:

1.As high-quality animal feed

- During the pelleting process, vitamins, minerals, protein supplements, and other ingredients can be uniformly added to produce nutritionally balanced feed, which ensures balanced nutrient intake.

- During the high-temperature and high-pressure pelleting process, the starch in the raw materials undergoes gelatinization, thus enhancing the digestibility and absorption rate of the livestock.

- The pelletized form prevents livestock from selectively eating only their favorite parts of the mixed feed, thereby avoiding nutritional waste.

- Low moisture content and high density of the pellets minimize surface area exposed to air, which solves the problem of mold growth during hay storage.

2. As clean energy source

- Hay pellet fuel offers stable calorific value and complete combustion, so it can replace coal for heating or industrial boilers. As a clean energy source, it enables the circular utilization of agricultural resources.

- By converting agricultural waste into energy, we can avoid the severe air pollution and loss of soil organic matter caused by direct field burning.

- Loose hay occupies a large volume, resulting in high transportation and storage costs. When compressed into pellets, its energy density increases significantly, and approaches that of coal, which makes it more convenient for long-distance transport and centralized storage.

Hay Pellet Making Machine Models and Specifications

RICHI hay pellet machines for sale have various models. Below are the most common models and their specifications. Additionally, we can customize hay pellet making machines to meet individual customer requirements.

CZLH320 Hay Pellet Machine For Sale

- Production Capacity: 0.5-0.6 T/H

- Main Motor Power: 22 kW

- Arch-Breaking Feeder Power: 2.2 kW

- Forced Feeder Power: 0.75 kW

- Ring Die Inner Diameter: 320 mm

- Finished Pellet Diameter: 4-12 mm

CZLH350 Hay Pellet Machine For Sale

- Production Capacity: 1.0-1.2T/H

- Main Motor Power: 37 kW

- Arch-Breaking Feeder Power: 2.2 kW

- Forced Feeder Power: 0.75 kW

- Ring Die Inner Diameter: 350 mm

- Finished Pellet Diameter: 4-12 mm

CZLH420 Hay Pellet Machine For Sale

- Production Capacity: 1.8-2.0 T/H

- Main Motor Power: 90 kW

- Arch-Breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Inner Diameter: 420 mm

- Finished Pellet Diameter: 4-12 mm

CZLH520 Hay Pellet Machine For Sale

- Production Capacity: 2.8-3.0 T/H

- Main Motor Power: 132 kW

- Arch-Breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Inner Diameter: 520 mm

- Finished Pellet Diameter: 4-12 mm

CZLH678 Hay Pellet Machine For Sale

- Production Capacity: 4-5 T/H

- Main Motor Power: 185 kW

- Arch-Breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Inner Diameter: 678 mm

- Finished Pellet Diameter: 4-12 mm

CZLH768 Hay Pellet Machine For Sale

- Production Capacity: 6-8T/H

- Main Motor Power: 250 kW

- Arch-Breaking Feeder Power: 4 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Inner Diameter: 768 mm

- Finished Pellet Diameter: 4-12 mm

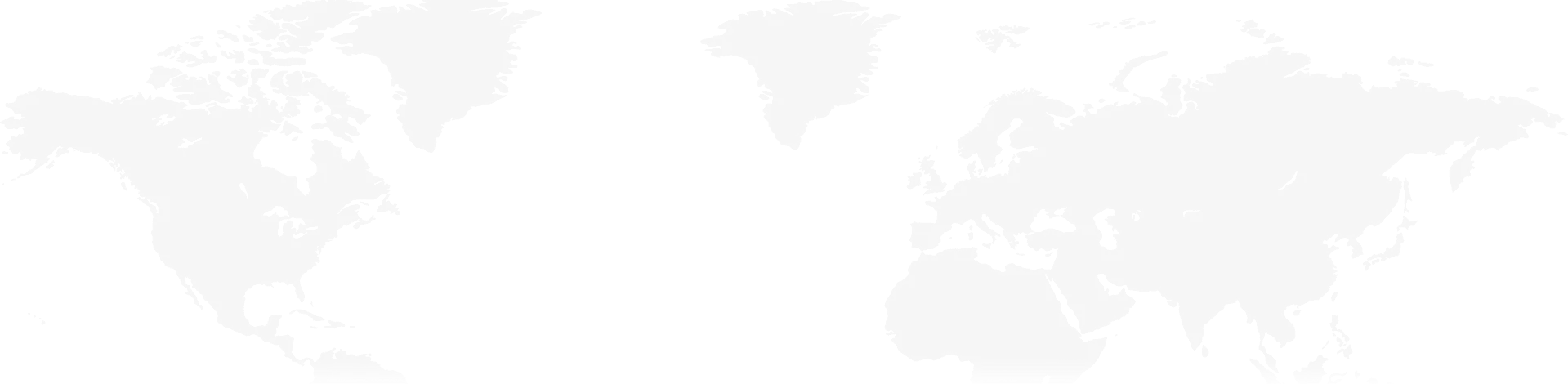

Features of the Hay Pellet Machine For Sale

The hay pellet machine for sale processes powdered hay products into pellets through the combined action of heat, moisture, and compression.

- The entire machine’s transmission system utilizes premium SKF bearings, so it has stable construction and extended service life.

- The main cabinet is constructed from high-quality cast steel components with uniform thickness and a compact structure, which provides enhanced support for normal operation.

- Equipped with a safety pin that provides overload protection by breaking if the main motor overloads.

- Features a Siemens motor to ensure that the Hay pelletizer maintains stable production efficiency over a long period.

- The main drive system utilizes gear transmission for high efficiency, with an output 15% higher than belt-driven models.

- The ring die and pressure roller are made of stainless steel, which is nearly ten times more wear-resistant than the general heat treatment process, so it can greatly save the production cost.

- This machine has an excellent granulation pass rate of over 95%. It also can accommodate a wide range of formulations and allows to adjust the granule size by replacing the ring die.

Ring Die

Feeding system

Conditioner

Cutting Device

Precautions for Producing Hay Pellets

Producing high-quality hay pellets is a systematic process where not only the machinery itself but also operational techniques and raw materials play crucial roles. As a manufacturer specializing in hay pellet machine sales, RICHI can share some secrets to successful production.

Raw Material Selection and Combination

- Avoid the use of a single feed ingredient for a long period: Mix different types of grasses (such as hay and forage) or straws (such as rice straw and wheat straw) as much as possible. This helps balance nutrition and improves pellet formation.

- Fiber content must be controlled: Because excessive fiber will cause excessive wear on dies and reduces the output of hay pellet mill.

- Ensure uniform pellet size as much as possible: Non-uniform particle size leads to loose structure and increased breakage. Excessively coarse particles result in rough surfaces, easy breakage and higher energy consumption of the hay pellet mill.

- Control moisture content: Adjusting the moisture content of raw materials to between 13% and 18% would be a safe range. The specific optimal value varies depending on the raw material and equipment, so it requires subsequent experimentation to determine.

Machine Commissioning and Operation

- Cold Start: Conduct test runs with oily materials such as bran mixed with grease to preheat the rollers and molds. This prevents damage to the dies and rollers and helps achieve optimal operating temperatures.

- Select the correct mold cavity compression ratio: Different raw materials require dies with varying compression ratios. Fibrous materials such as grass powder and straw typically demand higher compression ratios (e.g., 1:8 or greater) to generate sufficient pressure for proper molding.

- Moisture-proof Storage: While finished pellets are resistant to mold, they may still absorb moisture. So they should be stored in a dry and well-ventilated warehouse which is protected from rain. It is also recommended to use woven bags lined with plastic bags for sealed packaging.

Hay Pellet Machine Project Case Study

At present, RICHI hay pellet machines for sale have been exported to over 70 countries worldwide, with the number of projects continuing to grow. As essential equipment for ruminant feed pellet plants and wood pellet manufacturing plants, RICHI hay pellet mills for sale have become the preferred choice for numerous customers.

12 T/H American Hay Pellet Making Machine Project

4 T/H Uzbekistan Hay Pellet Machine For Sale

5 T/H South African Hay Pellet Machine For Sale

10 T/H Australian Biomass Pellet Production Line

10 T/H French Ruminant Feed Pellet Production Line

20 T/H American Livestock Feed Pellet Production Line

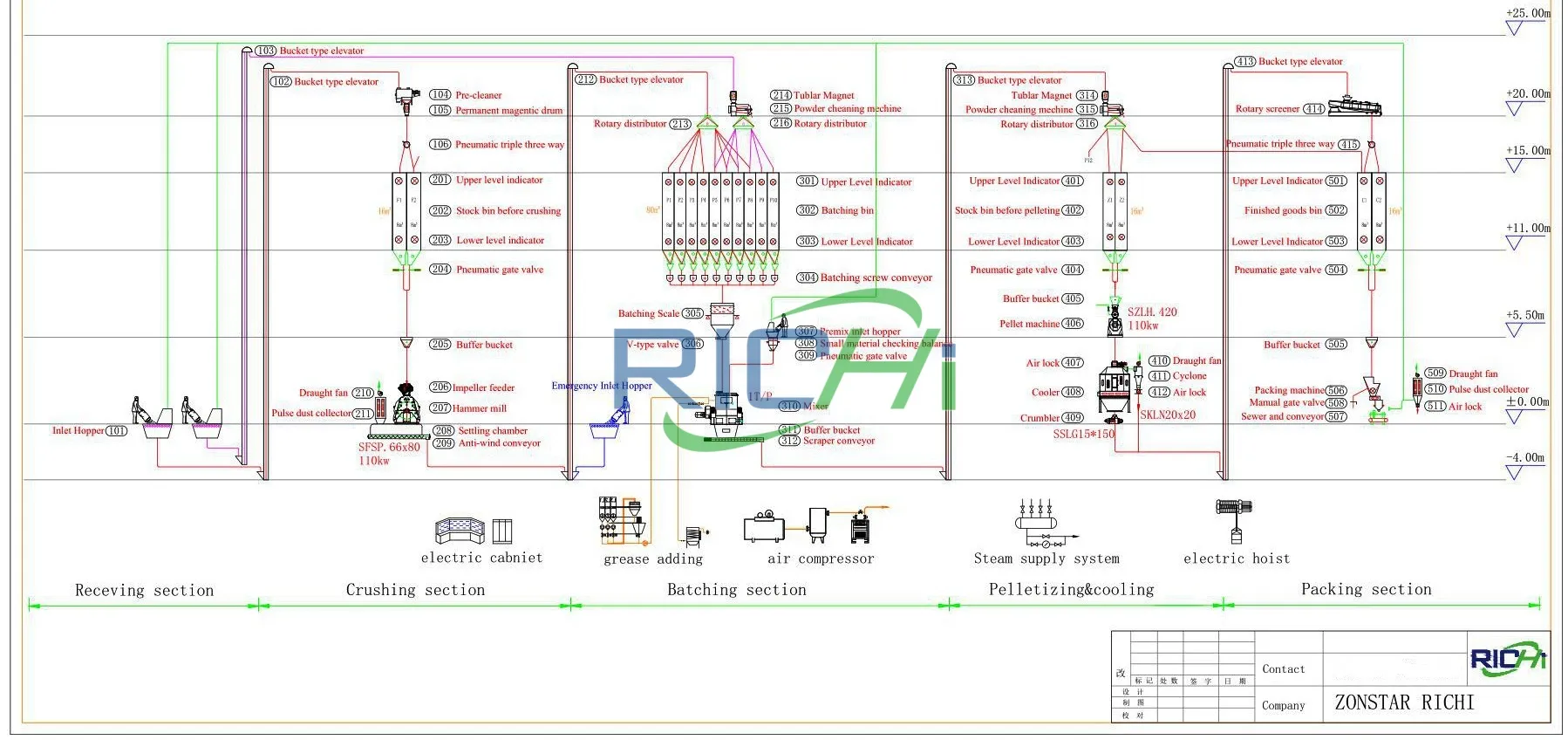

Hay Pellet Production Line Working Process For Large Capacity

RICHI Machinery not only offers hay pellet machines for sale but also provides complete straw pellet plant. This production line can also be used to manufacture hay pellets, straw pellets and specialized feed pellets for ruminants, which can meet diverse market demands. Below is a detailed explanation of the core process flow for the 8-12T/H hay pellet production line.

1

Raw Material Crushing—Hay Crusher

A specialized bale-breaking crusher is used to chop long-stemmed hay into 1-3 cm segments. This reduces material volume prepares it for subsequent fine grinding, and also ensures smooth feeding.

2

Drying Stage— Drum Type Dryer

Hay sections with high moisture content are fed into the drum type dryer. Inside the drum, the material comes into full contact with high-temperature hot air, which quickly evaporates excess moisture. So this process brings the material to a uniform and safe moisture content suitable for granulation.

3

Raw Material Crushing—Hammer Mill

After drying, the hay segments are fed into a hammer mill, where high-speed rotating hammers strike them into finer grass powder. The objective is to crush the raw material to a smaller particle size, which is crucial for subsequent conditioning and pelletizing. Therefore, this forms the foundation for ensuring pellet quality and production yield.

4

Pelletizing Process—Grass Pellet Mill

The tempered material is continuously and uniformly fed into the ring die chamber of the pellet mill. Under immense mechanical pressure, the material is forcibly squeezed through the die holes by the rollers, which forms dense cylindrical strands. These strands are then cut by external blades into pellets of a predetermined length.

5

Cooling System—Counter-flow Cooler

Pellets emerging from the Hay pellet mill are hot and soft, so they should be immediately fed into the counter-flow cooler. Cold air rapidly cools them to room temperature. This process sets the pellets’ shape, reduces moisture content, and hardens them for easier storage and transportation.

6

Screening Stage—Vibrating Screen

The cooled pellets contain a small amount of powder generated during transportation. They then enter the vibrating screen for separation. The vibrating screen separates qualified pellets and returns the screened fine powder to the conditioner for regranulation, which reduces material waste and improves yield.

7

Packaging Process—Weighing Machines and Automatic Packing Scales

Qualified straw pellets after screening are loaded into woven bags or bulk bags via an automated weighing system, and then sealed. Finally they are transported to the finished goods warehouse for storage.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.

FAQ Of Hay Pellet Machine For Sale

What is a hay pelletizer?

+

A hay pelletizer is a mechanical device that compresses crushed hay, straw, and other agricultural waste into high-density and cylindrical pellets through high-temperature and high-pressure extrusion. These pellets are convenient for storage and transportation, and can serve as high-quality feed or biomass fuel.

What is the primary purpose of producing hay pellets?

+

For feed: Enhance nutrient utilization, prevent selective feeding by livestock, reduce feed waste, and facilitate storage and automated feeding.

For fuel: Convert low-value waste into high-energy-density clean energy to replace coal.

What types of raw materials can RICHI hay pellet machine for sale typically process?

+

It can process various fibrous materials, such as alfalfa, timothy grass, Bermuda grass, rice straw, wheat straw, corn stalks, and certain agricultural byproducts.

What are the requirements for raw materials?

+

Particle size: Materials must be finely ground and usually need to pass through a 3-6mm screen. Uneven particle size affects molding efficiency and pellet quality.

Moisture Content: Typically, raw material moisture must be adjusted to between 13% and 18%. Excessively dry material is difficult to form, while excessively wet material results in soft and moldy pellets.

What is the compression ratio of a die? Why is it important?

+

The compression ratio refers to the ratio of the effective length to the diameter of the die bore.

Raw materials with high fiber content and high lignin levels (such as straw) require a higher compression ratio to generate sufficient pressure for proper molding. Selecting an incorrect compression ratio can result in low output, high energy consumption and poor pellet quality.

Is it necessary to add a binder during production?

+

Generally, there is no need. Lignin in the raw materials softens and melts under high temperature and pressure, which acts as a natural binder. However, for certain materials that are extremely difficult to form, a small amount (1-2%) of natural binders such as starch or molasses can be added to improve the forming effect.