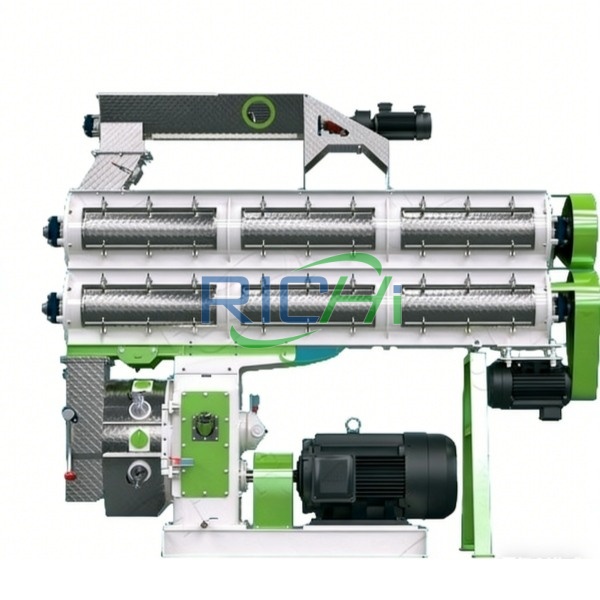

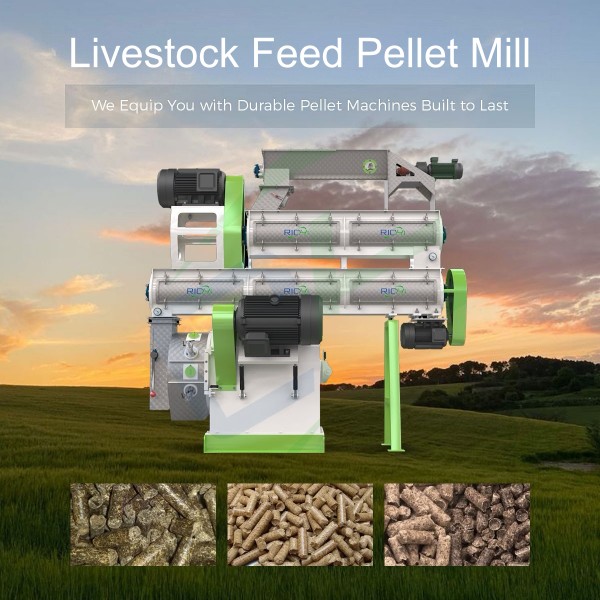

Livestock Feed Pellet Mill For Sale

Livestock feed pellet mill helps you efficiently produce high-quality feed for poultry, cattle, and pigs. Designed for durability and easy operation, it is the perfect solution for your livestock feed production needs. Boost your feed output and save time with our reliable machines.

General Introduction for RICHI Livestock Feed Pellet Mill

RICHI livestock feed pellet mill is a high-performance solution designed to meet the growing demands of modern livestock farming. Engineered for efficiency, durability, and ease of operation, it enables farmers and feed producers to convert raw materials into high-quality pellets for cattle, pigs, and other livestock.

RICHI livestock feed pellet mill offers a full range of production capacities from 1 to 40 tons per hour, making it suitable for a wide variety of livestock feed operations. Whether for medium-scale farms or large feed mills, this machine can meet diverse production needs, allowing farmers and feed producers to scale their operations efficiently.

The machine is widely used in producing feed for cattle, pigs, and other livestock, making it an essential tool in modern livestock farming. By converting raw materials such as corn, soybean meal, wheat bran, alfalfa, and other feed ingredients into high-quality pellets, it helps improve feed efficiency, ensure balanced nutrition, and support healthy growth of livestock.

In addition, RICHI provides comprehensive technical support including installation, operational guidance, and after-sales service, ensuring smooth operation and maximizing the lifespan of the equipment. This makes it an ideal choice for farms and feed mills seeking a scalable, efficient, and reliable solution for livestock feed production.

RICHI MACHINERY

Different Type Livestock Feed Pellet Mill For Sale

RICHI livestock feed pellet mills are specially designed for medium to large-scale farms and feed mills of various sizes. They provide reliable, high-efficiency solutions for producing high-quality feed pellets. No matter the scale of your operation, our feed pellet machines ensure consistent feed quality, optimal production efficiency, and long-term reliability.

Working Video Of Livestock Feed Pellet Mill For Sale

Watch RICHI livestock feed pellet mills in action through our working videos. The videos clearly show the complete feed production process—from raw material input to high-quality pellet output—highlighting the machine’s efficiency, durability, and smooth operation.

Feeding

Raw materials are fed into the pellet mill, ensuring a steady and controlled supply for smooth operation throughout the production process.

Conditioning

The feed passes through the conditioner, where moisture and temperature are adjusted to improve pellet formation and feed digestibility.

Pelleting

Tempered feed is compressed by rollers through a ring die, forming dense and well-shaped pellets suitable for various livestock.

Cutting

Rotating blades cut the extruded pellets to the desired length, ensuring uniform size for easy consumption. Finished pellets are discharged from the machine.

RICHI MACHINERY

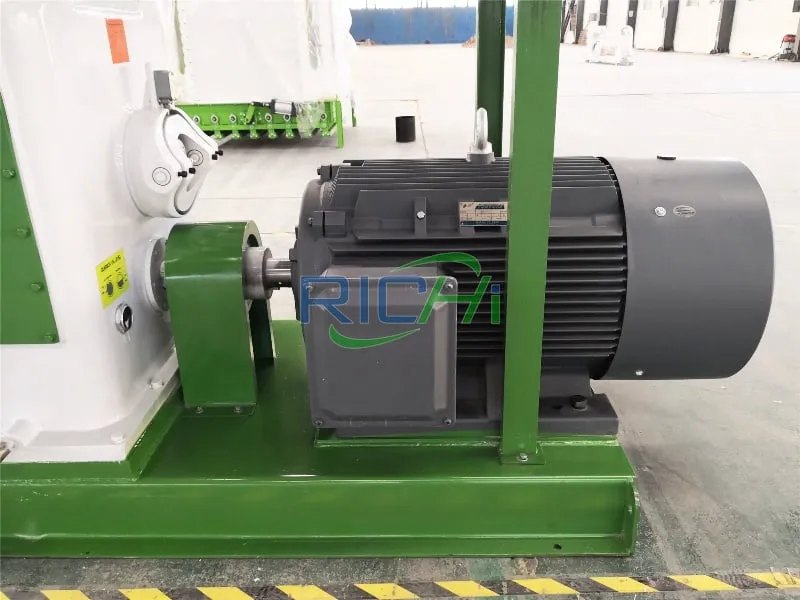

Core Components of Livestock Feed Pellet Mill For Sale

The livestock feed pellet mill is built with high-quality core components to ensure efficient, stable, and reliable operation. Each key part, from the feeding system to the drive mechanism, plays a vital role in producing uniform, durable pellets while reducing downtime and maintenance needs.

Models of Livestock Feed Pellet Mill For Sale

RICHI Machinery offers a wide range of livestock feed pellet mill models to meet different production capacities and farm requirements. From small-scale units to high-capacity mills, each model is designed for reliable operation, efficient pellet production, and easy maintenance.

SZLH250 Livestock Feed Pellet Mill For Sale

- Capacity: 1-2T/H

- Main motor power: 22kw

- Feeder power: 1.1kW

- Conditioner power: 1.5kw

- Price range: 7,000 -10,000$

SZLH320 Livestock Pellet Mill

- Capacity: 3-4T/H

- Main motor power: 37kw

- Feeder power: 1.5kW

- Conditioner power: 2.2kw

- Price range: 15,000 -20,000$

SZLH350 Livestock Feed Pellet Machine

- Capacity: 5-7T/H

- Main motor power: 55kw

- Feeder power: 1.5kW

- Conditioner power: 3kw

- Price range: 20,000 -30,000$

SZLH420 Livestock Pellet Machine

- Capacity: 8-12T/H

- Main motor power: 110kw

- Feeder power: 1.5kW

- Conditioner power: 7.5kw

- Price range: 30,000 -40,000$

SZLH508 Livestock Feed Mill Equipment

- Capacity: 10-18T/H

- Main motor power: 160kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 40,000 -60,000$

SZLH558 Livestock Feed Mill

- Capacity: 15-25T/H

- Main motor power: 180kw /220kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 60,000 -70,000$

SZLH678 Livestock Feed Pellet Mill

- Capacity: 20-30T/H

- Main motor power: 220kw /250kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 70,000 -80,000$

SZLH768 Livestock Feed Pellet Machine For Sale

- Capacity: 25-40 T/H

- Main motor power: 250kw /280kw

- Feeder power: 2.2kW

- Conditioner power: 11kw

- Price range: 80,000 -90,000$

RICHI Livestock Feed Pellet Mill For Sale Global

RICHI livestock feed pellet mill for sale global are supported by more than 30 years of experience in feed processing machinery manufacturing. The equipment has been supplied to customers in over 140 countries and regions, with each project designed according to local raw materials, livestock types, and required production capacity. These global project cases demonstrate how livestock feed pellet mills operate reliably in different production environments and help achieve stable and efficient feed production worldwide.

1-2T/H Livestock Feed Pellet Mill For Sale Nigeria

- Country: Nigeria

- Primary Raw Materials: The main raw materials include maize, maize bran, wheat bran, cottonseed cake, groundnut cake, and small amounts of mineral premix.

- Background: This project is designed for a medium-sized cattle and goat farm in northern Nigeria. The customer wanted to reduce feed costs caused by seasonal shortages of commercial feed and improve feed stability by using locally available raw materials.

3-4T/H Livestock Feed Pellet Mill For Sale Australia

- Country: Australia

- Primary Raw Materials: Typical raw materials include barley, wheat, oats, alfalfa meal, canola meal, and mineral additives.

- Background: The Australian project serves a commercial cattle and sheep farm that requires consistent pellet quality and high production efficiency. The customer focuses on feed nutrition accuracy and long-term operational stability.

6T/H Livestock Feed Mill in Tanzania

- Country: Tanzania

- Primary Raw Materials: Common raw materials include maize, sunflower seed cake, wheat bran, rice husk powder, and mineral supplements.

- Background: The Tanzanian animal feed production line is designed for a regional feed supply center serving multiple cattle and sheep farms. The goal was to improve feed uniformity and reduce dependence on imported feed products.

8-10T/H Indonesia Livestock Feed Pellet Mill

- Country: Indonesia

- Primary Raw Materials: Main materials include corn, rice bran, palm kernel cake, cassava residue, and soybean meal. Due to the high fiber and oil content of some materials, the system was designed with enhanced conditioning and stable feeding.

- Background: This project supports a mixed livestock farm producing feed for cattle, goats, and sheep. The customer needed a flexible production line capable of handling diverse raw materials with varying moisture levels.

20T/H Livestock Pellet Mill For Sale Saudi Arabia

- Country: Saudi Arabia

- Primary Raw Materials: The feed formulation mainly uses imported barley, corn, soybean meal, alfalfa meal, and vitamin-mineral premix.

- Background: This large-scale animal feed factory project in Saudi Arabia serves an industrial livestock operation focusing on cattle and sheep fattening. Due to harsh climate conditions, the customer required a highly stable and automated feed production system.

30T/H Livestock Feed Pellet Machine For Sale US

- Country: US

- Primary Raw Materials: Main raw materials include corn, soybean meal, DDGS, wheat middlings, alfalfa meal, and functional additives.

- Background: The U.S. project is designed for a large commercial feed mill supplying multiple livestock farms. The customer emphasizes high output, standardized production, and long-term continuous operation.

Benefits of Livestock Feed Pellets

Livestock feed pellets offer numerous advantages over traditional mash feed. By improving nutrient utilization, reducing waste, and simplifying storage and feeding, pellets help farmers increase efficiency and support healthier, faster-growing animals.

Improved Nutrient Utilization

Pellets are processed under heat and pressure, which enhances digestibility and reduces anti-nutritional factors.

Animals can absorb more nutrients from each portion of feed, leading to better growth rates and improved feed conversion ratios. This helps farmers maximize the value of their feed ingredients.

Reduced Feed Waste

Dense and uniform pellets are less likely to be spilled, blown away, or left uneaten compared to loose mash.

This reduces overall feed loss and ensures that animals consistently receive the intended nutrient levels, saving money and improving farm efficiency.

Convenient Handling

Pellets are easy to store, transport, and feed due to their uniform size and compact form.

Consistent nutrition in every pellet supports healthier livestock, improves growth rates, and reduces feeding labor. This convenience makes feed management simpler for farms.

Advantages of RICHI Livestock Feed Pellet Mill For Sale

RICHI livestock feed pellet mills combine advanced technology, durable construction, and user-friendly design to deliver high-quality feed pellets efficiently. These mills offer multiple advantages that help farms and feed factories improve production and reduce operational costs.

High Efficiency

Optimized design ensures maximum output with lower energy consumption, reducing overall production costs.

Durable Construction

Made with high-quality materials and precision engineering, the mill provides long service life and stable operation.

Uniform Pellet Quality

Advanced ring die and roller system produce dense, uniform pellets suitable for various livestock.

Easy Operation and Maintenance

User-friendly structure allows simple operation and maintenance, minimizing downtime.

Flexible Capacity Options

Available in a wide range of models, from small-scale to high-capacity mills, meeting different farm and feed mill needs.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 140 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

Tailored equipment and production lines to meet your farm or feed mill’s specific needs.

Modern Workshop

State-of-the-art manufacturing facilities ensure precision, durability, and consistent quality.

On-site Installation

Professional engineers provide installation services on-site for smooth start-up.

Information Sharing

Keep clients updated with technical knowledge, process improvements, and industry trends.

On-the-spot Training

Hands-on training ensures your staff can operate and maintain equipment efficiently.

After-Sales Service

Timely support and maintenance services to minimize downtime and maximize production efficiency.

Frequently Asked Questions About Livestock Feed Pellet Mill For Sale

What livestock can this feed pellet mill be used for?

+

This livestock feed pellet mill is designed to produce feed pellets for a wide range of farm animals, covering both ruminants and non-ruminants commonly raised in medium to large-scale farming operations. It is suitable for cattle, beef cattle, dairy cows, pigs (including piglets, growing pigs, and finishing pigs), sheep, goats, and rabbits. By adjusting feed formulations, pellet diameters, and compression ratios, the pellet mill can meet the nutritional and physical requirements of different livestock at various growth stages.

In addition, the animal feed pellet mill can also be used to produce feed pellets for special livestock such as camels, deer, horses, and donkeys, which often require higher fiber content and specific pellet hardness. With flexible ring dies and adjustable conditioning parameters, the pellet mill can process a wide variety of raw materials, including grains, oilseed meals, forage meals, and agricultural by-products. When combined with suitable auxiliary equipment, it ensures stable pellet quality, good palatability, and efficient feed utilization for different livestock types.

What raw materials can be used to produce livestock feed pellets?

+

A wide range of raw materials can be used to produce livestock feed pellets, including corn, wheat, soybean meal, bran, grass, alfalfa, straw, and various agricultural by-products. RICHI can provide customized solutions for customers whose raw materials require special handling. For example, if the material is difficult to feed uniformly, we can add a forced feeding device to ensure smooth pellet production.

If the raw material is not suitable for direct pelleting, we can suggest combining it with other auxiliary machines, such as hammer crushers or mixers, to optimize particle size and achieve better mixing. Our tailored approach ensures that each type of raw material can be efficiently processed into high-quality livestock feed pellets.

I run a farm with 1,000 cattle, 4,000 pigs, 2,500 sheep, and 1,500 rabbits. Which pellet mill should I choose?

+

For this scale of farming operation, the daily feed requirement can be estimated based on the typical feed consumption per animal:

- Each cow consumes approximately 6 kg of feed per day, so the total requirement for 1,000 cows is 1000*6 = 6,000 kg = 6 tons;

- Each pig consumes approximately 3 kg per day, so 4,000 pigs require 4000*3 = 12,000 kg = 12 tons;

- Each sheep consumes approximately 0.5 kg per day, so 2,500 sheep require 2500*0.5 = 1,250 kg = 1.25 tons;

- Each rabbit consumes approximately 0.2 kg per day, so 1,500 rabbits require 300 kg = 0.3 tons.

Assuming the production line operates for 6 hours a day, the daily required capacity is 6 + 12 + 1.25 + 0.3 ≈ 20 tons. To efficiently meet these needs, the hourly capacity should be approximately 20 ÷ 6 ≈ 3.33 tons.

We recommend choosing the RICHI SZLH320 livestock feed pellet mill, which has a capacity of 3-4 tons, perfectly matching your production needs. This equipment features adjustable pellet size, flexible ring die, and can be used with auxiliary equipment such as hammer mills and mixers to adapt to different raw materials, ensuring smooth production and providing high-quality feed pellets to meet the daily needs of all livestock.

How much does a livestock feed pellet mill cost?

+

The livestock feed pellet mill price ranges from 7,000 to 85,000 USD, depending on factors such as production capacity, model type, raw material characteristics, and whether additional auxiliary equipment is needed.

RICHI provides 1-40T/H livestock feed pellet mill for sale and can offer customized solutions to meet your specific project requirements. Please contact our sales team with your capacity needs, raw materials, and project details for a personalized quote.