Poultry Feed Mill Machine

Poultry feed mill machine refers to a complete poultry feed production line that integrates crushing, mixing, pelleting, cooling, and packaging into one system. It is designed to produce uniform, high-quality poultry feed pellets with stable performance, easy operation, and flexible formulation adjustment for poultry farms and feed manufacturers.

Introduction for Poultry Feed Mill Machine

A poultry feed pellet mill refers to a complete poultry feed production system designed to process raw feed materials into uniform, high-quality pellets. It is widely used in chicken, broiler, layer, duck, and other poultry feed production lines to enhance feed consistency, improve nutrient utilization, and increase overall feeding efficiency.

The poultry pellet machine follows a continuous feed processing workflow, efficiently converting raw ingredients into high-quality poultry feed pellets. The process begins with crushing and batching, followed by precise mixing to ensure uniform nutrient distribution. Mixed materials are then conditioned and conveyed into the pelletizing section, where rollers press them through a high-strength ring die. Dense, uniform pellets are formed, which are then cooled, screened, and packaged to maintain stable quality.

The RICHI poultry feed mill machine is available in flexible system configurations, making it suitable for medium to large poultry farms as well as feed mills of various scales, from regional processing plants to large commercial feed manufacturers.

- Production Capacity: 1-100T/H

- Machine type: Ring Die Feed Pellet Machine

- Applicable Poultry: Broiler chickens, Layer chickens, Ducks, Turkeys, Quails and other poultry

- Pellet Size: Typically 2–6 mm (Pellet size can be customized according to poultry growth stages)

- Poultry Feed Mill Machine Price: $10,000-$2,800,000

Working Video Of Poultry Feed Mill Machine

This video demonstrates the machine running smoothly, producing uniform poultry feed pellets with high efficiency. You can observe the entire pelletizing process, from raw material feeding to finished pellet output, highlighting its stable operation, consistent pellet quality, and ease of use. Watching the machine in operation helps you better understand its performance and suitability for your poultry feed production needs.

Poultry Feed Mill for Different Poultry Feed Production

Our poultry feed mill machine is designed to meet the feeding needs of a wide range of poultry species. Whether you are raising broilers, layers, ducks, turkeys, or quails, this system produces uniform, high-quality pellets that suit different growth stages and dietary requirements. It ensures efficient feed utilization and supports healthy growth across all types of poultry.

Broiler Chicken

Layer Chicken

Ducks

Turkeys

Quails

Goose

Different Poultry Feed Making Machine Price In Production Line

The poultry feed making machine price varies depending on the machine’s role in the production line, its capacity, and level of automation. From small-scale pellet mills to complete feed production systems, each machine is designed to match its performance, durability, and production value. Understanding these differences helps farms choose the right equipment to optimize feed quality and efficiency.

The hammer mill is used to crush raw materials such as corn, wheat, soybean, and other grains into small, uniform particles, which improves mixing efficiency and feed pellet quality. It features a robust design, high crushing efficiency, and easy maintenance. USD

The feed mixer evenly blends crushed raw materials with vitamins, minerals, and other additives, ensuring a balanced and uniform feed formulation. It has a large mixing capacity, high mixing uniformity, and low energy consumption.

Poultry Feed Pellet Machine

The pellet machine compresses the mixed feed into uniform pellets suitable for various poultry species. It features adjustable pellet size, stable operation, and high output. The machine ensures dense, durable pellets with minimal dust, improving feeding efficiency.

The cooler reduces the temperature and moisture of freshly pelleted feed to enhance storage stability and prevent pellet breakage. It operates efficiently, with low energy consumption, and helps maintain pellet hardness and quality.

Vibrating Screen

The vibrating screen separates broken or oversized pellets, ensuring uniform pellet size for final packaging. It improves feed quality consistency and reduces waste, with a simple structure and easy cleaning.

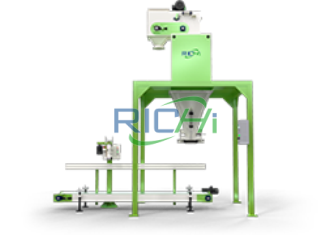

The packing machine automatically measures, fills, and seals feed pellets into bags for storage or shipment. It offers high packing accuracy, fast operation, and can handle a variety of bag sizes.

How To Produce Poultry Feed Pellets?

Producing high-quality poultry feed pellets requires a systematic process that ensures uniform nutrition, easy digestion, and optimal pellet formation. The production involves multiple stages, each designed to improve feed quality and operational efficiency.

The configuration of the production line is closely related to the poultry feed making machine price, as factors such as production capacity, automation level, and optional auxiliary equipment directly affect the total investment. A well-matched equipment setup not only improves feed quality and operational efficiency but also helps optimize costs and ensure stable, long-term production.

Raw Material Crushing

01

Use a hammer mill to reduce raw materials into fine particles, improving mix uniformity and pellet quality.

Batching And Mixing

02

Combine different raw materials and additives evenly in a feed mixer to achieve balanced nutrition.

Pelletizing Section

03

Feed the mixed materials into a pellet machine to form uniform, compact feed pellets of the desired size.

Cooling Section

04

Reduce the temperature and moisture of the freshly pelleted feed using a cooler to maintain shape and extend shelf life.

Screening Section

05

Remove broken pellets and oversized particles to ensure consistent pellet size.

Packing Section

06

Pack the finished feed pellets into bags or bulk containers for storage, transport, and sale.

Related Cases Of The Poultry Feed Mill Machine

With over 30 years of experience, RICHI has successfully delivered poultry feed pellet machines and complete feed production projects to more than 140 countries worldwide. These cases demonstrate the versatility, reliability, and efficiency of our machines in real-world operations. From medium to large poultry farms to commercial feed mills, RICHI machines consistently provide high-quality pellets, stable performance, and cost-effective feed solutions for various poultry species and production scales.

How to Choose the Right Feed Mill Machine For Poultry?

Selecting the right poultry feed mill machine is crucial for ensuring efficient production, high-quality pellets, and a good return on investment. Here are the key factors to consider:

1

Total Plant Capacity Planning: Poultry feed mill machines are selected based on total plant output, such as 5 T/H, 10 T/H, or higher continuous production.

2

Process Flow Configuration: A complete poultry feed production line usually includes grinding, mixing, pelleting, cooling, screening, and packing sections.

3

Automation Level Requirement: Decide whether you need semi-automatic or fully automatic feed mill machines based on labor cost and management level.

4

Long-Term Production Stability: When choosing a poultry feed mill machine, focus on durability, continuous operation capability, and maintenance convenience.

5

Choose a Reliable Supplier: A reliable supplier should offer complete solutions, not just individual machines. Good after-sales service and technical support ensure stable long-term operation of the feed mill.

Advantages of RICHI Poultry Feed Mill Machine

The RICHI poultry feed mill machine combines advanced technology, high-quality materials, and user-friendly design to deliver reliable and efficient feed production. With superior pellet consistency, low energy consumption, and broad raw material adaptability, our machines are ideal for poultry farms and commercial feed mills seeking stable operation, reduced maintenance, and cost-effective feed production.

Advanced Pelletizing Technology

Utilizes precise pressure and temperature control to produce dense, uniform pellets that enhance feed efficiency and reduce waste.

Wide Raw Material Compatibility

Handles corn, soybean meal, wheat bran, fish meal, and other additives, allowing flexible feed formulations.

Stable Operation with Low Energy Consumption

Optimized design reduces vibration and energy usage while maintaining high output efficiency.

Uniform and Durable Pellets

Produces dense pellets with consistent size, reducing feed waste and improving digestibility.

Modular Design for Easy Maintenance

Modular components allow quick assembly, disassembly, and replacement, simplifying routine maintenance and reducing downtime.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 140 countries and regions worldwide. Our poultry feed mill machines are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

Tailored feed processing machinery to meet your specific needs.

Modern Workshop

State-of-the-art manufacturing facilities ensure precision, durability, and consistent quality.

On-site Installation

Professional engineers provide installation services on-site for smooth start-up.

Information Sharing

Keep clients updated with technical knowledge, process improvements, and industry trends.

On-the-spot Training

Hands-on training ensures your staff can operate and maintain equipment efficiently.

After-Sales Service

Timely support and maintenance services to minimize downtime and maximize production efficiency.

Frequently Asked Questions About Poultry Feed Mill Machine

Does a poultry feed mill machine support different poultry species such as broilers, layers, ducks, and quails?

+

Yes. A poultry feed mill machine is designed to be highly versatile rather than limited to a single feed type. By adjusting feed formulations, pellet diameters, and processing parameters, the machine can produce a wide range of poultry feeds, including broiler starter, grower and finisher feed, layer feed, breeder feed, as well as duck and quail feed.

This flexibility allows one production line to meet the nutritional requirements of different poultry species and growth stages, making it suitable for diversified poultry farms and commercial feed mills supplying multiple markets.

Could you provide some poultry feed formulations?

+

Yes. Below are several reference poultry feed formulations for different poultry types and growth stages. These formulas are for general guidance only and can be adjusted according to local raw material availability, feed standards, and nutritional targets.

- Broiler Starter Feed (0–3 weeks): Corn 50%-55%, Soybean meal 30–35%, Fish meal 5–7%, Wheat bran 3–5%, Vegetable oil 2–3%, Dicalcium phosphate + limestone 2–3%, Premix (vitamins & minerals) 1%

- Broiler Grower Finisher Feed (4–6 weeks): Corn 55–60%, Soybean meal 25–30%, Wheat bran 5–8%, Fish meal 3–5%, Vegetable oil 2–3%, Mineral additives + premix 2–3%

- Layer Feed (Laying Period): Corn: 50–55%, Soybean meal: 18–22%, Wheat bran: 5–8%, Limestone (calcium source): 8–10%, Dicalcium phosphate: 1–2%, Premix (vitamins & minerals): 1%

- Duck Feed (Grower Stage): Corn: 45–50%, Rice bran: 10–15%, Soybean meal: 20–25%, Fish meal: 5–7%, Wheat bran: 5–8%, Premix + mineral additives: 2–3%

How much does it cost to invest in a 5T/H poultry feed mill machine?

+

In general, the standalone poultry feed pellet mill price with a capacity of around 5 tons per hour ranges from USD 25,000 to 32,000, depending on the machine model, configuration, and technical specifications.

If your project requires not only the pellet mill but also a complete poultry feed production line (including crushing, mixing, cooling, conveying, electrical control, and optional packaging systems) the total investment will be higher. In this case, the overall project cost typically falls within the range of USD 70,000 to 250,000, depending on the production capacity, automation level, and customized requirements.

Can a poultry feed pellet mill project for chicken be scaled up in the future?

+

Yes. A chicken feed manufacturing plant can be scaled up in the future if it is properly planned from the beginning. Most modern poultry feed pellet mills are designed with modular and expandable structures, allowing additional equipment or higher-capacity machines to be added as production demand increases.

In practice, scale-up options may include upgrading to a larger pellet mill model, adding parallel pelletizing lines, increasing raw material handling and mixing capacity, or integrating automated conveying and packaging systems. With sufficient space reserved in the plant layout and compatible electrical and control systems, a small or medium poultry pellet mill can be smoothly expanded into a higher-capacity commercial feed production facility.

How much does the poultry feed mill machine cost?

+

The cost of the system depends on its production capacity, automation level, and optional features. Generally, a complete poultry feed production line ranges from $10,000 to $2,800,000 USD, covering small to large commercial poultry feed operations. Your investment should be based on your production requirements, feed types, and future expansion plans.