Rabbit Pellet Making Machine

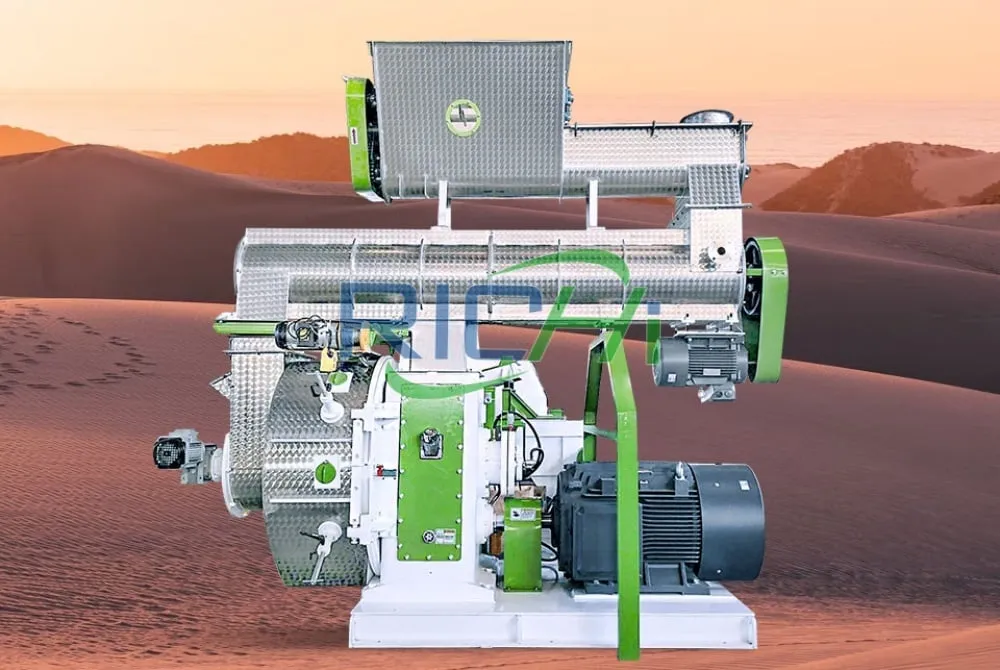

RICHI rabbit pellet making machine is a feed processing machine specifically designed for rabbit farming.

General Production for Rabbit Pellet Making Machine

RICHI rabbit pellet making machine is a feed processing machine specifically designed for rabbit farming.

RICHI Rabbit Pellet Making Machine For Sale

With the development of the rabbit farming industry, breeding models are transforming from traditional small-scale operations to large-scale and standardized production. As a important component of farming operations, feed quality and feeding efficiency have become key factors of breeding profitability. Rabbits have a unique physiological structure and feeding habits. They prefer pellet feed and demand high standards for feed freshness and nutritional balance. Thus, the form and quality of feed are important.

As the key equipment for converting powdered feed into pellet feed, it employs scientific mechanical processing techniques. After blending multiple raw materials in precise proportions, such as corn, soybean meal, bran, alfalfa meal powder and etc., it becomes uniform-sized pellets with optimal hardness through extrusion and conditioning processes. These pellets have uniform size and optimal density, which is suitable for rabbits’ feeding habits. This design effectively prevents selective eating for improving feed utilization and reduces feed loss during storage and transportation.

RICHI rabbit pellet machine can produce not only for rabbits but also for various animals such as chickens, ducks, pigs, cattle, and sheep.

RICHI MACHINERY

Core Components Display

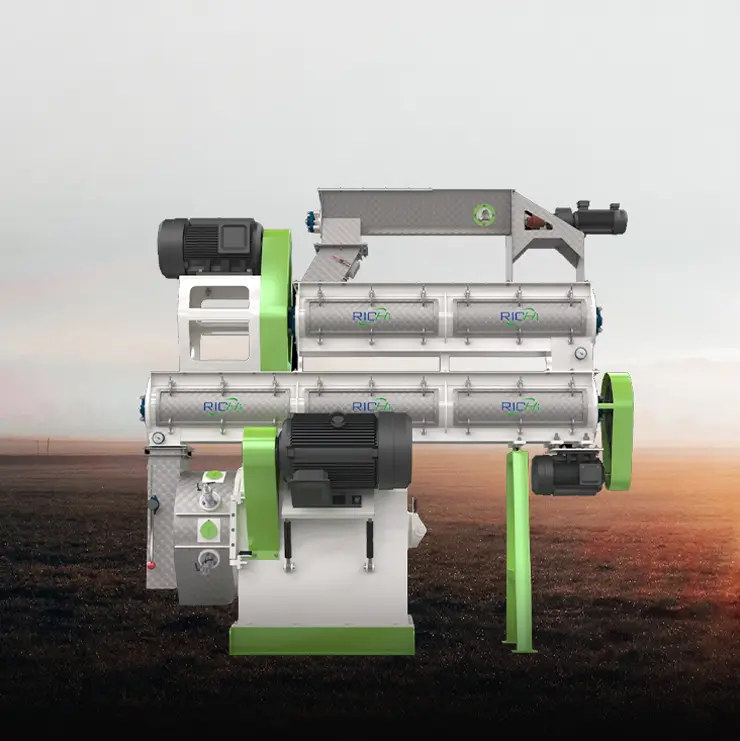

The excellent performance of RICHI SZLH Series Rabbit Pellet Making Machines derives from the delicate polishing and precise control of every core component.

Working Video

The rabbit pellet making machine is a ring die pellet machine with high output and low energy consumption.

The rabbit pellet making machine is mainly suitable for processing various animal feed pellets in large feed mills, which has stable performance and long service life.

In addition to producing rabbit feed, it can also process various feeds for chickens, ducks, cattle, and other animals with exceptional versatility. Because of the robust construction and the use of wear-resistant materials for key components, the machine operates with remarkable stability, which is less prone to malfunctions, and it boasts a long service life, which makes it the first choice for many professional feed production enterprises.

Rabbit Pellet Making Machine Working Principle

The production process of rabbit pellet making machine can be divided into four key steps. Each step directly impacts the quality and yield of the final product.

Feeding

We need to add the mixing powder according to the rabbit feed formula into the hopper. Under the force of gravity and the screw conveyor, the powder enters the pelleting chamber. The rabbit feed pellet mill employs intelligent control to automatically adjust the feeding rate, which ensures that the feed powder is mixed in the correct proportions.

Conditioning

The add of steam not only makes the raw materials easier to form but also activates their nutritional components, which improves the digestibility and absorption rate of rabbit feed. At the same time, it effectively kills harmful microorganisms, which makes the rabbit feed more nutritious. The optimal conditions for rabbit feed pelleting are a moisture content of 16%-18% and a temperature of 75°C-85°C.

Pelleting

The raw materials after tempering are sent into the most important pelletizing chamber. The core components are the ring die and the press rollers inside it. Under the squeeze of the rollers and ring die, the raw materials are compressed and forced through the small holes in the ring die, which forms high-density feed pellets.

Cutting

The pellet feed is cut into the desired length by the cutting blades mounted on the outer side of the ring die. By adjusting the position and rotational speed of the cutting blades, the length of each feed pellet can be precisely controlled. This ensures that all produced pellets are uniformly sized and neatly shaped, which is convenient for packaging, transportation, and rabbit consumption.

Rabbit Pellet Making Machine Parameter and Price

RICHI offers a range of feed pellet machine models to meet the needs of farms of all sizes, from family farming operations to large-scale breeding bases.

SZLH250 rabbit pellet making machine

- Capacity: 1-2T/H

- Main motor power: 22kw

- Conditioner power: 1.5kw

- Ring die diameter: 250mm

- Final pellet diameter: 2-12mm

- Price range: 7,000 -10,000$

SZLH320 rabbit pellet making machine

- Capacity: 3-4T/H

- Main motor power: 37kw

- Conditioner power: 2.2kw

- Ring die diameter: 320mm

- Final pellet diameter: 2-12mm

- Price range: 15,000 -20,000$

SZLH350 rabbit pellet making machine

- Capacity: 5-7T/H

- Main motor power: 55kw

- Conditioner power: 3kw

- Ring die diameter: 350mm

- Final pellet diameter: 2-12mm

- Price range: 20,000 -30,000$

SZLH420 rabbit pellet making machine

- Capacity: 8-12T/H

- Main motor power: 110kw

- Conditioner power: 7.5kw

- Ring die diameter: 420mm

- Final pellet diameter: 2-12mm

- Price range: 30,000 -40,000$

SZLH508 rabbit feed pellet machine

- Capacity: 10-18T/H

- Main motor power: 160kw

- Conditioner power: 11kw

- Ring die diameter: 508mm

- Final pellet diameter: 2-12mm

- Price range: 40,000 -60,000$

SZLH558 rabbit feed pellet machine

- Capacity: 15-25T/H

- Main motor power: 180kw /220kw

- Conditioner power: 11kw

- Ring die diameter: 558mm

- Final pellet diameter: 2-12mm

- Price range: 60,000 -70,000$

SZLH678 rabbit pellet making machine

- Capacity: 20-30T/H

- Main motor power: 220kw /250kw

- Conditioner power: 11kw

- Ring die diameter: 678mm

- Final pellet diameter: 2-12mm

- Price range: 70,000 -80,000$

SZLH768 rabbit pellet making machine

- Capacity: 25-40 T/H

- Main motor power: 250kw /280kw

- Conditioner power: 11kw

- Ring die diameter: 768mm

- Final pellet diameter: 2-12mm

- Price range: 80,000 -90,000$

SZLH858 rabbit pellet making machine

- Capacity: 28-45 T/H

- Main motor power: 315kw /355kw

- Conditioner power: 15kw

- Ring die diameter: 858mm

- Final pellet diameter: 2-12mm

- Price range: 90,000 -100,000$

How to Select the Right Rabbit Pellet Making Machine?

We should avoid blindly pursuing low prices or high output. What best suits our own needs is the optimal solution.

1.Determining Farm Scale

Required rabbit feed production is based on farm scale.

Small-scale family farms (50-200 rabbits): Select small pellet mills with hourly capacities of 100-500 kg (e.g., flat die pellet machines). These have simple structures, compact footprints, and they are suitable for batch production.

Medium-sized farms (200-1000 rabbits): The medium-sized ring die pellet making machine with an hourly output of 500-1500 kg provides a balance between production capacity and stability, which allows for continuous daily production.

Large-scale rabbit farms (1,000 rabbits or more): Large-scale ring die pellet making machine with an hourly output of 1,500 kilograms or more are required, which are equipped with automatic feeding, cooling, and screening systems to achieve automated production lines and reduce labor costs.

2.Determining the Feed Formula

Select the machine model based on the feed formulation. We can also provide some formulas for your reference if you are unsure about the feed formula.

High crude fiber content (e.g., alfalfa hay, straw exceeding 30%): It is recommended to prioritize ring die rabbit pellet making machine. Due to the strong compression force between the rollers and the die, they can effectively address the challenge of forming coarse-fiber raw materials.

When adding liquid ingredients (such as oils, molasses): It is recommended to select models equipped with a tempering unit. This allows the ingredients to be thoroughly mixed and softened via a steam device, which avoids loose particles.

High-quality feed ingredients (with high proportions of soybean meal and corn): Flat die pellet mills can meet requirements at lower costs, which are suitable for small-scale users.

3.Selecting Mold Specifications

Specify pellet specifications to match mold parameters.

The diameter of rabbit feed pellets must match the growth stage: 1.5-2mm for young rabbits, 2-3mm for juvenile rabbits, and 3-4mm for breeding rabbits. Additionally, the ratio of mold length to hole diameter directly affects pellet hardness. The recommended feed compression ratio for rabbits is 8:1–12:1, because higher ratios produce harder pellets.

4.Comparing Equipment Manufacturers

Stable, durable, and easy-to-maintain equipment is the key.

We should prioritize manufacturers specializing in rabbit pellet making machine and confirm the availability of after-sales support. For example, services should include free installation and commissioning, guidance on die replacement, and on-site troubleshooting.

Advantages of rabbit pellet making machine

RICHI rabbit pellet making machine is specifically designed for the physiological characteristics of rabbits, which enables efficient pellet production and stable output for both small-scale and large-scale farming operations.

High Output And Low Energy Consumption

Highly automated

With automatic feeding, tempering, and pelletizing integrated into one system, operation is simple and requires no specialized technicians, which is suitable for livestock personnel to master quickly.

High pellet formation rate

This rabbit pellet making machine utilizes specialized 2-4mm dies, which is suitable for rabbit consumption. Additionally, pellet hardness and length can be controlled by adjusting parameters such as temperature and pressure, in order to accommodate the feeding requirements of rabbits at different growth stages.

Safety

The rabbit feed pellet making machine’s main door cover is equipped with a limit switch. When the door is opened, the main motor automatically shuts off, which achieves proactive protection.

High Efficiency

The main drive system employs gear transmission for high efficiency, which increases output by 15% compared to belt-driven models. It ensures smooth gear operation and low noise levels.

Long service life

The main transmission housing is cast for high load capacity and excellent stability. The feed auger, conditioner, and main door cover are constructed from stainless steel to prevent equipment corrosion from contaminating raw materials.

Durable and Reliable

It is made entirely of high-strength alloy steel, and the key components are specially processed, which ensures a service life of over 10 years.

Cases For Rabbit Pellet Making Machines

RICHI rabbit pellet making machines have gained recognition from customers worldwide.

1-2T/H Rabbit Pellet Making Machines in Nigeria

Date: 2024

Background: A family farm in the Nigeria primarily raises meat rabbits and Angora rabbits, with a population of approximately 500. In the past, they purchased commercial rabbit feed, but in recent years they have sought to better control feed costs and flexibly adjust formulations according to different growth stages of the rabbits.

15-20T/H Rabbit Pellet Making Machines in Spanish

Date: 2024

Background: An agricultural cooperative comprising over 10 specialized rabbit farms, with an annual output exceeding 200,000 meat rabbits. The cooperative operates a centralized large-scale feed processing plant that uniformly supplies feed to all members.

5-6T/H Rabbit Pellet Making Machines in America

Date: 2025

Background: This company specializes in premium pet rabbit food. Their target customers are owners who prioritize pet health, and they demand feed made from organic, natural, additive-free ingredients that deliver targeted benefits such as digestive support and coat enhancement.

3-4T/H Rabbit Pellet Making Machines in French

Date: 2024

Background: This is a family farm specializing in pet rabbit breeding. It has long time for purchasing commercial rabbit feed from feed mills. Moreover, commercial feed uses a common formula that cannot be adjusted according to the rabbits’ different growth stages.

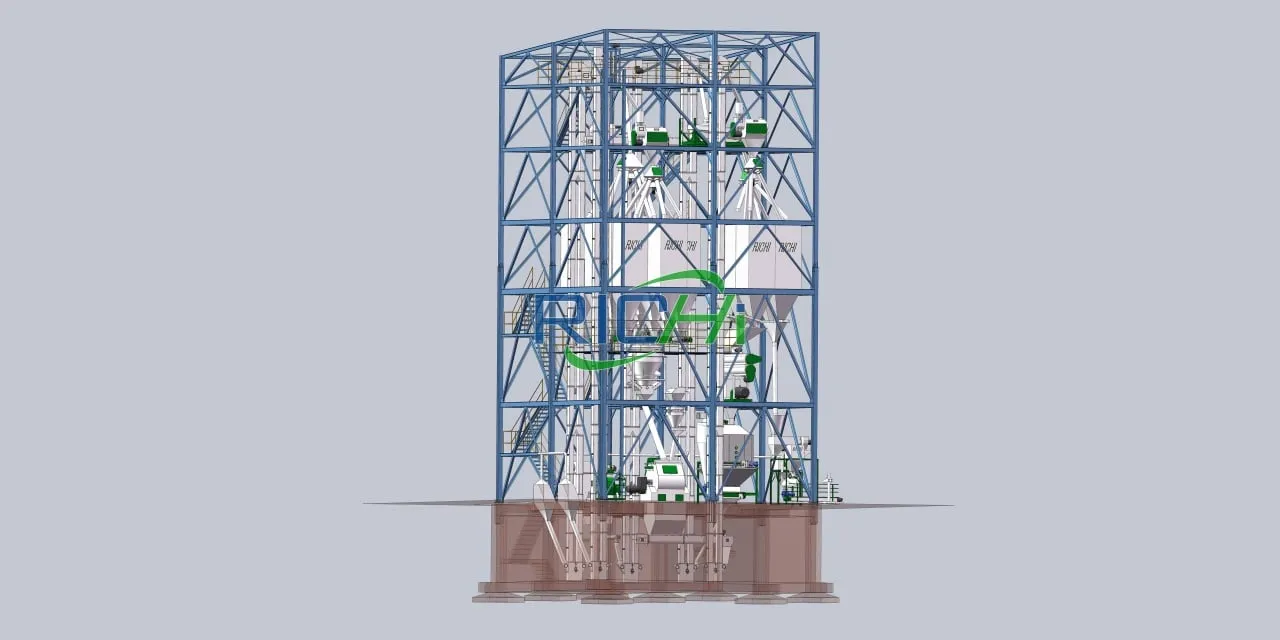

Rabbit Pellet Production Line

RICHI rabbit pellet making machine’s capacity ranges from 1-40T/H, which can be used for rabbit feed pellet production lines with capacities of 0.7-100T/H. Below is the process flow for rabbit feed pellet production lines.

1.Crushing- Water-drop Hammer Mill

First of all, it is necessary to crush the food materials which are prepared according to the formula. This not only can ensure the pelleting effect of the feed pellet press, but also can make the raw materials easier to digest and absorb by the animals.

2.Mixing-Paddle Mixer

After crushing, we need a feed mixer to mix the crushed raw materials evenly. It can make the made feed pellets nutritionally balanced, and promote the healthy growth of animals.

3. Pelleting–Animal Feed Mill Equipment

Pelleting machine is the key equipment of the feed production line, which directly determines the output of the production line and the quality of the pellets. Therefore, the equipment selection and operation of this step must be emphasized.

4. Cooling-Counter Flow Cooler

The just-made feed pellets temperature and humidity are very high, can not be immediately bagged, easy to cause pellets cracked. Therefore, it is necessary to utilize the cooling machine to cool the feed pellets to room temperature before packing.

5.Sifting-Powder Cleaning Machine

After cooling, the mixed material is screened to remove clumps, which ensures the quality of the compound feed.

6. Packing-Automatic Packing System

Customers can choose packing method according to their needs. Most customers choose to use automatic packing machine to pack the feed pellets in bags.

FAQ About Rabbit Pellet Making Machine

What are the requirements for raw materials before pelleting?

+

In summary, there are three key requirements:

- Pellet size: Raw materials must be ground fine enough to pass through a 1.2mm screen. Coarse powder may cause forming difficulties, brittle pellets, and mold wear.

- Moisture Content: The ideal moisture range for raw materials is 15%-18%. Too low moisture makes pellet formation difficult and reduces output. Too high moisture results in soft pellets that easily block the die.

- Formulation: Raw materials must contain a certain proportion of starch and protein to provide binding properties when heated. Pure grass powder is difficult to form and typically requires adding at least 10%-20% of binding materials.

How do I adjust the moisture content of the raw materials?

+

The best method is to lightly spray water and mix thoroughly. You can sprinkle water with a sprayer while stirring the powder. The ideal state is when the materials form clumps that break apart easily upon light touch. Do not pour water directly, because it will cause clumping and uneven distribution.

What international certifications do you hold?

+

We possess a series of internationally recognized certifications, including European CE certification, German TÜV certification, and ISO 9001 quality management system certification.

- CE Certification: A mandatory passport for products entering the EU market, ensuring our equipment complies with EU safety, health, and environmental standards.

- TÜV Certification: A global symbol of high quality and safety, representing rigorous testing by the German Technical Inspection Association.

- ISO 9001: Ensuring our production and management processes adhere to an international quality assurance system.

These certifications are your guarantee of confidence, which means our products meet international standards and can help you clear customs smoothly and use them safely.

How can I trust the quality of your products?

+

We can provide:

- Factory tours: Welcome to visit our modern production facilities and witness the manufacturing process.

- Virtual factory inspections: If visit is inconvenient, we can conduct a live video to give you a virtual visit of our factory.

- Test run videos: Before placing an order, we can conduct free test runs with your specified materials and record high-definition videos to demonstrate the results.

- Customer case studies: We can share successful case studies from clients with similar requirements for your reference.

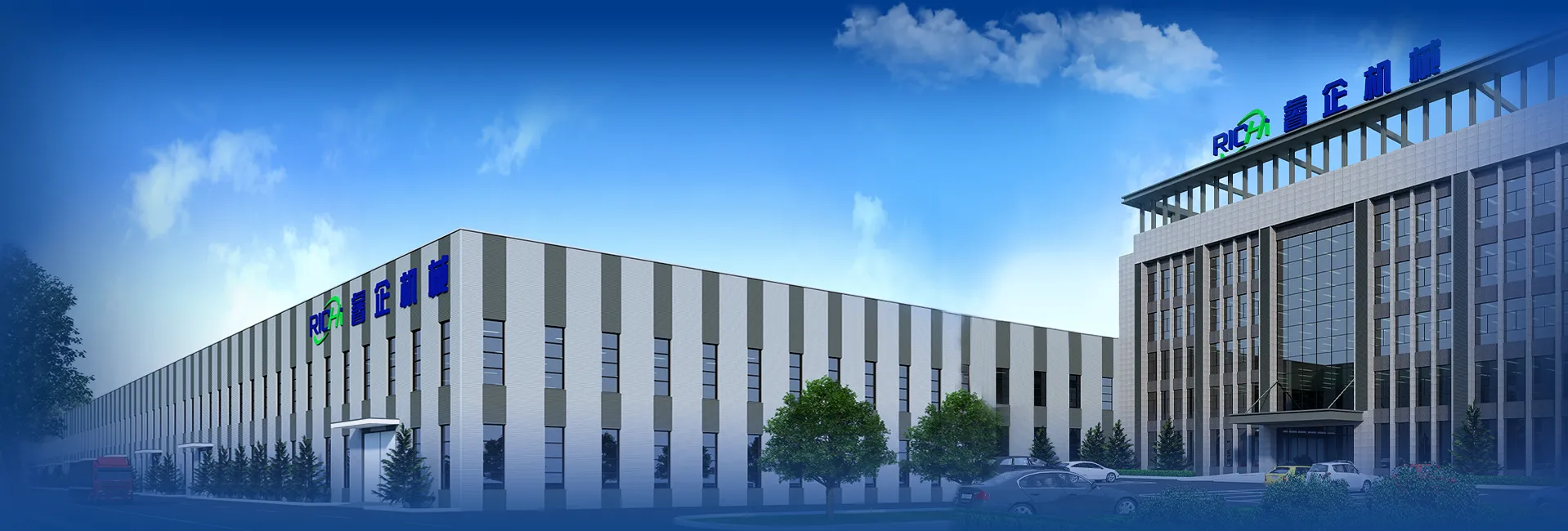

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.