Sawdust Pellet Machine Price

RICHI MACHINERY

Factors Affecting Sawdust Pellet Machine Price

This industrial-grade pelletizer is available in multiple models and capacities to accommodate sawdust pellet production at various scales. A single pelletizer has a production capacity ranging from 0.5 to 8 T/H. We also offer customized equipment to meet your specific production requirements.

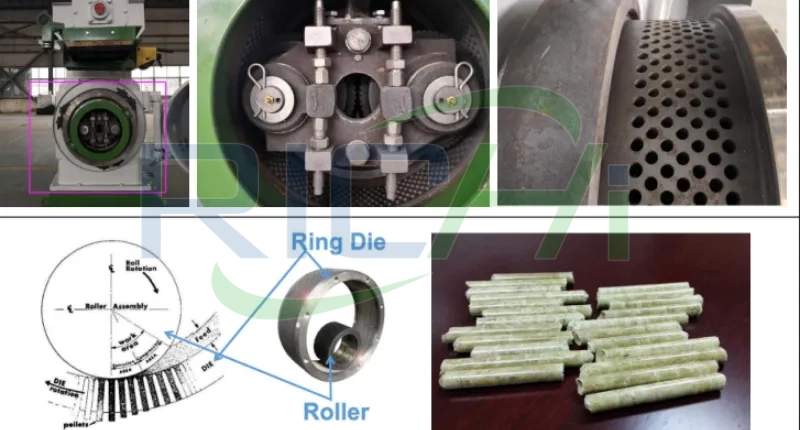

To accommodate diverse raw material conditions, we have designed multiple ring die models. By installing different ring dies, the machine can handle pelletizing requirements for single or mixed raw materials. This enables the production of pellets in a wider range of types and sizes.

Additionally, the sawdust pellet mill price is influenced by the level of automation. Our advanced manufacturing facility offers a range of highly automated pelletizing solutions.

Different Models of Sawdust Pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Breaker Feeder Power(kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter(mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Pellet Diameter(mm) | 4-12 | |||||

| Capacity(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

| Price (USD) | 15100 $ | 20500 $ | 29600 $ | 45100 $ | 67100 $ | 80500 $ |

The table above provides a reference for sawdust pellet machine price and production capacities. These are suitable for production lines operating at capacities ranging from 0.5 to 40 T/H. Among these, sawdust pelletizers for 4-8 T/H capacities are typically customized solutions. We can also provide exclusive bespoke designs based on your specific requirements.

Advantages of Sawdust Pellet machine for sale

- Reduce energy consumption per unit by 20%

- Increase output per unit by 15%

- Variable-frequency impeller feeder, forced feeder, for smooth feeding

- Dual pressure roller design to enhance forming efficiency

- Innovative ring die aperture improves unit output and forming quality

- Siemens 8-level motor, for stable operation

- High-precision gear transmission, SKF bearings, extend service life

- Wear parts made from harder, wear-resistant alloy 42 CrMo

- Pellet length can reach 4-5 times the diameter.

- Oil-injection observation port for precise lubrication control.

In addition to the innovative structural advantages mentioned above, our pellet mills also feature simple operation and easy maintenance. For large-sized ring dies, we can provide a manual lifting device to make replacement easier. Regarding sawdust pellet machine price, we offer equally competitive rates.

Display of Different Sawdust Pellet mill

The sawdust pellet machine price depends on the model. Below are different pellet machines for your selection. Each model offers high efficiency and energy savings. They can be used to produce pellets from various wood materials, ensuring high utilization and high returns.

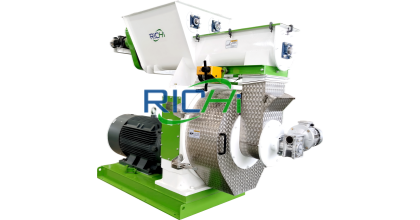

MZLH320 samll sawdust pellet machine

It is suitable for sawdust pellet production with a small capacity of 500-600 kg/h, which facilitates flexible production.

MZLH350 sawdust pellet mill for sale

This equipment is capable of efficient sawdust pelletization at a capacity of 1-1.2 T/H, suitable for small to medium-scale production.

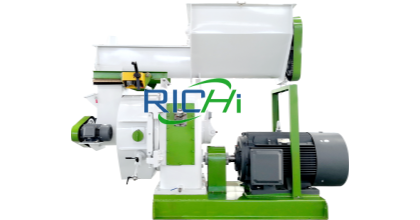

MZLH420 sawdust pellet making machine

It does not require high precision in material fineness and can pelletize more complex irregular materials.

MZLH520 sawdust pellet press

With a production capacity of 2.8–3.0 T/H, this pelletizer offers efficient pelletization and a high return on investment.

MZLH678 sawdust wood pellet machine

This model is primarily a customizable option, with a stable structure capable of executing complex pelleting tasks for extended periods.

MZLH768 automatic sawdust pelletizer

The fully customizable large pelletizer adapts to wood pellet production with diverse raw materials and varying requirements.

In addition to the above, we can also provide highly automated production line solutions for large-scale production facilities, such as sawdust pellet plants and biomass pellet manufacturers. The sawdust pellet machine cost within these solutions depends on your chosen levels of automation and scale.

complete sawdust pellet production line for sale

This wood pellet production line solution has a capacity range of 0.5–40 T/H. To meet a variety of production needs, we offer fully automated production lines as well as disconnect lines. The fully automated sawdust pellet machine price is higher than other options. We will provide the most optimal production solution tailored to your needs.

RICHI Machinery also offer turnkey services, including project planning, on-site construction, wood pellet manufacturing equipment installation and training. Please feel free to contact us for a complimentary consultation.

Various kinds of sawdust pellet production line

small-scale sawdust wood pellet production line in indonesia

Capacity:

1-1.2 T/H

Pellet Diameter:

6 mm

automatic sawdust pellet making plant in thailand

Capacity:

5-6 T/H

Pellet Diameter:

8 mm

biomass sawdust pellet manufacturing plant in USA

Capacity:

10-11 T/H

Pellet Diameter:

8 mm

Frequently Asked Questions

We understand your concerns when investing in a sawdust pellet making machine. Regarding sawdust pellet machine cost, we have compiled answers to the following common questions, which should help you to make an informed decision. If you have any further questions, please feel free to contact us anytime.

–

Which factors influence a sawdust pellet machine price?

There are four primary factors: production capacity, motor power, automation level, and raw material characteristics. For large-scale pellet production, pelletizers with higher capacity and automation levels command a premium over basic models.

Complex raw materials place higher demands on the pelletizing system, which also affects the machine’s price. However, a fully equipped configuration can significantly boost production efficiency, ensure long-term suitability, and deliver more favourable investment returns.

–

Does machine model significantly impact sawdust pellet machine price?

Pelletizers for different production scales exhibit noticeable price variations. Generally, small-scale pelletizers with a production capacity of 0.5-1.2 t/h are ideal for low-capacity production. They are ideal for customers requiring modest output and for handling easily processed raw materials.

Large-scale pelletizers typically feature higher power ratings and advanced automation, with less stringent requirements for raw material fineness. Consequently, they offer greater convenience and efficiency, though at a higher price point. Industrial-grade pelletizers are designed for sustained, large-scale production, delivering superior cost-effectiveness.

We also offer other high-value biomass pellets making machine for sale. These include straw pellet mill, alfalfa pellet mill for sale, hay pellet machine for sale, cow manure fertilizer pellet machine, organic fertilizer pellet machine, EFB pellet machine, and more.

–

Does this sawdust pelletizer price include installation and other fees?

The price of our pelletizer is solely for the machine itself and does not include any additional service charges. Each unit undergoes pre-shipment testing to ensure optimal performance. We also provide a user manual and video tutorials.

For production line solutions, we provide on-site installation, commissioning and training services. Long-term online technical support and other after-sales services are also available. We recommend consulting the manufacturer before purchasing equipment to clarify service items and avoid unexpected costs.

–

Does the level of automation directly affect the sawdust pellet mill price?

Yes. Generally, the price of sawdust wood pellet press machine increases with their automation level. This primarily applies to production line configurations. We offer two automation solutions: fully automated and semi-automated production lines.

For sawdust pellet plants and biomass pellet manufacturers, we recommend selecting a fully automated sawdust pellet production line. High automation levels significantly reduce labor costs and enhance production efficiency. Over the long term, this approach delivers a higher return on investment.

–

What is the difference between the price of a sawdust pelletizer and a complete production line?

Beyond the pelletizer, most sawdust pellet production lines also include key segments such as crushing, drying, cooling, screening, and packaging. Therefore, their price is significantly higher than that of a single pelletizer.

Complete production line solutions are better suited to large-scale sawdust pellet production. For example, manufacturers with abundant raw material supplies such as wood pellet plants, biomass pellet plants, and wood processing factories.