Shrimp Feed Plant

A shrimp feed plant refers to an automated production system that processes various raw materials such as fish meal, soybean meal, wheat flour, vitamins, and minerals through a series of specific manufacturing processes. This system transforms these ingredients into pellet feed that meets the nutritional requirements of shrimp and exhibits high stability in aquatic environments.

Shrimp Feed Plant

The advantage of the RICHI shrimp feed plant is that it provides precise control over the sinking and floating properties of shrimp feed. Because shrimp feed is a sinking feed, it must maintain stability in the water for as long as possible after feeding to prevent waste and water pollution. This places extremely high demands on the feed’s particle density and water resistance. Next, shrimp exhibit unique feeding habits. They typically use their claws to capture particles, which requires shrimp feed pellets to be uniformly sized, well shaped, and smooth without dust. This facilitates feeding and reduces wear on the digestive tract. These seemingly simple characteristics are actually based on extremely precise parameter control during the production line’s tempering, pelleting, conditioning, and drying processes.

The design and operational quality of this production line directly determine the final quality of shrimp feed, which in turn impacts shrimp growth rates, health conditions, and the economic benefits for farmers. Therefore, selecting an appropriate shrimp feed plant is of important in aquaculture. It must produce feed that meets the nutritional requirements of shrimp at different growth stages, maximizes growth potential, and ensures the health of the shrimp population.

Modern shrimp feed production lines are developing toward intelligent, energy-efficient, and environmentally friendly directions. By employing automation technology, they achieve precise control over parameters of the whole production process, so as to produce higher-quality, more efficient, and safer shrimp feed consistently. This provides a solid foundation for the development of modern aquaculture.

Full Process Video of Shrimp Feed Plant

SHRIMP PELLET

Welcome to view our shrimp feed plant in operation. This modern production line that integrates nutrition science and automated control is the foundation for ensuring healthy shrimp farming. Water stability, nutrient absorption rate, and population uniformity are the key indicators that directly determine the success or failure of aquaculture. A complete modern shrimp feed plant is a complex system project, which contains a full set of equipment from raw material reception to finished product packaging. Its core objective is to efficiently produce high quality feed that meets the nutritional requirements of shrimp and exhibits excellent stability in water.

+86 15038392800

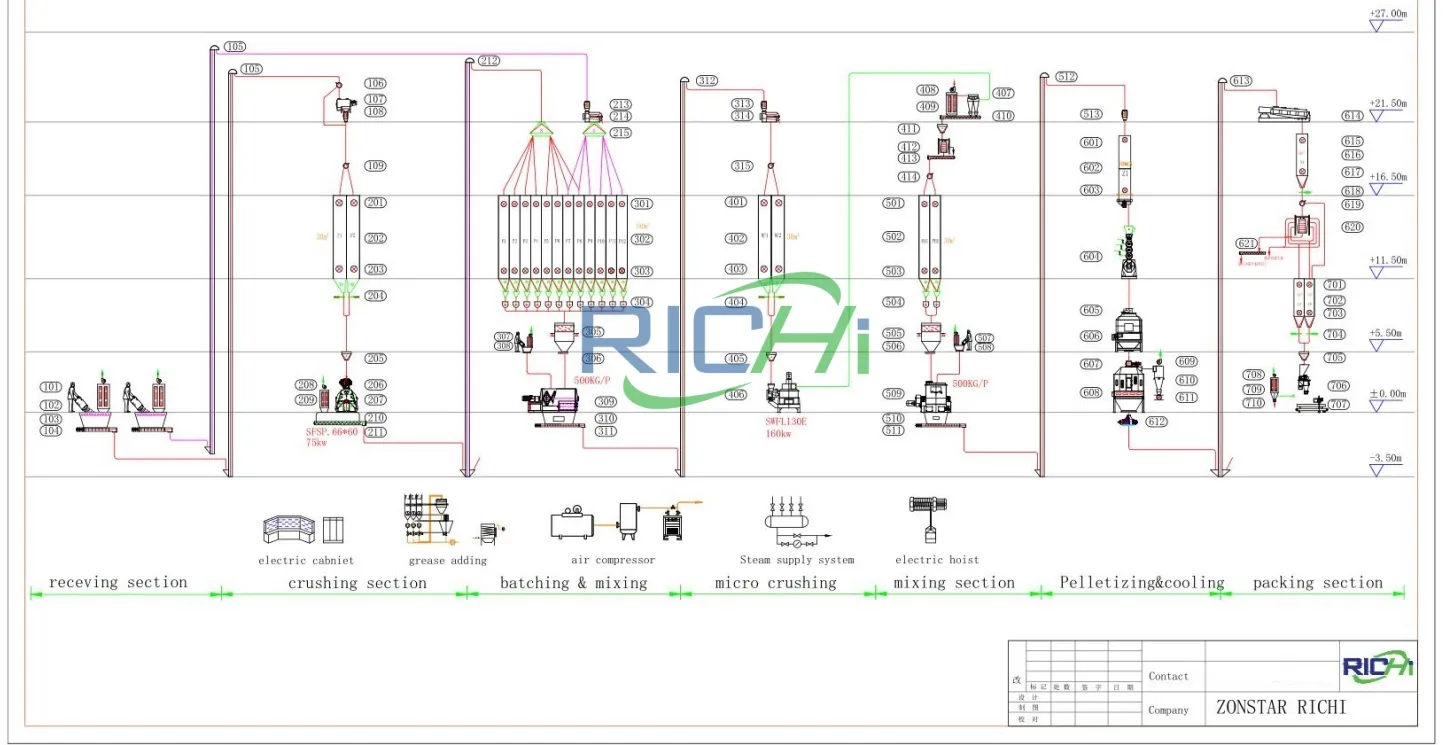

Production Process of Shrimp Feed Plant

A shrimp feed plant refers to a complete set of mechanical equipment that processes various raw materials such as fish meal, soybean meal, wheat flour, vitamins, and minerals through a series of continuous operations like crushing, mixing, tempering, pelleting, cooling, and screening to produce standardized pellet feed. There are many kinds of shrimp feed plant, which have different production processes, output capacities, and configurations. Next, I will explain the process of shrimp feed plant with an output capacity of 2-2.5 tons per hour as an example.

1

Cleaning

This stage receives various raw materials, and removes impurities such as stones and hemp ropes, as well as metallic foreign objects like nails in order to protect the safety of subsequent crushing and pelleting equipment.

2

Crushing

The crusher will crush the raw materials into extremely fine powder, which is a crucial step in producing high quality shrimp feed. The finer the powder, the higher the stability of the shrimp feed in water.

3

Mixing

According to scientific feed formulations, various raw materials and additives such as vitamins and minerals are uniformly blended together to ensure consistent nutritional content in every feed pellet.

4

Pelleting System

This system compresses powdered materials into pellets of specific shapes and sizes. The shrimp feed mill is the core equipment in shrimp feed plant, which directly determines both production output and pellet quality.

5

Oil Spraying

The surface of cooled pellets is uniformly sprayed with oil or other liquid additives. This forms a protective film on the pellet surface, which further enhances stability in water while also increasing the feed’s energy content.

6

Cooling System

The pellets from the shrimp feed mill are hot and contain high moisture content. They must undergo drying and cooling to reduce moisture to 12% for proper storage and transportation, so as to prevent feed spoilage.

7

Screening System

This system separates fine powder and oversized particles from the finished product to ensure uniform particle size. The fine powder return to the production line for re-granulation.

8

Packaging System

Qualified finished products are weighed and sealed into packaging bags. The sealing method can be thermoplastic sealing, seam sealing, or mixed sealing.

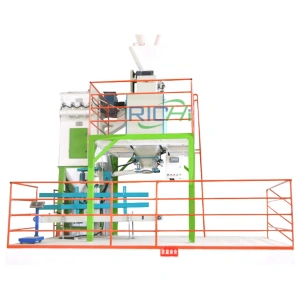

Main Shrimp Feed Plant Equipment

Next, let’s take a look at the main equipment of the RICHI shrimp feed pellet production line. Each piece of equipment that we design is made of premium materials, such as stainless steel construction, Siemens motors, and SKF bearings. The excellent allocation and perfect coordination of these devices ensure the efficient and stable operation of the shrimp feed plant.

Primary cleaning screen

It is mainly used to remove large impurities such as hemp ropes, stones, and paper scraps from raw materials.

Magnetic separator

It is used to remove metallic impurities such as nails and screws from raw materials, which protects subsequent crushing and pelleting equipment from damage.

Feed Crusher

The water-drop hammer mill is famous for its high efficiency and uniform particle size. For fish feed, finer raw material particle size is required to enhance feed digestibility and pellet formation quality.

Feed Mixer

Twin-shaft paddle mixers are commonly used, capable of uniformly blending various ingredients in a short time to ensure consistent nutritional content in every feed pellet.

Shrimp Feed Pellet machine

The shrimp feed mill is the core machine in the shrimp feed plant. Its function is to mechanically compress mixed powdered raw materials into pellets of specific shape, density, and size.

Oil Sprayer

Uniform spraying of heat-sensitive liquid nutrients such as fish oil, phospholipids, and vitamin solutions onto the surface of cooled pellets significantly enhances the energy content and palatability of feed.

Cooling Machine

As aquatic feed require high water resistance, cooling should not be too rapid. Therefore, counter-flow coolers are typically used to reduce pellet temperature to near room temperature with ambient air, thereby fixing their structure and preventing mold growth.

Vibrating Screen Classifier

It screens cooled particles, and utilizes the vibrating screen to classify mixtures of different particle sizes, which separates qualified products from powder and oversized particles.

Automatic packaging system

The finished feed is weighed and loaded into packaging bags, and then sealed.

Main Equipment Parameters

Here we introduce the models and specifications of three key pieces of equipment in the shrimp feed plant. We can also customize equipment for shrimp feed plants with different output capacities according to your requirements.

1.Shrimp Feed Pellet Mill

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Capacity(t/h) | 0.2-0.4 | 0.3-1 | 0.5-2 | 1.2-4 | 2-5 | 3-8 | 4-10 | 4.5-12 |

| Main motor power(kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 15 | 1.5 | 1.5 | 2.2 |

| Conditioner power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring die diameter(mm) | 250 | 320 | 350 | 420 | 508 | 558 | 678 | 768 |

| Finished pellet diameter(mm) | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 |

2.Water-drop hammer mill

| Model | SFSP56*40 | SFSP66*60 | SFSP66*80 | SFSP66*100 | SFSP66*120 | SFSP66*150 |

| RotorDiameter(mm) | 560 | 660 | 660 | 660 | 660 | 660 |

| Rotating Speed(r/min) | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 |

| Line speed of hammers(m/s) | 88 | 103 | 103 | 103 | 103 | 103 |

| Power(kw) | 37 | 55/75 | 75/90/110 | 110/132/160 | 160/185/220 | 220 |

3.Feed Mixer

| Model | SLHJ1A | SLHJ1B | SLHJ2A | SLHJ2B | SLHJ3A | SLHJ4A | SLHJ6A |

| Material | Carbon steel | stainless steel | Carbon steel | stainless steel | Carbon steel | Carbon steel | Carbon steel |

| Power (kw) | 11 | 11 | 22 | 22 | 30 | 37 | 55 |

| MixedWeight(kg/batch) | 500 | 500 | 1000 | 1000 | 1500 | 2000 | 3000 |

Advantages of the Shrimp Feed Plant

RICHI shrimp feed mill is specifically designed for the physiological characteristics of shrimp. Therefore, the shrimp feed pellet plant not only enhances feed quality but also provides significant benefits for the aquaculture industry. Below are its key advantages.

Meeting Nutritional Needs

The shrimp feed plant can precisely produce pellets ranging from shrimp fry starter feed (0.15mm) to adult shrimp feed by replacing the die of the shrimp feed mill, which can meet the nutritional requirements throughout the entire life cycle of shrimp and realize precise feeding.

Improving absorption rates

The heat treatment during production denatures proteins and gelatinizes starch, which is more suitable for the digestive physiology of shrimp. This means nutrients in the feed can be absorbed and utilized more efficiently, which directly saves aquaculture costs.

Consult Now >>

High level of automation

The whole process from raw material processing to finished product packaging is fully automated, which only requires 1-2 operators. This significantly reduces labor costs and boosts productivity.

Consult Now >>

Reduction of water pollution

Feed that does not disintegrate means reduced organic pollution in the water, and it is easier to control harmful indicators such as ammonia nitrogen and nitrite. This provides shrimp with a stable, clean growth environment, and fundamentally prevents the occurrence of diseases.

Consult Now >>

Reduction of feed waste

Pellet feed has a compact structure that minimizes waste during feeding, which can reduce feed loss by 20%-30%. It is particularly suitable for feeding aquatic animals.

Balanced Nutrition

Automated batching and mixing systems ensure uniform distribution of micro nutrients such as vitamins and minerals throughout the feed. This eliminates nutritional imbalances and uneven growth sizes in shrimp populations that are caused by inconsistent manual mixing.

Consult Now >>

High stability in water

This is the most important criterion for shrimp feed. The shrimp feed plant employs processes such as grinding and high-temperature tempering to fully gelatinize the starch, which forms a natural binder. This enables the feed pellets to maintain their shape for 2-4 hours in water without disintegrating, which prevents nutrient loss.

Consult Now >>

Efficient Mass Production

A modern production line can operate continuously, with daily output ranging from several tons to hundreds of tons, which enables stable supply to large-scale farms. This is incomparable to any manual or semi-mechanized production.

Consult Now >>

How to Select the Appropriate Shrimp Feed Plant

Selecting the appropriate shrimp feed plant is a critical investment decision that directly impacts product quality, production costs, and the company’s market competitiveness.

1.Determine the Farming Scale: Production capacity is the most direct basis for equipment selection. Determine the annual output based on the farming scale, then decide on the capacity of the machines to purchase.

2.Raw Material Characteristics: The formulation of shrimp feed should specify the raw materials and clearly define their fat, starch, and fiber content, which will impact the selection of grinding, tempering, and pelleting processes.

3.Simple operation, can reduce the labor consumption. The small producion line only needs 12 persons. Even the large ducion ine needs 5-10 persons

4.Key Equipment Configuration

- Crushing System: An ultra-fine crusher must be used. The finer the raw materials are crushed, the better the particle cohesion, the higher the feed’s stability in water, and the greater its digestibility.

- Conditioning System: We should choose a multi-layer conditioner to extend the mixing time between material and steam, so that the starch gelatinizes fully. This is the core step for enhancing water stability.

- Drying and Cooling System: The capacity of dryers and coolers must match the host machine’s production capacity to ensure that particle moisture content is reduced to approximately 12%.

- Automated Control System: We can be equipped with a PLC and touchscreen to enable centralized control and real-time monitoring of critical parameters such as motors, valves, temperature, and weight.

5.Comparing Equipment Manufacturers: We should prioritize manufacturers specializing in shrimp feed mills that offer turnkey solutions encompassing design, equipment manufacturing, installation, commissioning, and training and verify the availability of after-sales support, such as complimentary installation and commissioning, guidance on die replacement, and on-site troubleshooting services.

Client Case Studies

Below are some shrimp feed plant projects we have undertaken. If you are interested in these projects, please contact us for more details.

3-4T/H Shrimp Feed Plant

- Country: Vietnam

- Shrimp Species: Whiteleg Shrimp

- Market Background: The client is a large feed company in Vietnam, primarily serving high-density aquaculture farms in the Mekong Delta region. These farms place extreme importance on feed quality, and require feed that maximizes water stability, promotes rapid and uniform shrimp growth.

- Customer Requirements: The feed must remain intact in water for over 2 hours to minimize water pollution and reduce the burden on filtration systems. The production line must be capable of manufacturing a full range of products, from floating to sinking types, to accommodate farmers’ varying feeding observation habits and aquaculture practices.

2-2.5T/H Shrimp Feed Plant

- Country: Ecuador

- Shrimp Species: Whiteleg Shrimp

- Market Background: The client is a long-established feed company in Ecuador, primarily serving large-scale, low-density pond farming operations in coastal regions. This farming model yields low output but covers vast total areas, which is not easily observable after feeding. Additionally, the client is very sensitive to price.

- Customer Requirements: They need to produce cost-effective sinking feed. They want to minimize production costs while ensuring growth requirements and water stability. The equipment must be able to adapt to the high-temperature, high-humidity coastal environment, with low failure rates and easy maintenance.

1T/H Shrimp Feed Plant

- Country: Indonesia

- Species: Whiteleg shrimp, giant river prawn, etc.

- Market Background: The client is an Indonesia aquatic research laboratory and seedling center that also provides customized feed for small-scale local farmers.

- Customer Requirements: The shrimp feed plant must handle multiple raw material formulations and produce feed pellets ranging from micro-sized particles for shrimp larvae (<0.3mm) to larger pellets for adult shrimp. It must also manufacture nutritionally specialized feeds for different shrimp species.

RICHI MACHINERY

About RICHI

RICHI Machinery was established in 1995 and holds European CE certification, Swiss SGS certification, French BV certification, and ISO 9001 quality management system certification, with a complete international trade system. To better serve our global customers, We have also launched multiple platforms including Alibaba International, Google Ads, Made-in-China.com, and SEO optimization, and own a comprehensive cross-border e-commerce operation system. Up to now, our products have been exported to 108 countries and regions across Europe, the Americas, the Middle East, Asia, Africa, and Southeast Asia, which has earned the trust and recognition of a wide range of customers.

In terms of production, RICHI has a modern production workshop equipped with advanced machinery and technology, which ensures every piece of equipment is manufactured efficiently and with precision. We focus on every production stage, from raw material procurement to finished product shipment after strict quality control to ensure products meet international standards and customer requirements. Our experienced production team can customize equipment according to specific customer needs, so as to meet the usage requirements of different scenarios. Whether it’s small-scale family farming or large-scale enterprise production, we can provide suitable solutions to help customers improve productivity and reduce operating costs.

30+

Years Experience

1000+

Serving customers

140+

Exported countries

2000+

Provided devices

Frequently Asked Questions

If you have any other questions, please email us.

Q1: Can you provide some common shrimp feed formulas?

+

A: Yes, but we need to understand that different shrimp species require different feed formulas, and even the same species requires different formulas at different growth stages. Therefore, we have summarized some common shrimp feed formulas for your reference.

- Juvenile Shrimp Feed Formula: Whitefish meal 35%, soybean meal 20%, shrimp meal 5%, wheat flour 22%, brewer’s yeast 4%, fish oil 3%, soy lecithin 2%, calcium dihydrogen phosphate 1.5%, vitamin premix 1%, mineral premix 1%, attractant 5.5%.

- Medium-aged shrimp feed formula: Common fish meal 25%, soybean meal 25%, peanut meal 8%, corn protein meal 5%, wheat flour 25%, fish oil 2%, soybean oil 1%, soy lecithin 1%, calcium dihydrogen phosphate 1.5%, vitamin premix 1%, mineral premix 1%.

- Homemade Simplified Shrimp Feed Formula: Fresh mixed fish or fish offal 40%, soybean meal or soybean flour 30%, wheat bran or rice bran 20%, sweet potato starch or wheat flour 10%.

Q2: How can I trust the quality of your products?

+

A: We can provide:

- Factory tours: Welcome to visit our modern production facilities and witness the manufacturing process.

- Virtual factory inspections: If visit is inconvenient, we can conduct a live video to give you a virtual visit of our factory.

- Test run videos: Before placing an order, we can conduct free test runs with your specified materials and record high-definition videos to demonstrate the results.

- Customer case studies: We can share successful case studies from clients with similar requirements for your reference.

Q3: How do I adjust the moisture content of the raw materials?

+

The best method is to lightly spray water and mix thoroughly. You can sprinkle water with a sprayer while stirring the powder. The ideal state is when the materials form clumps that break apart easily upon light touch. Do not pour water directly, because it will cause clumping and uneven distribution.