Straw Pellet Mill

A straw pellet mill is a specialized machine designed to convert waste straw into high-density and uniformly shaped pellets, which is a type of biomass energy equipment. Its primary purpose is to address the challenge of straw disposal and transform it into a valuable commodity.

Introduction to Straw Pellet Mill

This machine is not only an eco-friendly device for processing waste but also a tool for enhancing straw value.

Straw pellet mill, professionally known as a biomass ring die pelletizer, is a machine specifically designed to convert agricultural waste into high-density, uniformly shaped cylindrical solid pellets through physical compression.

Straw pellet mills for sale process common agricultural residues such as rice straw, wheat straw, corn stalks, and bean stalks. These materials are inherently bulky, low in density, high in transportation and storage costs, and prone to decay. If burned directly in the field, they also cause severe environmental pollution. The emergence of straw pellet mills can efficiently and massively address this agricultural waste disposal challenge. The final straw pellets represent a new commercial product. The pellets feature uniform particle shape, high density, and strength, which is easy for storage and long-distance transportation. Straw pellets can be used as solid biomass fuel or coarse feed. These pellets serve as a high-quality clean energy source, which can replace coal for heating, industrial boilers, or power generation. They can also function as a staple feed for ruminants, thus achieving the circular utilization of agricultural resources.

Straw Pellet Mill Video

The pellets produced by straw pellet machines serve as both high-quality clean biomass fuel and ideal roughage for ruminants, which really turns waste into treasure and maximizes resource utilization.

Working Principle of Straw Pellet Mills

The working principle of the straw pellet mill involves the physical process of compressing loose straw powder through mechanical pressure, friction-generated heat, and the material’s inherent physical changes. This process forces the material through a specific die, which converts it into high-density pellets. The entire process is divided into four distinct stages.

High Output And Low Energy Consumption

Compression

The crushed straw powder is continuously and evenly fed between the ring die and the press rollers. As the main shaft drives the ring die to rotate at high speed, the immense centrifugal force and the material’s own friction cause the press rollers to rotate in the opposite direction. During this process, the material undergoes dramatically increased compression.

Conditioning

Continuous steam injection generates high temperatures, and intense friction rapidly increases the material’s temperature. This heat softens the lignin in straw, which melts at high temperatures and acts as a natural binder.

Forming

Under immense pressure, the softened and initially bonded material is forcibly extruded through the die holes in the ring die, which forms dense cylindrical strands.

Cutting

Fixed blades installed externally on the ring die cut the continuously extruded straw strips into pellets of a predetermined length.

RICHI MACHINERY

Different Raw Material Conditions

When producing straw pellets, the type, moisture content and shape of the raw material are different. Therefore, a suitable pretreatment process (drying, crushing, mixing, conditioning) must be matched to it in order to produce stable and high-quality pellets with the lowest energy consumption and cost.

Core Components of Straw Pellet Mill

We design each unit with high quality materials, such as stainless steel construction, Siemens motors, and SKF bearings, which ensures the biomass pellets making machine’s high efficiency, stability, and excellent results.

Feeder

Ring Die and Press Rollers

Drive system

Siemens motors

Models and Specifications of Straw Pellet Mills

The straw pellet machine boasts high output and low energy consumption, primarily designed for feed processing plants and biomass fuel plants to produce feed pellets and biomass pellets. Below are the specifications for the CZLH series grass pellet mill. If you’re not sure how to choose, please contact us directly. Additionally, we can customize straw pellet machines according to your requirements.

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power (KW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-breaking Feeder Power (KW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced feeder power (KW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (MM) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished particle diameter (MM) | 4-12 | |||||

| Output (T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4.0-5.0 | 6.0-8.0 |

Why Produce Straw Pellets?

As Clean Biomass Fuel:

- High Energy Density: Loose straw occupies large volumes, resulting in high transportation and storage costs. When compressed into pellets, its energy density significantly increases, close to that of coal, which is more convenient for long-distance transport and centralized storage.

- High combustion efficiency: With low moisture content and uniform shape, pellet fuel achieves more complete combustion in specialized boilers. Compared to direct burning of raw straw, it emits extremely low levels of pollutants, which is a clean energy source.

- Replacing fossil fuels: As a low-carbon renewable energy source, it can effectively substitute coal and natural gas in industrial boilers, power plants, and heating systems, which reduces dependence on fossil fuels.

As Roughage for Ruminants:

- Nutritional Balance: During pelleting, straw can uniformly mix with nutrients such as urea, minerals, vitamins, and soybean meal. Once compressed into pellets, animals cannot selectively feed as they would with loose forage, which ensures that every mouthful provides comprehensive and balanced nutrition.

- Excellent palatability: The high-temperature and high-pressure pelleting process partially breaks down and softens the fiber structure, inducing a gelatinization reaction. This not only enhances palatability but also promotes digestion and absorption in ruminants, thereby improving feed conversion efficiency.

- Reduce waste: Pellet feed offers excellent flowability, which makes it ideal for mechanized automatic feeding systems, thereby significantly reducing waste associated with traditional feeding methods. Additionally, the high density of pellets greatly saves storage space in feed warehouses.

Project Case Studies of Straw Pellet Mills

At present, RICHI straw pellet mills have been exported to over 70 countries worldwide, with the number of projects continuing to grow. As essential equipment for ruminant feed pellet plants and wood pellet manufacturing plants, RICHI straw pellet mill for sale has become the preferred choice for numerous customers.

2 T/H Alfalfa Straw Pellet Mill Project Case Study

- Country: South Africa

- Raw Material: Primarily alfalfa straw, which is the stem portion remaining after alfalfa is harvested and processed into hay bales.

- The project selected a flexible small-scale production line with a capacity of 2 tons per hour, which can be adjusted to produce either feed pellets or bedding pellets based on operational needs.

2.5 T/H Rice Husk and Rice Straw Pellet Mill Project Case Study

- Country: Thailand

- Raw Materials: A mixture of rice husks and rice straw with a blending ratio of approximately 6:4.

- This project is a large-scale commercial operation equipped with multiple pellet production lines. Each unit has an hourly output capacity of 2.5 tons, with a total annual production target exceeding 15,000 tons. It aims to establish itself as a regional biomass fuel supply hub.

5 T/H Wheat Straw Power Generation Fuel Project Case Study

- Country: Poland

- Raw Materials: Primarily wheat straw, blended with a small amount of rapeseed straw and other local agricultural residues.

- The project employs a medium-scale production line featuring one main ring die straw pellet mill with an hourly output of 4-5 tons, which could yield an annual production of approximately 6,000 tons. This capacity is sufficient to meet regional energy demands.

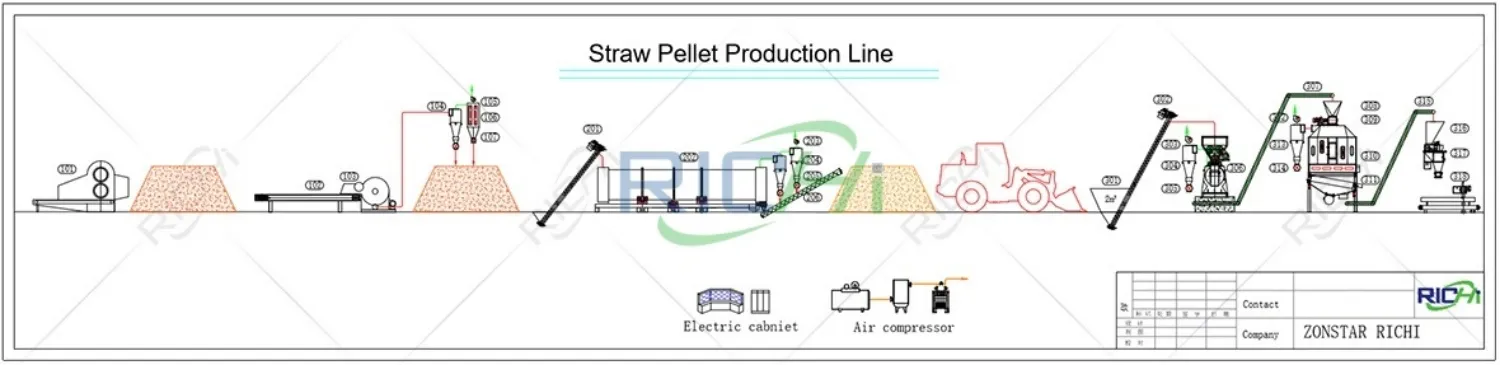

Straw Pellet Production Line

The biomass pellet plant can also be used to manufacture hay pellets, alfalfa pellets, and specialized feed pellets for ruminants, which can meet diverse market demands. Below is a detailed explanation of the core process flow for the straw pellet plant.

1. Raw Material Crushing

A specialized bale-breaking crusher is used to chop long-stemmed straw into 1-3 cm segments. This reduces material volume, prepares it for subsequent fine grinding, and ensures smooth feeding.

2. Drying Stage

Raw materials with high moisture content are fed into the drum type dryer. Inside the drum, the material comes into full contact with high-temperature hot air, which quickly evaporates excess moisture. This process brings the material to a uniform and safe moisture content suitable for granulation.

3. Raw Material Crushing

After drying, the straw segments are fed into a hammer mill, where high-speed rotating hammers strike them into finer straw powder. The objective is to crush the raw material to a smaller particle size, which is crucial for subsequent conditioning and pelletizing. This forms the foundation for ensuring pellet quality and production yield.

4. Pelletizing Process

The tempered material is continuously and uniformly fed into the ring die chamber of the straw pellet mill. Under immense mechanical pressure, the material is forcibly squeezed through the die holes by the rollers, which forms dense cylindrical strands. These strands are then cut by external blades into pellets of a predetermined length.

5. Cooling System

Pellets emerging from the straw pellet mill are hot and soft, so they should be immediately fed into the counter-flow cooler. Cold air rapidly cools them to room temperature. This process sets the pellets’ shape, reduces moisture content, and hardens them for easier storage and transportation.

6. Screening Stage

The cooled pellets contain a small amount of powder generated during transportation. They then enter the vibrating screen for separation. The vibrating screen separates qualified pellets and returns the screened fine powder to the conditioner for regranulation, which reduces material waste and improves yield.

Complete Straw Pellet Production Line Equipment

RICHI Machinery not only offers straw pellet mills for sale but also provides complete straw pellet processing equipment.

Bale Breaker

It is an industrial machine specifically designed to automatically untangle and separate bundled materials.

Straw Crusher

The straw bales are broken up and shredded into shorter segments to prepare them for fine crushing.

Hammer Mill

The crushed straw is ground into fine powder (typically less than 5mm in size), which serves as the foundation for the compression molding process.

Screw Conveyor

It conveys crushed straw powder horizontally or at an incline in a sealed manner.

Drum Dryer

If the moisture content of raw materials is too high (>18%), a dryer must be used to reduce it to the ideal range of 12%-18%. This is one of the most energy-intensive sections of the production line.

Counterflow Cooler

The pellets emerging from the straw pellet mill reach temperatures of 70-90°C and possess a soft texture. They must be cooled and dehumidified to harden and set their shape.

Vibrating Screen

The fine powder and debris generated during the cooling process are screened out to ensure the purity of the finished pellets. The screened-out fine powder can be recovered and reused for pelletization.

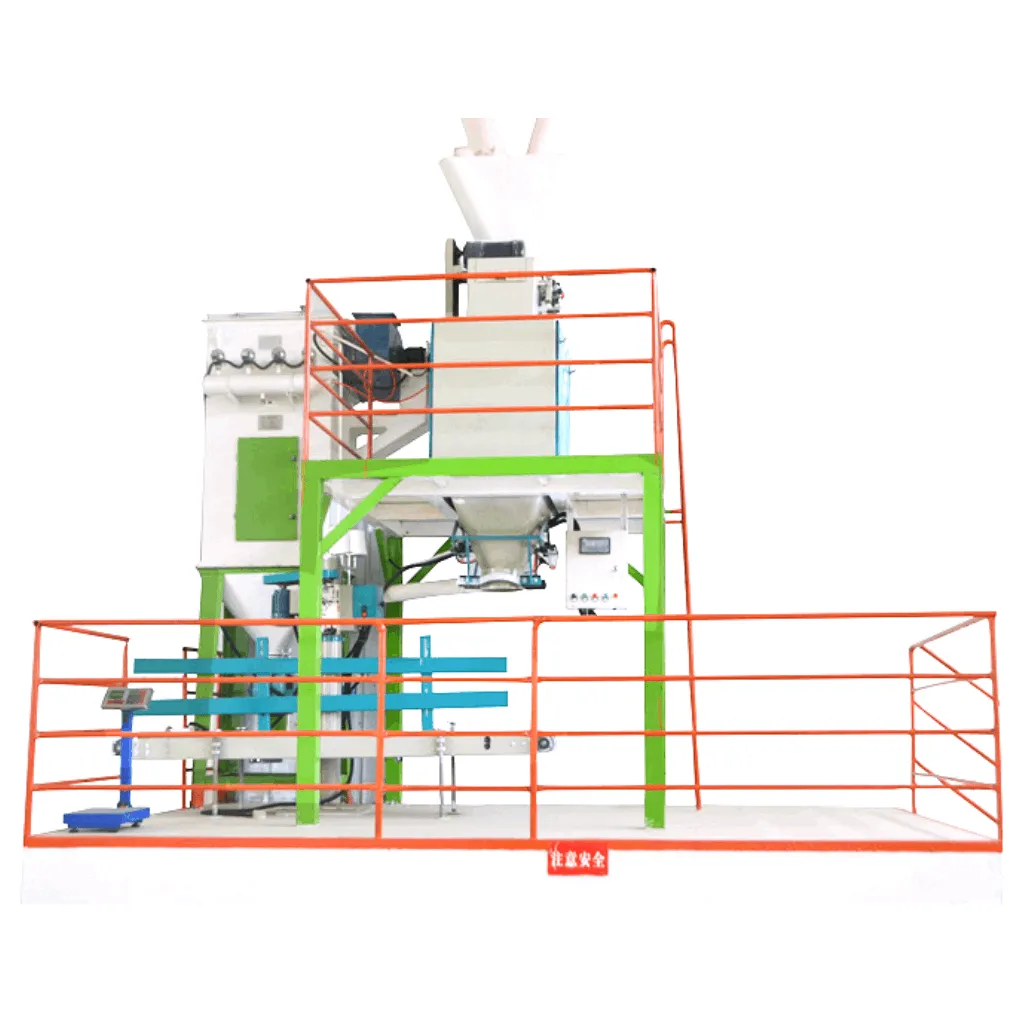

Automatic Packing Scale

The finished granules are weighed, packaged, and sealed according to predetermined weights for convenient storage and transportation.

About rICHI

RICHI Machinery was established in 1995 and holds European CE certification, Swiss SGS certification, French BV certification, and ISO 9001 quality management system certification, with a complete international trade system. To better serve our global customers, We have also launched multiple platforms including Alibaba International, Google Ads, Made-in-China.com, and SEO optimization, and own a comprehensive cross-border e-commerce operation system. Up to now, our products have been exported to 108 countries and regions across Europe, the Americas, the Middle East, Asia, Africa, and Southeast Asia, which has earned the trust and recognition of a wide range of customers.

Information Sharing

Customized Solutions

After-Sales Service

Professional Certification

Frequently Ask Question

What raw materials can be used to produce straw pellets?

+

Almost all agricultural waste can be used, such as corn stalks, wheat straw, rice straw, bean stalks, peanut shells, rice husks, cotton stalks, etc. Forestry waste like wood chips and sawdust also serves as high-quality raw material.

What are the specific requirements for raw materials?

+

- There are two main points:

- Particle size must be crushed to less than 3-5 millimeters.

- Moisture content must be strictly controlled between 12% and 18%. Too high or too low will prevent proper molding.

What is the price of a straw pellet mill?

+

The actual price of a straw pellet mill for sale depends on your specific selection. Pricing is determined by automation level and production capacity. Higher production capacity results in a higher price. For example, the guide price for a 0.3-2 tons/hour straw pellet mill ranges from $37,000 to $62,000, while a 0.5-4 tons/hour model ranges from $80,000 to $200,000, and so on. If you have specific requirements regarding output capacity, raw materials, etc., please contact us for a customized quote.