Wood Pellet Machine

RICHI MACHINERY

What Is A Wood Pellet Machine?

A wood pellet machine is a specialized biomass processing device used to compress prepared wood materials into uniform, high-density fuel pellets. By applying high pressure and friction inside the chamber, materials such as sawdust, wood chips, shavings, bark, and forestry residues are compacted into stable, low-moisture pellets with high calorific value.

This process significantly improves the recycling efficiency of wood waste, turning a wide range of biomass residues into clean and renewable energy. The resulting pellets are environmentally friendly, easy to transport and store, and suitable for long-term continuous fuel supply.

With stable performance, low operating costs, and continuous working capability, the wood pellet mill is widely used in boiler heating systems, household pellet stoves, biomass fuel plants, and regional centralized heating projects.

Technical Specifications & Model Of Wood Pellet Machine For Sale

Choosing the right wood pellet machine starts with understanding its technical specifications and model range. To meet the needs of different farm sizes and wood pellet plant capacities, we offer multiple models with varying outputs, power configurations, ring die sizes, and applicable raw materials. Whether you need small-scale production equipment or are planning a large-scale automated pelleting line, we can help you quickly find the most suitable model. The wood pellet machine price ranges from $10,000 to $90,000, depending on the model, capacity, and configuration.

MZLH320 Wood Pellet Machine

- Capacity: 0.2-0.3T/H

- Main Motor Power: 22KW

- Price: 10,000-20,000 USD

MZLH350 Wood Pelletizer

- Capacity: 0.3-0.5T/H

- Main Motor Power: 37KW

- Price: 20,000-25,000 USD

MZLH420 Pellet Machine Wood

- Capacity: 1-1.2T/H

- Main Motor Power: 90KW

- Price: 25,000-35,000 USD

MZLH520 Wood Pellet Mill

- Capacity: 1.5-2T/H

- Main Motor Power: 132KW

- Price: 40,000-50,000 USD

MZLH678 Wood Pellet Machine

- Capacity: 2.5-3T/H

- Main Motor Power: 200KW

- Price: 60,000-70,000 USD

MZLH768 Wood Pellet Machine

- Capacity: 3-4T/H

- Main Motor Power: 315KW

- Price: 80,000-90,000 USD

RICHI MACHINERY

How Wood Pellet Machines Produce Wood Pellets

Wood pellet machines play a key role in the pelletizing stage of biomass fuel production. After the raw materials are crushed and dried by other equipment, they enter the pellet mill, where high pressure and friction compress the prepared biomass into dense, uniform pellets.

With various machine types and output capacities available, our pellet machines can serve home heating users, small workshops, or complete industrial pellet production lines, ensuring stable and efficient pellet formation.

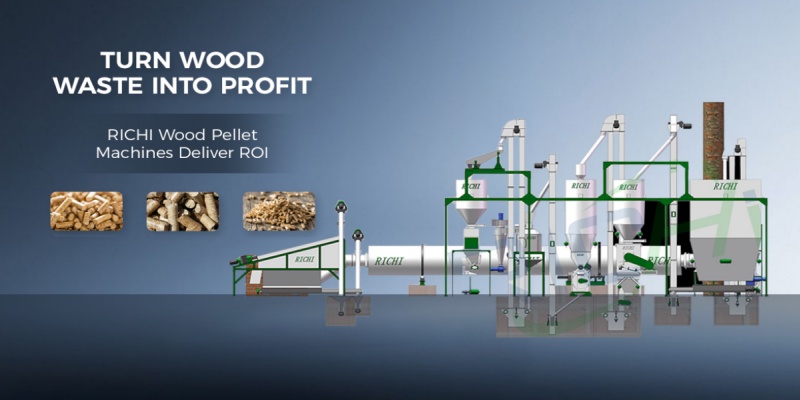

Complete Wood Pellet Production Process

The complete wood pellet production process transforms raw biomass materials into high-quality fuel pellets through a series of coordinated steps. From material preparation and crushing to drying, pelletizing, cooling, and packaging, each stage is essential for achieving uniform, dense, and efficient-burning pellets. A well-organized production process ensures stable operation, reduces waste, and maintains consistent pellet quality for various heating and energy applications.

Auxiliary Equipment for Complete Wood Pellet Production Lines

In a high-efficiency and stable wood pellet production line, the wood pellet making equipment such as crushers, mixers, coolers, sieving systems, and packing machines are just as essential as the pellet mill itself. Together, they determine raw material processing efficiency, pellet quality, and the overall automation level of the production line.

Wood Shredder Machine

A wood shredder machine reduces branches, small logs, and waste wood into smaller pieces for further processing. It is ideal for preparing materials before chipping or milling.

Drum Wood Chipper

A drum wood chipper cuts logs, slabs, and wood waste into uniform wood chips, ensuring consistent size for stable pellet production.

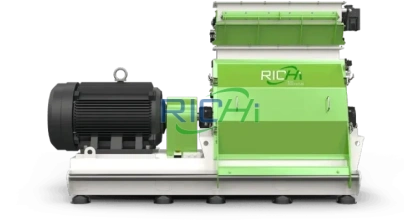

Hammer Mill

A hammer mill grinds wood chips or agricultural residues into fine powder, ensuring smooth feeding and improving pelletizing efficiency.

Dryer Machine

A dryer machine lowers the moisture content of raw materials to the ideal 12–18%, which is crucial for producing high-quality pellets.

Wood Pallet Crusher

A wood pallet crusher breaks down used pallets, boards, and bulky wood waste into smaller pieces for recycling or pellet production.

Pellet Cooler Machine

A pellet cooler reduces the temperature and moisture of freshly made pellets, improving hardness and storage stability.

.png)

Vibrating Screen

A vibrating screen removes dust, fines, and unformed particles, ensuring consistent pellet quality.

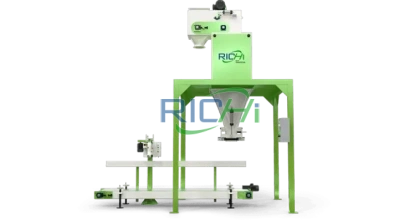

Packaging System

The packaging system automatically weighs, fills, and seals pellet bags, improving efficiency and accuracy in commercial distribution.

Related Cases Of The Wood Pellet Machine

Explore real-world applications of wood pellet machines from RICHI Machinery to see how they perform in different production scenarios. With extensive experience in designing and supplying wood pellet solutions worldwide, RICHI has delivered machines for a variety of biomass projects. These cases demonstrate the machines’ efficiency, adaptability to different raw materials, and reliability in producing high-quality pellets, providing customers with proven solutions for heating and energy production.

Video Of RICHI Wood Pellet Machine

Watch the video of RICHI wood pellet machines in action to gain a complete understanding of their production capabilities. The video illustrates how raw biomass materials such as sawdust, wood chips, and agricultural residues are processed step by step into uniform, high-quality pellets. It also highlights the machines’ efficient operation, precise pelletizing mechanism, and ability to maintain consistent pellet size and density throughout the production process.

Frequently Asked Questions

In this section, we answer the most frequently asked questions about wood pellet machines. From machine selection and raw material requirements to operation, maintenance, and troubleshooting, these answers are designed to help customers better understand the equipment and optimize their pellet production process..

–

What types of raw materials can be used for wood pellet production?

Wood pellet press machines can process a wide range of biomass materials. Commonly used raw materials include sawdust, wood chips, shavings, bark, and other wood residues. In addition, many agricultural by-products, such as straw, corn stalks, rice husks, and peanut shells, can also be pelletized.

The key is to ensure that the materials are clean, free of large impurities, and properly dried to the optimal moisture content (usually around 12–18%). Different raw materials may require slight adjustments in machine settings, such as die size or pelletizing pressure, to achieve uniform, high-quality pellets suitable for heating, industrial boilers, or energy production.

–

I’m interested in buying a wood pellet machine. How much does it cost?

The price of a biomass pellet mill for sale can vary widely depending on several factors, including production capacity, machine configuration, raw material type, and any optional features or accessories.

For small-scale or household pellet machines, prices typically start from around US $10,000. These models are compact, energy-efficient, and suitable for limited production or personal use.

For medium to large-scale industrial machines, designed for continuous production and higher output, prices can go up to around US $90,000. The final cost will also depend on your specific requirements, such as die size, motor power, and whether you need a complete production line with auxiliary equipment like dryers, coolers, and packaging machines.

–

I am planning to start a wood pellet production project. How is the production process carried out?

Producing wood pellets involves several organized steps to ensure high-quality and efficient production.

- Raw Material Preparation – Select suitable biomass materials such as sawdust, wood chips, shavings, bark, or agricultural residues. Remove large impurities and ensure uniform particle size.

- Crushing – Crush the raw materials into small, consistent particles to facilitate the pelletizing process.

- Drying – Reduce the moisture content of the crushed materials to around 12–18%, which is optimal for pellet formation.

- Pelletizing – Feed the dried materials into a wood pellet machine, where they are compressed into dense, cylindrical pellets.

- Cooling and Screening – Cool the hot pellets to room temperature, then screen them to remove fines or broken pieces.

- Packaging – Package the finished pellets for storage, transport, or sale.

–

I want to produce pellets from a mix of sawdust and rice husks. Can the same machine handle different raw materials?

Yes, a wood pellet machine can handle different biomass materials, including mixed raw materials such as sawdust and rice husks. However, because each material has different characteristics—such as bulk density, fiber structure, and ash content—you may need to adjust certain parameters to achieve stable pelletizing.

For example, sawdust has good fiber bonding ability, while rice husks have higher silica content and are more difficult to compress. When mixing them, you may need to fine-tune moisture levels, adjust feeding speed, or choose a more suitable ring die compression ratio.

RICHI pellet machines are designed to work with a wide range of materials, and our engineers can help you set the right configuration to ensure the mixture produces strong, durable, and uniform pellets.

–

How do I choose the right wood pellet machine for my production needs?

Choosing the right pellet machine depends on several key factors related to your raw materials, production goals, and operational conditions:

- Raw material type: Consider what biomass materials you plan to use (e.g. sawdust, wood chips, agricultural residues), because different materials have different fiber content, moisture requirements, and compressibility. Ensure the machine you choose supports those materials.

- Required output capacity: Decide how much pellet output you need per hour or per day. For small-scale or household use, a low-capacity machine may suffice. For commercial or industrial production, you’ll need a higher-capacity model.

- Die type and machine configuration: Different machines (e.g. ring die vs. flat die) and configurations are better suited to different scales and materials. The die design influences pellet quality and production stability.

- Power supply and energy efficiency: Check the power requirements and energy consumption, especially if you are in a region with limited electricity or want to reduce operational costs.

- Budget and additional equipment needs: Apart from the pelletizer itself, you may need auxiliary equipment such as crushers, dryers, coolers, and packing systems. Your budget should reflect the cost of a complete production line if you aim for continuous production.

- Maintenance, after-sales support, and machine reliability: A robust, well-supported machine ensures long-term stable operation. Choose a manufacturer with good reputation and technical support, ensuring parts replacement and maintenance are manageable.

By evaluating these factors carefully, you can select a wood pellet machine that matches your raw materials and production goals, ensuring efficient, stable, and cost-effective pellet production.