Wood Pellet Making Machine Price

The wood pellet making machine price depends on its specific model, production capacity, and configuration. We have designed multiple pelletizer models with production capacities ranging from 0.5 to 8 T/H, which can produce wood pellets with diameters ranging from 4 to 12 mm. As production capacity increases, so does the price. High-capacity equipment is usually customized to provide more efficient and stable production.

Different Models of Wood Pellet making Machine

The model is the primary factor influencing the wood pellet making machine price. We offer six basic production capacity models, and can provide customized configurations based on your specific production requirements. For instance, we offer multiple ring die hole sizes and can customize molds with specific parameters. The final price is determined by considering all these factors.

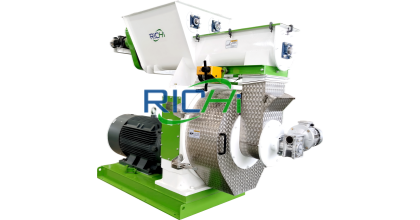

MZLH320 samll wood pellet machine

The pelletizer has a production capacity of 0.5–0.6 T/H and a main motor power of 22 kW. It is primarily intended for small-scale pellet production, with an indicative price of $15,100.

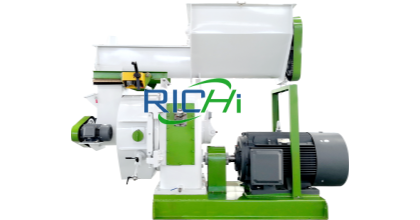

MZLH350 wood pellet making machine

This flexible equipment is suitable for small to medium production capacities of 1.0–1.2 T/H, which motor power is 37 kW. The estimated investment cost is around $20,500.

MZLH420 biomass wood pelletizer

This medium-capacity pelletizer has a main motor power of 90 kW, and can pelletize more complex materials at a rate of 1.8–2.0 T/H. The reference price is $29,600.

MZLH520 wood pellet press machine

This is the most popular 2.8–3.0 T/H capacity pelletizer, capable of efficiently processing complex materials and stable output. The reference price for this model is $45,100.

MZLH678 large wood pellet mill

The model has a production capacity of 4–5 T/H and is primarily offered as a customizable, long-term solution for large-scale, continuous production. The investment budget is $67,100.

MZLH768 wood pelletizer machine

This is a fully customizable solution designed to meet higher production capacity requirements of 6–8 T/H. It has low raw material requirements and an investment cost of around $80,500.

Because RICHI’s technology is constantly being updated and iterated, we will continuously upgrade and innovate our equipment. Therefore, the specific equipment parameters are subject to the actual quotation. We will provide more professional customized design and production services for each customer.

Which Solution Suits You Best

If you’re unsure which pellet mill to choose, we offer the following recommendations for your consideration. These solutions are based on factors such as production capacity, raw material conditions, pellet application.

Design

Small Scale wood Pellet Production

It suits small-capacity pellet mills, which require a lower investment budget. This are suitable for wood processing plants, furniture factories, and for pelleting mixed raw materials on farms.

Design

Medium Commercial Pellet Production

For medium-scale pellet production and a stable supply of raw materials, choose our production line solution. This includes crushing and packaging system, offers a higher investment return.

Design

Industrial Pellet Plant

This solution includes project planning, on-site construction, installation of equipment, operational training and others. It is ideal for rapid start-up and efficient return on investment.

Design

Sawdust Pellet Solution

If your main raw material is sawdust, we can provide you with cost-effective sawdust pellet machine. However, if the moisture content exceeds 18%, we recommend adding drying equipment.

Design

Wood Chip Pellet Solution

In addition to the basic pelletizer, you can configure wood chippers and crushers based on your raw material requirements. This wood pellet making machine price is also highly competitive.

Design

Complete Pellet Production Line

It is suitable for large-scale production, such as at wood pellet plants, and for other manufacturers requiring a high investment return. High levels of automation mean efficient production.

Global Projects for Wood Pellet making Machines

Wood pellet production project in Romania

Project Investment: $68,000 USD

This client is a startup factory requiring a small-capacity pelletizer with a throughput of 2 T/H, along with other raw material processing equipment. This wood pellet production line solution enables the client to convert large quantities of branches and sawdust into high-quality fuel pellets.

Project Investment: $50,000 USD

For this project, we provided the client with a small-capacity, flexible pelletizer of 1-2 T/H. Based on the client’s raw material conditions, we also configured a drying drum and packaging equipment. These address the raw material handling and pelletizing challenges.

wood pellet plant project in Canada

Project Investment: $100,000 USD

This turnkey solution has a production capacity of 3–4 T/H. The client requires highly automated wood pellet manufacturing equipment. The wood pellet making machine price for this solution is $45,100, meeting demands for both high output and superior quality.

wood pellet production line for sale in uSA

Project Investment: $300,000 USD

This client is a large wood pellet plant, requiring a high-capacity 10T/H production line. The solution includes complete production equipment and a high level of automation. This significantly increases production efficiency, while substantially reducing labor costs.

Wood Pellet Machine Operation Video

The wood pellet making machine price also depends on its automation level. A highly automated pelletizer offers greater convenience and a higher investment return. This video demonstrates the automated production process.

Application Scenarios for Different Models of wood Pellet making Machines

Branch pellets

log pellets

Wood chip pellets

wood shaving pellets

Mixed wood pellets

Bark wood pellets

Why Choose RICHI?

As an advanced pellet machine supplier, we offer diverse production solutions. Here, you will find competitive wood pellet making machine price and high-return production line packages. The production line price depends on your specific configuration needs and the type of project service required. With project experience spanning over 150 countries and regions worldwide, we provide customized equipment and turnkey project services. Choose RICHI to find your highest-yield solution for 2026.

Customized equipment

Our professional engineering team can provide bespoke equipment tailored to your specific requirements. This is based on factors such as your raw material ratios, target production capacity and actual application requirements. We also offer a comprehensive long-term after-sales service including a one-year warranty, global access to spare parts, and ongoing technical support.

Production Line Solution

If you require a complete wood pellet production line, we are equally able to provide. This includes fundamental process configurations such as crushing, drying, pelletizing, cooling, screening and packaging. In addition to standalone equipment, we have designed convenient auxiliary devices. For rapid production ramp-up, choose our turnkey solution.

Frequently Asked Questions

Drawing on our extensive experience in global customer service, we recognize your uncertainties and concerns when choosing a pelletizing machine. Therefore, we have compiled some useful reference information. If you have any further questions about wood pellet making machine, please provide details of your production capacity, raw materials and application scenarios.

+

What are the factors affecting the wood pellet making machine cost?

The key factors are production capacity, structural configuration and automation level. For small-scale pellet production above 0.5 T/H, you can select a compact pelletizer model. At the same time, configure the appropriate ring die apertures and make the necessary parameter adjustments. This approach requires minimal investment and is suitable for low-budget scenarios.

As production capacity increases, so do pelletizer prices. Different pellet sizes require ring dies with different hole diameters. For large-scale pellet producers, fully automated production reduces labor costs. Although this option is more expensive, it offers the best cost-effectiveness and high return on investment.

+

What is the small wood pellet making machine price?

Small-to-medium pelletizers have capacities of 0.5–0.6 T/H and 1.0–1.2 T/H. The reference price range for these machines is $15,100–$20,500. The final quote will depend on your chosen configuration of equipment. This type of pelletizer is suitable for small woodworking shops, furniture factories, farms or individuals requiring fuel for personal use.

Due to the basic configuration of this equipment, it has higher requirements for raw materials. Therefore, you must ensure that the raw material size is within 3–5 mm and that the moisture content does not exceed 15–18%.

+

How much does an industrial-grade wood pellet making machine cost?

Large-scale wood pellet mills have capacities of 4–5 T/H and 6–8 T/H, with reference prices ranging from $67,100 to $80,500. Similarly, the final price depends on the final equipment configuration. These pellet mills are typically customized solutions.

They are suitable for industrial wood pellet production lines, biomass pellet plants, and manufacturers of pellet products for export. Due to the high level of configuration, they demonstrate strong adaptability to various raw materials. They not only ensure stable output, but also accommodate multiple raw material pelletizing solutions.

+

What information is required to obtain an accurate wood pellet making machine price?

Based on the factors that influence the price of this pelletizer, you need to provide details such as raw material type, moisture content, production capacity, pellet size and application scenario. With this information, we can recommend suitable models and configurations. Providing valid basic information helps us deliver a quick quote, saving you time.