Wood Pellet Press For Sale

RICHI wood pellet press for sale is designed for stable operation, high output, and low production cost—helping you build a profitable and sustainable pellet business for fuel, heating, and industrial energy markets.

What Is a Wood Pellet Press?

A wood pellet press is a machine that converts sawdust, wood chips, and other wood waste into high-density biomass fuel pellets. By turning low-cost raw materials into valuable renewable energy products, it enables efficient, low-cost, and profitable pellet production for heating, power generation, and industrial use.

The wood pellet press is suitable for a wide range of wood-based raw materials, including sawdust, wood chips, wood shavings, wood waste, and forestry residues. Both softwood and hardwood can be processed smoothly after proper crushing and moisture adjustment. For stable pelletizing performance and consistent pellet quality, the recommended moisture content of raw materials is 12%–18%.

Pre-treated wood materials are fed into the ring die pelletizing chamber, where rotating rollers apply high pressure and friction to compress the material through the die holes. During pellet formation, the natural lignin in the wood is released and acts as a binder, allowing dense pellets to be formed without chemical additives. The finished pellets are then discharged and cut to the required length automatically.

- Capacity: 0.2–4 t/h

- Pellet Diameter: 6–12 mm

- Applications: Biomass fuel, heating systems, industrial boilers, biomass pellet plant

- Price Range: USD 10,000–90,000

Working Video Of Wood Pellet Press For Sale

See our wood pellet press in action! Watch how raw materials like sawdust, wood chips, and leaves are efficiently processed into high-quality pellets. These videos showcase real operation, stable output, and consistent pellet quality, helping you understand the performance and reliability of our machines before making a purchase.

Suitable Raw Materials for Biomass Wood Pellet Press

Choosing the right wood pellet press for sale starts with understanding raw material compatibility. Our machines are designed to efficiently process a variety of common wood-based materials, allowing users to convert different forms of wood resources into high-density biomass pellets.

Sawdust

Wood chips

Logging residues

Furniture factory waste

In addition to wood materials, our biomass pellet mill for wood can also be adapted for selected biomass raw materials with similar properties.

Different Types of Wood Pellet Press for Sale

To meet different raw material characteristics and production requirements, our wood pellet press for sale is available in several application-based types. According to the form, size, and processing conditions of the raw materials, additional configurations and component options are applied to ensure stable operation and optimal pellet quality. This allows each type of pellet press to be better matched to specific wood materials and production needs.

Wood Chip Pellet Machine

Designed for crushed wood chips and forestry residues, this type of wood pellet machine is suitable for medium to large-scale pellet production with stable output and high efficiency.

Sawdust Pellet Making Machine

This sawdust pellet machine for sale is optimized for fine wood materials such as sawdust and wood shavings, delivering dense pellets with smooth surfaces and consistent quality.

Wood Pellet Press machine for Logs

This type of wood pellet machine is configured for processing logs and branches after crushing, making it suitable for integrated pellet lines that start from raw wood materials.

Waste Wood Pellet Press for Sale

Designed for recycling pallets, offcuts, and scrap wood, this wood pellet machine converts wood waste into valuable biomass fuel pellets, improving material utilization and profitability.

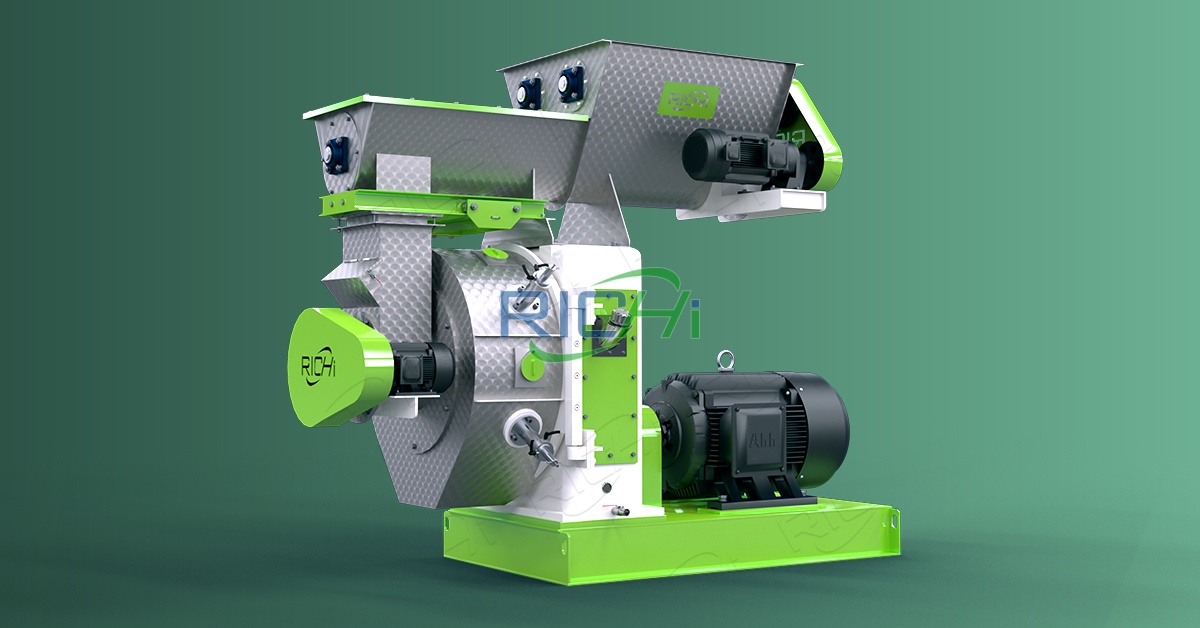

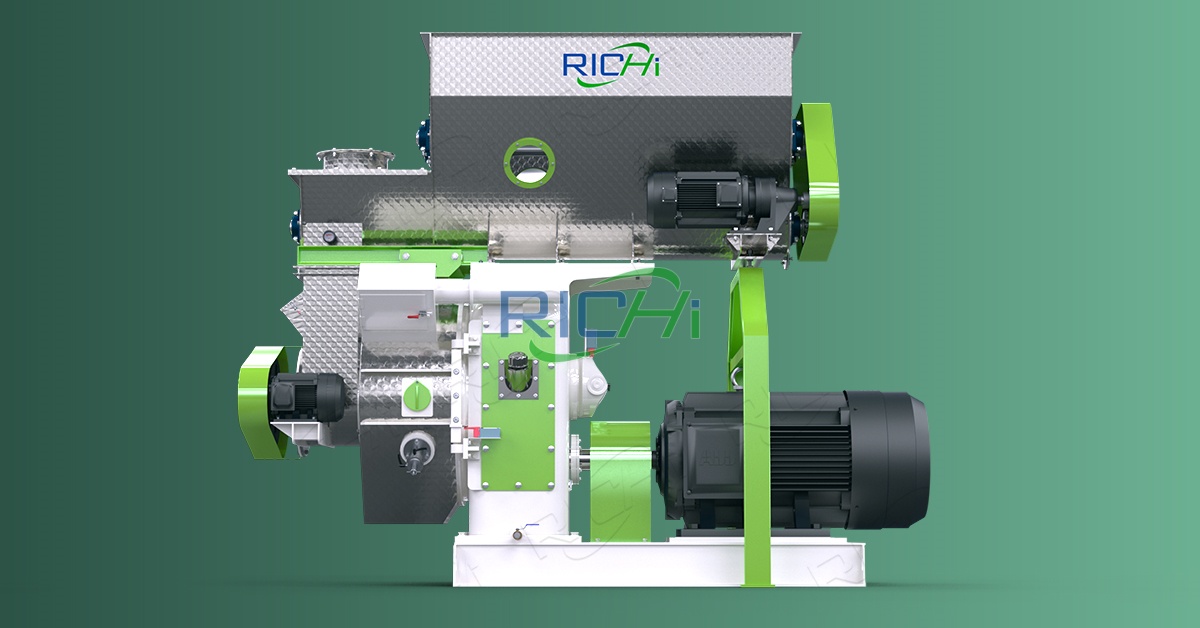

Key Components of Our Wood Pellet Press For Sale

The performance, durability, and pellet quality of a sawdust pellet press largely depend on the quality of its core components. Our machines are built with carefully selected, industrial-grade parts to ensure stable operation, high efficiency, and long service life, even under continuous production conditions.

Core Stainless Steel Parts

Our pellet press uses high-quality stainless steel for critical components, ensuring durability, corrosion resistance, and long service life. This guarantees stable operation even under continuous production.

High-Precision Ring Die

The industrial-grade ring die delivers uniform pellet density and high output. Its precision design ensures consistent pellet size and reduces maintenance frequency, maximizing production efficiency.

Siemens Motor

Equipped with a Siemens motor, our pellet press for wood provides stable, energy-efficient operation with low vibration. International brand reliability ensures continuous, trouble-free production.

Electric Control Cabinet

The advanced electric control cabinet allows simple, safe, and intelligent operation. Operators can monitor machine status, adjust settings, and protect the system from overload or malfunction.

Technical Parameters Of Wood Pellet Press For Sale

Understanding the key technical parameters is essential when selecting a wood pellet press for sale. Our machines are available in multiple models with capacities ranging from 0.2 to 4T/H, catering to both household heating use and commercial pellet production. The detailed specification table provides information on capacity, power, pellet diameter, and price range, helping customers efficiently choose the right machine for their production needs.

MZLH320 Wood Pellet Press For Sale

- Capacity: 0.2-0.3T/H

- Pellet size: 4-12mm

- Main Motor Power (kW): 22

- Broken Arch Feeder Power (kW): 2.2

- Forced Feeder Power (kW): 0.75

- Ring Die Inner Diameter (mm): 320

- Price: $10,000-$20,000

MZLH350 Wood Pellet Press Machine

- Capacity: 0.3-0.5 T/H

- Pellet size: 4-12mm

- Main Motor Power (kW): 37

- Broken Arch Feeder Power (kW): 2.2

- Forced Feeder Power (kW): 0.75

- Ring Die Inner Diameter (mm): 350

- Price: $20,000-$30,000

MZLH420 Wood Pellet Machine

- Capacity: 1.0-1.2 T/H

- Pellet size: 4-12mm

- Main Motor Power (kW): 90

- Broken Arch Feeder Power (kW): 3

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 420

- Price: $30,000-$40,000

MZLH520 Wood Pellet Mill

- Capacity: 1.5-2.0 T/H

- Pellet size: 4-12mm

- Main Motor Power (kW): 132

- Broken Arch Feeder Power (kW): 3

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 520

- Price: $40,000-$50,000

MZLH678 Wood Pellet Press For Sale

- Capacity: 2.5-3.0 T/H

- Pellet size: 4-12mm

- Main Motor Power (kW): 185

- Broken Arch Feeder Power (kW): 3

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm):673

- Price: $50,000-$100,000

MZLH768 Wood Pellet Making Machine

- Capacity: 3.0-4.0 T/H

- Pellet size: 4-12mm

- Main Motor Power (kW): 250

- Broken Arch Feeder Power (kW): 4

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 762

- Price: $60,000-$100,000

RICHI Wood Pellet Press For Sale Global

With over 30 years of experience in designing and manufacturing wood pellet making equipments, RICHI has successfully delivered projects in more than 140 countries and regions worldwide. Our machines are trusted by customers around the globe for their high-quality pellets, stable performance, and reliable after-sales support, making RICHI your ideal partner for biomass pellet production.

Wood Pellet Machine In India

- Capacity: 1-2T/H

- Raw Materials: Wood chips, sawdust, and small wood residues.

- Background: A small community in southern India needed a compact wood pellet production system for household heating. The project aimed to utilize local wood waste efficiently while reducing dependency on LPG and coal.

- Customer Feedback: The customer reported stable pellet production with minimal maintenance. Pellets are consistent in size and burn efficiently, meeting all household heating needs.

Wood Pellet Press For Sale Indonesia

- Capacity: 2T/H

- Raw Materials: Palm residues and wood chips.

- Background: A small biomass energy project in Indonesia sought to convert palm industry residues into renewable pellets for local heating and small-scale commercial sales.

- Customer Feedback: The machine performed reliably with high pellet density. Customers were satisfied with low energy consumption and minimal ash content.

Wood Pellet Mill In Canada

- Capacity: 2-3T/H

- Raw Materials: Softwood sawdust and forestry residues.

- Background: A Canadian company aimed to produce pellets for residential heating and local biomass energy projects. The goal was to use abundant forestry by-products efficiently.

- Customer Feedback: The equipment ran smoothly with consistent output. Pellets are high quality and widely accepted by local heating systems.

Wood Pellet Press For Sale Australia

- Capacity: 3-4T/H

- Raw Materials: Hardwood chips, sawdust, and mixed wood residues.

- Background: An Australian renewable energy project needed pellets for industrial boilers and small commercial heating. The focus was on high-quality pellets from mixed wood waste.

- Customer Feedback: The customer praised the machine for high output and low maintenance. Pellets burn evenly and meet industrial heating requirements.

Complete Wood Pellet Plant In America

- Capacity: 10T/H

- Raw Materials: Softwood sawdust and wood chips.

- Background: A medium-scale pellet factory in the US Midwest wanted a reliable production line to supply residential and commercial heating markets.

- Customer Feedback: The wood pellet plant for sale America achieved stable high-capacity production. Pellets meet market standards for density and moisture, ensuring good sales performance.

Wood Pellet Production Line In Bangladesh

- Capacity: 20T/H

- Raw Materials: Mixed wood residues, sawdust, and agricultural biomass.

- Background: A large biomass wood pellet production line in Bangladesh required high-capacity pellet production for commercial heating and energy export.

- Customer Feedback: The customer was satisfied with the high production efficiency and stable pellet quality. The machine adapted well to mixed biomass inputs.

Benefits of Wood Pellets

Wood pellets are a widely used biomass fuel made from compressed wood materials. Compared with traditional solid fuels, wood pellets offer clear advantages in energy efficiency, handling, and environmental performance, making them an attractive option for heating and industrial energy applications.

High Energy Efficiency & Clean Combustion

Wood pellets have a calorific value of 4,500–5,000 kcal/kg, providing stable heat output. Compared with traditional solid fuels, they produce 50–70% less ash and emissions, making them a clean and efficient energy source.

Easy Storage & Transportation

Standardized pellets with a diameter of 6–12 mm and uniform density are easy to store, transport, and handle. Using bulk storage and pneumatic transport can reduce logistics costs by up to 30% compared with irregular wood fuel.

Renewable & Environmentally Friendly

Made from wood waste, forestry residues, and other suitable biomass, wood pellets convert low-value materials into renewable energy. Using pellets for heating or power generation can reduce net CO₂ emissions by up to 80–90% compared with coal.

Advantage Of Our Wood Pellet Press for Sale

Choosing the right machine is crucial for efficient, high-quality pellet production. RICHI Machinery machines combine durable materials, advanced components, and flexible capacity options to meet the diverse needs of households, small production line, and commercial pellet factories.

Customized 0.2-4.0T/H Wood Pellet Press for Sale

High-Quality Materials & Durable Design

Our wood pellet machine is built with premium stainless steel components and a high-precision ring die, ensuring long-lasting durability, consistent pellet quality, and stable operation even under continuous production.

Wide Raw Material Compatibility

The machine can efficiently process sawdust, wood chips, leaves, and other biomass materials. With a recommended moisture content of 12–18%, it allows customers to utilize a variety of low-cost raw materials for pellets.

Reliable Components & Intelligent Control

Equipped with Siemens motors, stable feeding systems, and advanced electric control cabinets, our machines ensure smooth, energy-efficient operation with minimal maintenance.

Excellent After-Sales Support

We provide installation guidance, operator training, spare parts supply, and technical support to ensure a worry-free investment and long-term operation for every customer.

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 140 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

Tailored wood pellet manufacturing equipment and production lines to meet your specific needs.

Modern Workshop

State-of-the-art manufacturing facilities ensure precision, durability, and consistent quality.

On-site Installation

Professional engineers provide installation services on-site for smooth start-up.

Information Sharing

Keep clients updated with technical knowledge, process improvements, and industry trends.

On-the-spot Training

Hands-on training ensures your staff can operate and maintain equipment efficiently.

After-Sales Service

Timely support and maintenance services to minimize downtime and maximize production efficiency.

Frequently Asked Questions About Wood Pellet Press For Sale

Have questions about buying a wood pellet press? Here we answer the most frequently asked questions to help you choose the right machine and start pellet production smoothly.

Can I use mixed raw materials for pellet production?

+

Yes. Our wood pellet press supports mixed raw materials such as sawdust, wood chips, leaves, and other biomass materials. Mixing different raw materials helps reduce production costs and improves raw material availability. For stable operation and good pellet quality, we recommend keeping the moisture content between 12–18%.

What after-sales services do you provide?

+

We provide complete after-sales support, including installation guidance, operator training, technical documentation, spare parts supply, and long-term online technical assistance. Our goal is to help customers start production smoothly and operate the equipment reliably over the long term.

Can I start with a small-capacity machine and expand later?

+

Yes. Many customers begin with a small-capacity wood pellet press machine to test the market or reduce initial investment. As demand grows, additional machines or auxiliary equipment can be added to expand production capacity step by step.

How do I choose the most suitable wood pellet press for my project?

+

The right model of wood pellet press for sale depends on factors such as raw material type, target capacity, pellet size, and application (household heating or commercial production). Our technical team can recommend the most suitable configuration based on your specific requirements, ensuring high efficiency and cost-effective operation.