WOOD PELLET pRESS MACHINE

Wood pellet press machines represent a typical type of biomass energy equipment and it is also a core equipment for converting wood waste into clean energy.

introduction for wood pellet press machine

Specifically developed for the utilization of renewable resources

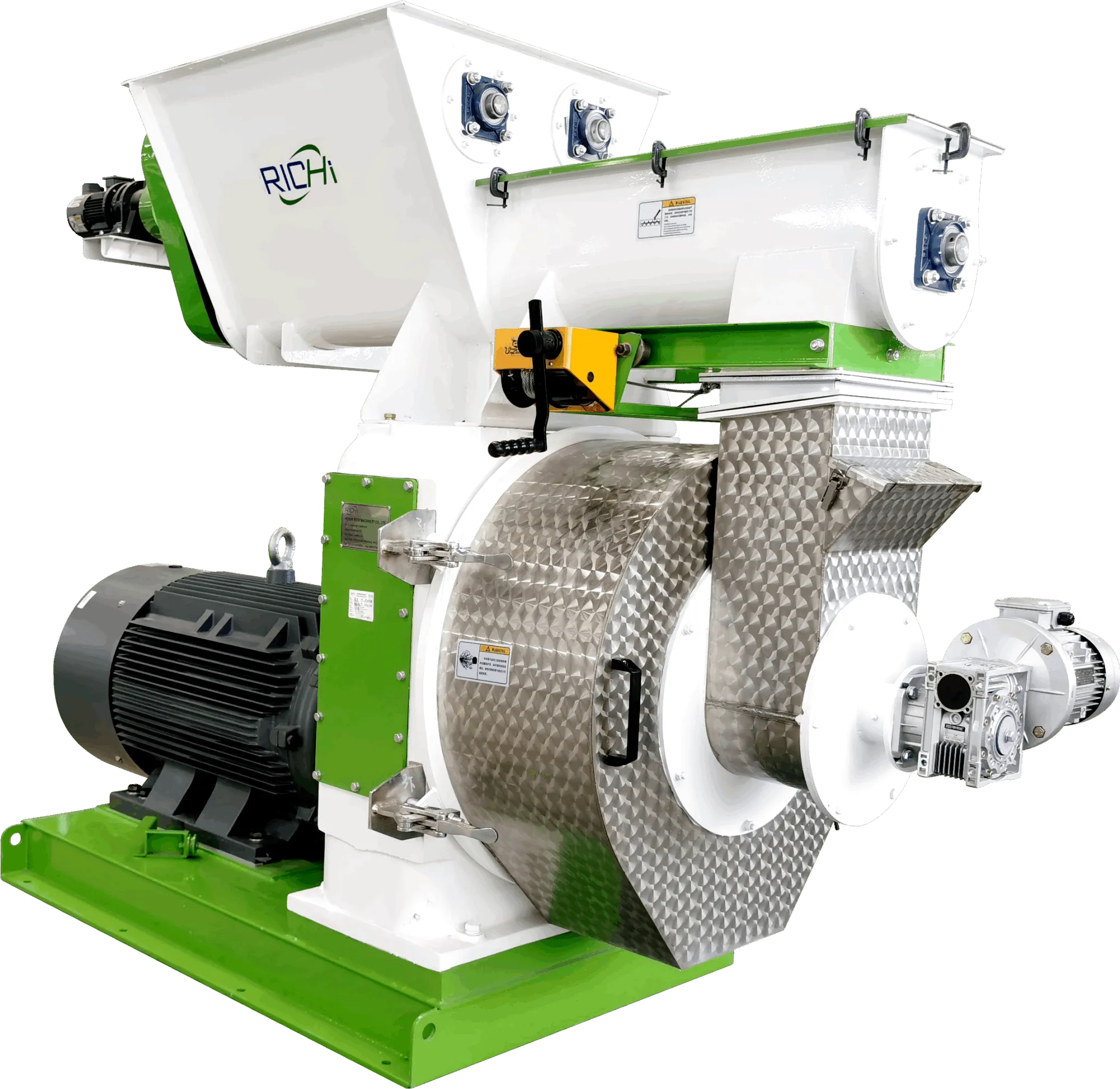

RICHI Machinery’s MZLH series wood pellet press for sale is primarily designed for processing raw materials such as wood chips, lumber, and branches into biomass pellets. It is widely used in furniture factories, wood processing plants, and other facilities for recycling. RICHI Machinery Factory possesses superior intelligent and automated technologies, therefore the productivity and product quality of our wood pellet presses for sale are at the forefront of the industry.

As an eco-friendly piece of equipment, the wood pellet press serves not only as a powerful tool for wood processing enterprises to reduce costs and increase efficiency, but also as a crucial technological tool for responding to carbon neutrality policies and developing a circular economy. The produced pellet fuel can be widely used as a clean energy source in industrial boilers, biomass power generation, and residential heating. It offers significant advantages such as high burning efficiency, convenient storage and transportation, and environmental friendliness with low carbon emissions, making it an ideal alternative to traditional fuels such as coal.

Working Principle

Let’s get to know the main working principle of RICHI Machinery’s MZLH series wood pellet press machine. The wood pellet press features a horizontally arranged ring die structure, delivering stable output, high automation, and extended service life, which is the best choice for commercial biomass pellet factories.

During this process, the wood pellet press machine employs physical compression molding technology to complete the conversion through four key steps:

- Raw Material Crushing : Crushing raw materials into particles measuring 3-5mm in size

- Moisture Adjustment : Controlling raw material moisture content within the optimal range of 13-18%

- High Temperature Compression : Forcing wood fibers to naturally bond through high-temperature, high-pressure extrusion through molds

- Molding and Cooling : Cutting into shape followed by cooling to improve pellet durability

RICHI MACHINERY

Core Components Display

Next, let’s explore the core components of RICHI Machinery’s MZLH series wood pellet press machine. We design each unit with high quality materials, such as stainless steel construction, Siemens motors, and SKF bearings, which ensures the wood pellet press’s high efficiency, stability, and excellent results.

RICHI MACHINERY

Price for Wood Pellet Press Machine

The price of RICHI wood pellet press for sale depends on their model, output capacity, and configuration. Generally, the range in price from $10,000 to $100,000.

Small-scale equipment

(Suitable for Individual Entrepreneurs/Small Scale Production)

- Production Capacity: 300 -700kg/h

- Price Range: ¥10,000 – ¥30,000

- Features: Simple operation, compact footprint

Mid-scale Equipment

(Suitable for Small and Medium Enterprises)

- Production Capacity: 1-2.5 t/h

- Price Range: ¥30,000 – ¥60,000

- Features: High automation, stable output, fast return on investment

Large-scale Equipment

(Suitable for Mass Production)

- Production Capacity: 2.5 – 4.5 t/h

- Price Range: ¥60,000 – ¥100,000

- Features: Fully automated control, high output, low operating costs

Model Specifications for wood pellet press machine

The following are the specifications for the ring die wood pellet press machine. If you are unsure how to select the appropriate model, please contact us directly.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power(kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Feeding Device Power (kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Mold Inner Diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Pellet Diameter (mm) | 4~12 | |||||

| Capacity (T/H) | 0.2-0.3 | 0.3-0.5 | 1.0-1.2 | 1.5-2.0 | 2.5-3.0 | 3.0-4.0 |

Core Advantage of Wood Pellet Press Machine

Next, let us introduce the six core advantages in detail, showing you how our wood pellet manufacturing equipment can achieve dual improvements in economic and environmental benefits.

High Output And Low Energy Consumption

Wide Range of Applications

Our equipment has been successfully deployed across diverse sectors including wood processing, renewable energy, residential and industrial heating, and agriculture. Regardless of your industry, whenever biomass material processing is involved, we deliver the most suitable solutions.

Efficiency and Environmental Protection

This wood pellet machine employs advanced pelleting technology to efficiently convert crushed wood materials into dense wood pellets, which becomes a clean energy source, significantly improving energy utilization. Furthermore, the raw materials for the final pellets come from natural wood waste such as wood shavings and branches. These materials inherently contain no harmful elements like sulfur or phosphorus, and no chemical additives are required during the wood pellet production process.

Stable Performance

The wood pellet press machine employs variable-frequency feeding to effectively prevent uneven feeding caused by voltage fluctuations. Equipped with a high-performance Siemens motor and an advanced control system, it ensures long-term stable and reliable operation with minimal downtime.

Automatic Control

The wood pellet press machine is equipped with a one-button start/stop design, and its advanced automatic control system makes operation more convenient and straightforward. It also features a visual interface that displays real-time equipment status, which allows operators to easily monitor the production process and adjust operating parameters to ensure efficient production operations.

Customized Solutions

Our professional engineers can provide granulation solutions based on your specific requirements—such as budget, raw materials, factory layout, and production needs. You can adjust production capacity and speed according to your operational demands.

wood pellet press machine Cases

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises. Now we have successfully assisted over 300 enterprises in achieving resource utilization of wood waste, processing more than 1 million tons of waste in total and generating hundreds of millions of yuan in additional revenue for our clients.

Wood Pellet Press Machine in Romanian

- Time: 2022

- Region: Europe

- Output: 5T/H

- Background: Specializing in solid wood furniture, the facility generates 50 tons of wood waste daily. High disposal costs and significant environmental pressure need a solution.

Romania has a wide range of forest areas, and wood chips generated during wood processing can be transformed into high-quality raw materials for biomass fuel through our technology. When this Romanian client chose RICHI, we responded promptly. We provided a complete solution—from equipment manufacture to the layout, and from installation and test to after-sales service, which fully supported the client’s path to success.

Wood Pellet Press Machine in Vietnam

- Time: 2023

- Region: Southeast Asia

- Output: 2T/H

- Background: Daily generation of over 20 tons of wood waste such as sawdust. Site constraints limit space, with waste piles occupying large areas.

The customer clearly requested that only 100% wood chips be used as raw material. Therefore, this production line includes four key systems: pretreatment, cooling, sieving, and pelletizing. It is equipped with the sawdust flash dryer, the sieving machine, the sawdust pellet machine, the wood pellet cooler, and the packaging machine, which can meet the entire production requirements.

Wood Pellet Press Machine in Slovak

- Time: 2024

- Region: Europe

- Output: 10T/H

- Background: Wood utilization rate is only 65% with large quantities of high-quality scrap wood for disposal.

Slovakia is a country in central Europe, with its land approximately 40% covered by forests. Wood-processing industry there share a relatively big market. After wood processing, there are abundant sawdust residues, which can be re-processed and made into biomass pellet. With our wood pellet press machine installed in Slovakia, wood sawdust can be made into pellet locally, which features economic benefit, social benefit and ecological benefit.

The above case studies clearly demonstrate that wood pellet press machines are not only waste disposal equipment, but also vital tools for enterprises to upgrade their operations and enhance competitiveness. Whether you are a wood processing company or a furniture manufacturer, we can provide the most suitable solutions to help you achieve a double win in both economic and environmental benefits!

Why Choose RICHI Machinery

Since 1995, RICHI Machinery has served thousands of customers across more than 109 countries and regions worldwide. Our products are exported to high-end markets including the Middle East, South America, Africa, Southeast Asia, and Europe, and have received numerous high praises.

Customized Solutions

We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

Modern Workshop

We have a modern production facility, which are able to efficiently and precisely manufacture each animal feed pellet press for you.

On-site Installation

Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

Information Sharing

During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the feed pellet presses are finished, we’ll deliver them safely and punctually to your appointed place.

On-the-spot Training

During the testing process, our engineers will provide your employees with on-the-spot training that includes equipment operation, daily service, and common fault resolution.

After-Sales Service

RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond.

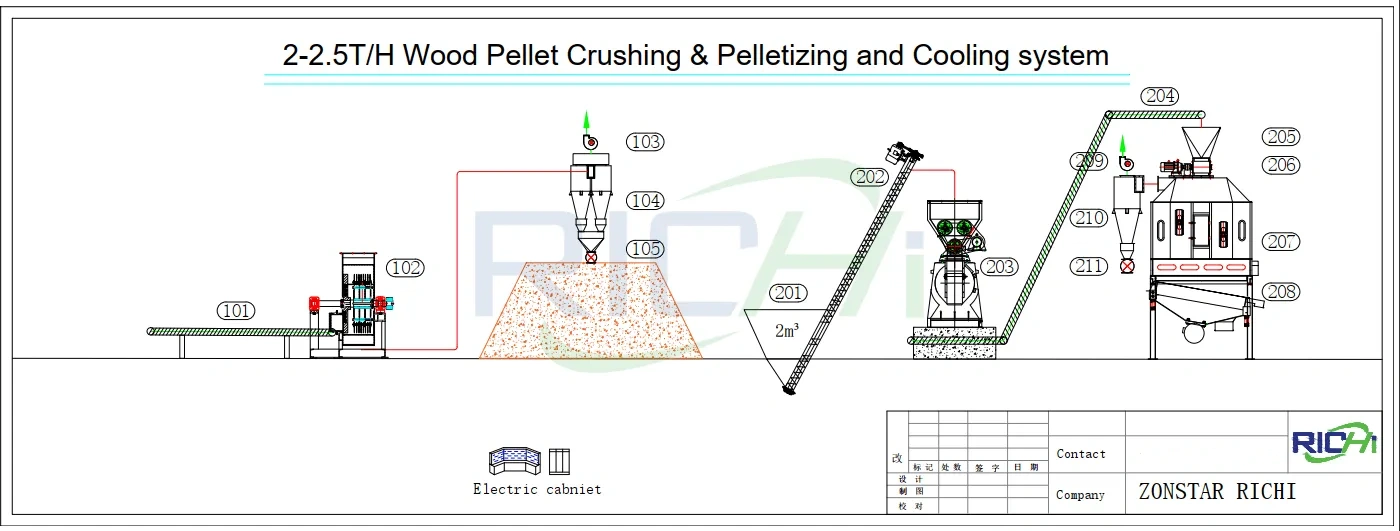

Full-Process Wood Pellet Production Line

Here I will take raw material as logs as an example and introduce you the process of 2-2.5T/H complete wood pellet plant in detail. The production process for wood pellet lines does not adhere to a fixed standard; production techniques, equipment configurations, and manufacturing technologies can all be customized to meet your specific requirements.

1.Wood chipping

First of all, the logs enter the chipper through the conveying equipment, the chipper can cut the logs to 3-5mm thin wood chips, which is convenient for the subsequent crushing process, and also beneficial to the drying of raw materials.

2.Wood crushing

This step is fundamental to ensuring effective pellet formation. For different types of raw materials, the equipment is provided with different specialized crushing devices. Finally, all raw materials are transformed into powdered material with a particle size of 3-5mm, which is convenient for subsequent pelleting.

3.Wood Drying

Wood waste often contains high moisture levels. Excessive moisture not only hinders the formation of wood pellets during production but also causes the final product to mold and deteriorate during storage. The drying system of the machine will rapidly reduce raw material moisture to approximately 15% through precise temperature control.

4.Pelletizing

We offer wood pellet press for sale with different pellet specifications according to various situations, usually ranging from 2 to 12 mm in size. In the pelletizing section, the wood chips enter the wood pellet press machine through the feeder and are converted into wood pellets under the extrusion of the pressure rollers and the ring die.

5.Pellets Cooling

The freshly produced pellets are at a high temperature and will first pass through a cooling device to reduce their temperature to room temperature. They are then processed through a shaking machine to remove a small amount of dust and crumbs, which can produce the final pellets.

6.Weighting and Packing

After cooling, we can weigh and pack the wood pellets to maintain a sealed state for our products. This prevents the pellets from absorbing moisture for the better storage.