Wood Pellet Production Line

Specifically developed for the utilization of renewable resources

FEED PELLET

brief introduction for Wood pellet production line

The wood pellet production line is a specialized equipment designed to process wood waste such as sawdust, bark, and branches. This production line primarily uses physical compression to transform these materials into high-density, easily storable biomass fuel pellets. The final wood pellets have a high calorific value and burn without sulfur or phosphorus, which makes them an efficient and eco-friendly new fuel. These pellets can be used in industrial boilers, home heating, power generation, etc. With a wide range of applications, they can realize clean energy production and efficient resource recycling.

The RICHI wood pellet production line primarily manufactures wood pellets but can also process other biomass materials such as hay and organic fertilizers.

+86 15038392800

wood pellet Production Line Working Video

The wood pellet production line is a modern and industrialized solution that transforms biomass waste into high-value clean energy.

The wood pellet production line is an integrated industrial system that transforms loose wood raw materials, such as wood chips, shavings, sawdust, and branches, into high-density and uniformly shaped cylindrical solid fuel pellets through a series of physical processing steps.

When selecting a production line, we must consider the type of raw material, production capacity requirements, and local environmental policies to ensure efficient and compliant operations. With growing awareness of environmental protection, the market demand for wood pellet production will continue to expand.

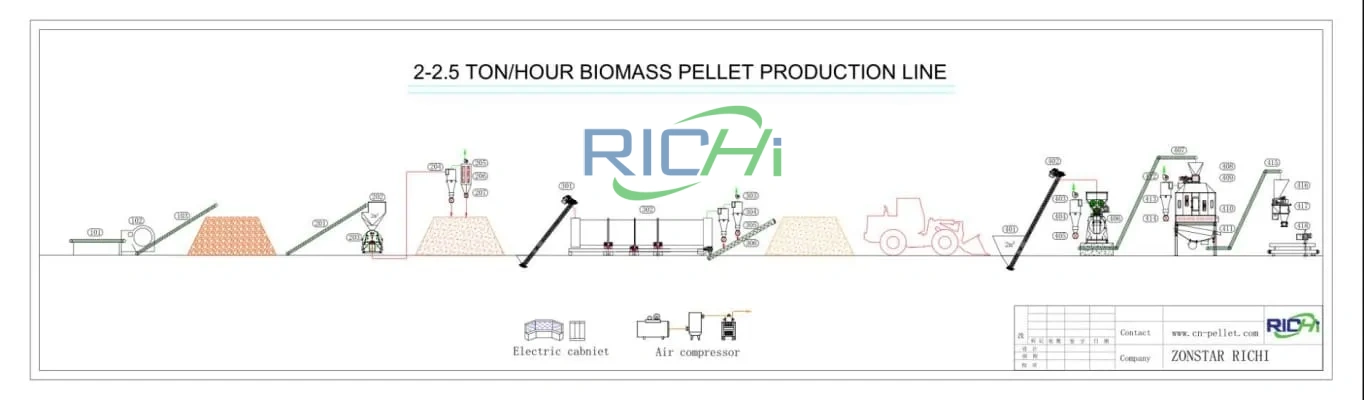

Wood Pellet Production Line Process

Due to variations in production capacity, raw materials, and manufacturing specifications, the required production workflow will differ accordingly. Here I will take raw material as logs as an example and introduce you the process of 2-2.5T/H complete wood pellet plant in detail.

01

Wood Chipping

First of all, the logs enter the chipper through the conveying equipment, the chipper can cut the logs to 3-5mm thin wood chips, which is convenient for the subsequent crushing process, and also beneficial to the drying of raw materials.

02

Wood Crushing

For different types of raw materials, the equipment is provided with different specialized crushing devices. Finally, all raw materials are transformed into powdered material with a particle size of 3-5mm, which is convenient for subsequent pelleting.

03

Wood Drying

This step directly determines the quality and storage life of the final pellets. The drying system of the wood pellet machine will rapidly reduce raw material moisture to approximately 15% through precise temperature control.

04

Pelleting

We offer machines with different pellet specifications according to various situations. In the pelleting section, the wood chips enter the wood pellet machine through the feeder and are converted into wood pellets under the extrusion of the rollers and the ring die.

05

Cooling

The freshly produced pellets are at a high temperature and will first pass through a cooling device to reduce their temperature to room temperature. They are then processed through a shaking machine to remove a small amount of crumbs, which can produce the final pellets.

06

Packing

After cooling, we can weigh and pack the wood pellets. There are typically two packaging methods: wire sealing or plastic packaging. Plastic packaging keeps the product in a sealed state.This prevents the pellets from absorbing moisture for the better storage.

Main Production Line Equipment

Next, let’s explore the core components of RICHI Machinery’s wood pellet production line equipment.

Rotary Drum Drying machine

Rotary drum drying machine is employed to reduce or minimize the liquid moisture content of the material. The wet material is mixed with high-temperature gas in the drying cylinder to evaporate the water.

Ring Die Wood Pellet Machine

The ring die wood pellet machine is a large-scale wood pellet manufacturing machine which is mainly used to process wood chips, branches, firewood, straw, and other materials into wood pellets.

Water-drop Hammer Mill

SFSP series water-drop hammer mill is suitable for to crush the wood forestry wastes ,such as wood logs , and agricultural wastes, such as straw. The crushed materials can be used to make wood pellet.

Drum Chipper

RIGX series drum chipper is a kind of cutting large diameter wood, wood harvesting residues (twigs, branches, etc,) and wood processing residues (skin, slats, log core, waste veneer, etc.) into small Fragmented equipment.

Counter-flow Cooler

RICHI SKLN series counter-flow cooler employs a counter-flow cooling principle to ensure sufficient and uniform cooling of particles. The temperature of the cooled pellets does not exceed room temperature by more than 3–5°C.

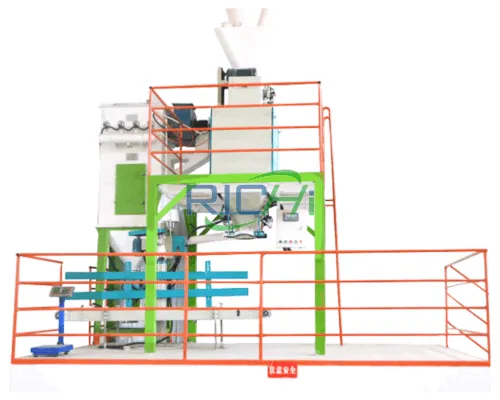

Automatic Packing System

RICHI DCS Series automatic packing system is suitable for quantitative weighing on packing pellets and powder materials. It is a professional quantitative weighing and packaging equipment.

Capacity and Price of Wood Pellet Production Lines

Below is the production capacity range and price range for complete wood pellet production lines for your reference.

Small Equipment Series

- Production Capacity: 300 -500 kg/h

- Price Range: ¥28,000 – ¥160,000

- Features: Typically single equipment or simple combinations with low automation levels require multiple operators for tasks such as loading and packaging. Suitable for individual entrepreneurs, farms, or small businesses utilize local wood waste for production.

Medium-Sized Equipment Series

- Production Capacity: 3-4 t/h

- Price Range: ¥95,000 – ¥430,000

- Features: This is the most common commercial wood pellet production line scale. It consists of a complete equipment system (crushing, drying, pelleting, cooling, packaging) with a high degree of automation. It is the choice for most pellet production enterprises.

Large-Scale Equipment Series

- Production Capacity: 10-12 t/h

- Price Range: ¥280,000 – ¥1,100,000

- Features: Highly automated turnkey projects contains complete automated control systems and dust removal systems. It requires a stable supply of raw materials, which is usually operated by large wood processing enterprises or specialized biomass energy companies.

Wood Pellet Production Line Projects

Below are some projects we have done. If you are interested in these projects, please contact us for more details.

8-10T/H Wood Pellet Production Line in Swedish

- Time: 2024

- Region: Europe

- Background: Sweden possesses abundant forest resources, with numerous sawmills and board plants in the country generating quantities of sawdust and wood shavings. The wood pellet production line primarily processes mixed softwood sawdust sourced from multiple nearby sawmills. The line is equipped with a large raw material silo, multi-stage screening, and iron removal systems, which effectively ensures the purity of the raw material.

5-6T/H Wood Pellet Production Line In Colombia

- Time: 2023

- Region: North America

- Background: Canada has a thriving forestry industry, but in recent years, the mountain pine beetle infestation has resulted in large quantities of dead timber. This project effectively utilizes the wasted disaster wood, and transforms it into a valuable resource. Equipped with large-scale shredders and chippers, the line directly transforms logs and wood blocks into uniformly sized wood chips, which are easy to pelletize in subsequent stages.

1-2T/h Wood Pellet Production Line in Brazil

- Time: 2025

- Region: South America

- Background: Brazil has a large area of planted forests. These trees grow rapidly and have high wood density, which is the ideal raw material for producing pellet fuel. This project utilizes the forest resources of large pulp mills and paper mills. Due to the humid local climate, the project has specifically enhanced the rain and moisture resistance of the raw material warehouses and improved the processing efficiency of the drying stage.

Advantages Of Wood Pellet Production Line

The core advantage of investing in wood pellet lines lies in transforming low-value waste into high-value green energy through mature technology, with a perfect alignment of economic and environmental benefits.

Versatile Applications

Our equipment can be used in multiple industries including wood processing, renewable energy, industrial heating and agriculture. Whatever biomass material you process, we can offer the suitable solution.

Highly Automated

The wood pellet production line operates fully automatically from material feeding to packaging, which only requires 1-2 operators. This saves labor and improves production efficiency.

High Product Value

Processed wood pellets have a high calorific value, which is close to that of standard coal. Their market price is significantly higher than the value of waste wood, and the profit margin is substantial.

Convenient Storage

The produced pellets feature high density, compact size, and uniform shape, which is very convenient for storage and long distance transportation.

Low Material Costs

The primary raw materials for the wood pellet production line are the waste of forest and agriculture. These materials serve as production resources with enormous cost advantages, which might require payment for disposal.

Clean and Eco-Friendly

Compared to coal, wood pellets have low sulfur and minimal nitrogen oxide emissions, so there is no need to worry about failing environmental standards. They truly achieve clean combustion with no burden.

Recycling

What is worthy of our attention is the insignificant ash left after burning. For farmers, they can be directly spread over vegetable gardens and orchards for supplementing nutrients. For landscaping applications, spreading ash from burning materials not only helps control pests but also provides essential nutrients to promote tree growth.

Customized

RICHI offers multiple wood pellet production line design solutions. Customers may select from existing options or ask our industrial machinery designers to customize a solution to your specific requirements.

What Can RICHI Do For You?

RICHI Machinery is a professional team with over 20 years of experience.

- Customized Solutions: We will first discuss raw materials, production goals, and budget in detail with you, then make a customized solution to your needs.

- Modern Workshop: We have a modern production facility, which are able to efficiently and precisely manufacture each machine for you.

- On-site Installation: Once the equipment arrives at the place, our professional technical team will arrive on time to install and test it, strictly following the specifications to make sure that the equipment is stable and reliable.

- Information Sharing: During the production process, we will provide you with timely updates on progress so that you can keep track of the production situation at all times. Once the machines are finished, we’ll pack them up and work with a professional logistic company to deliver them safely and punctually to your appointed place.

- Certificates Obtained: All products have obtained international certifications including ISO, CE, SGS, and BV.

- After-Sales Service: RICHI Machinery promise to provide one year of free service after sale. During this period, if the equipment malfunctions because of the quality or normal use, our after-sales team will give you technical advice within 30 minutes to respond and will try to resolve it remotely by phone or video.

30+

Years Experience

1000+

Serving customers

140+

Exported countries

2000+

Provided devices

Frequently Asked Questions

If you have any other questions, please contact us.

What raw materials can be used?

+

The wood pellet production line has a wide range of raw material, including wood chips, sawdust, shavings, branches, and wood scraps. However, raw material requirements are stringent: materials must typically be in a powder form of 3-5mm in size, with moisture content strictly controlled between 13% and 18%. Excessive moisture prevents proper pellet formation, while insufficient moisture may cause carbonization of the raw material.

Why are the pellets loose and poorly formed after extrusion?

+

Possible causes include: First, the moisture content of raw materials may not be within the optimal range of 13%-18%. It is recommended to purchase a moisture meter for real-time monitoring. Second, the compression ratio required for producing softwood pellets differs from that for hardwood pellets, which requires timely adjustment of the ring die compression ratio. Additionally, a worn die or roll is a common cause of reduced output and discharge difficulties, which requires regular replacement.

Why is the output not reaching the equipment’s rated capacity?

+

There are some possible reasons:

1. Raw material issues: High proportion of hardwood, excessively long fibers, unstable moisture content.

2. Die issues: Incorrect compression ratio used or worn-out old dies.

3. Operational issues: Uneven feed rate, improper die-roll gap adjustment.

Our wood pellet production line’s rated capacity is measured under ideal conditions and with specific raw materials (e.g., pure pine sawdust). Actual output may fluctuate due to variations in raw material composition.